Ramsey Winch 300/H-300 RAM-LOK User Manual

Page 8

8

RE-ASSEMBLING AND CHECKING THE BRAKE

1.

Press brake hub into place over worm shaft and key.

2.

Assemble ball into appropriate slots of cam. (Refer to Diagram 1, Page 5). Use stiff grease to hold balls into place and

slide cam over end of worm. Be sure that balls are secure, between cam slots and hub slots. Refer to Page 7 to deter-

mine proper ball slot setting.

3.

Install brake disc.

4.

Install retainer plate, smooth side toward brake disc.

5.

Install the gasket on the cover with a small amount of grease or sealer.

6.

The coil spring goes over the adjusting screw on the inside of the cover.

7.

Install the notches of the leaf spring on the pins protruding through the cover. The hollow side of the leaf spring goes

toward the brake.

8.

Install brake housing cover, making sure the protruding pins go through the leaf spring and into the holes in the retainer

plate.

9.

Bolt cover into place with the mounting screws. Install drain plug and add 1 pint all purpose E.P. 140 oil.

10.

Turn winch in the hoisting direction at least one turn of the input shaft.

11.

Turn the adjusting screw in until it is finger tight.

TEST FOR PROPER BRAKE ASSEMBLY

After the brake has been adjusted to the proper torque setting disengage clutch. Start vehicle engine and run winch in the reel in

(hoisting direction). Allow winch to run in this direction for one minute.

Place your hand on the safety brake housing. If housing is not hot to the touch then run winch in the reverse direction (cable

out) for one minute. Brake housing should begin to heat.

When these conditions exist, proper installation has been made. If heating becomes noticeable when running the winch in for-

ward rotation (hoisting direction), the brake should be again disassembled. When disassembled, place the brake balls in the

alternate set of slots in the cam plate, then carefully follow the instructions for re-assembling and checking the brake.

INSTRUCTIONS FOR CHECKING ASSEMBLY ARRANGEMENT AND SETTING OF WORM BRAKE

When the worm brake is assembled, the brake must be set with the balls in the #1 or the #2 set of cam slots. (View A-A, Page

7). It is indicated on the name plate whether the balls were installed in the #1 or the #2 slots at the factory.

Three factors determine which slots the balls should be in:

1.

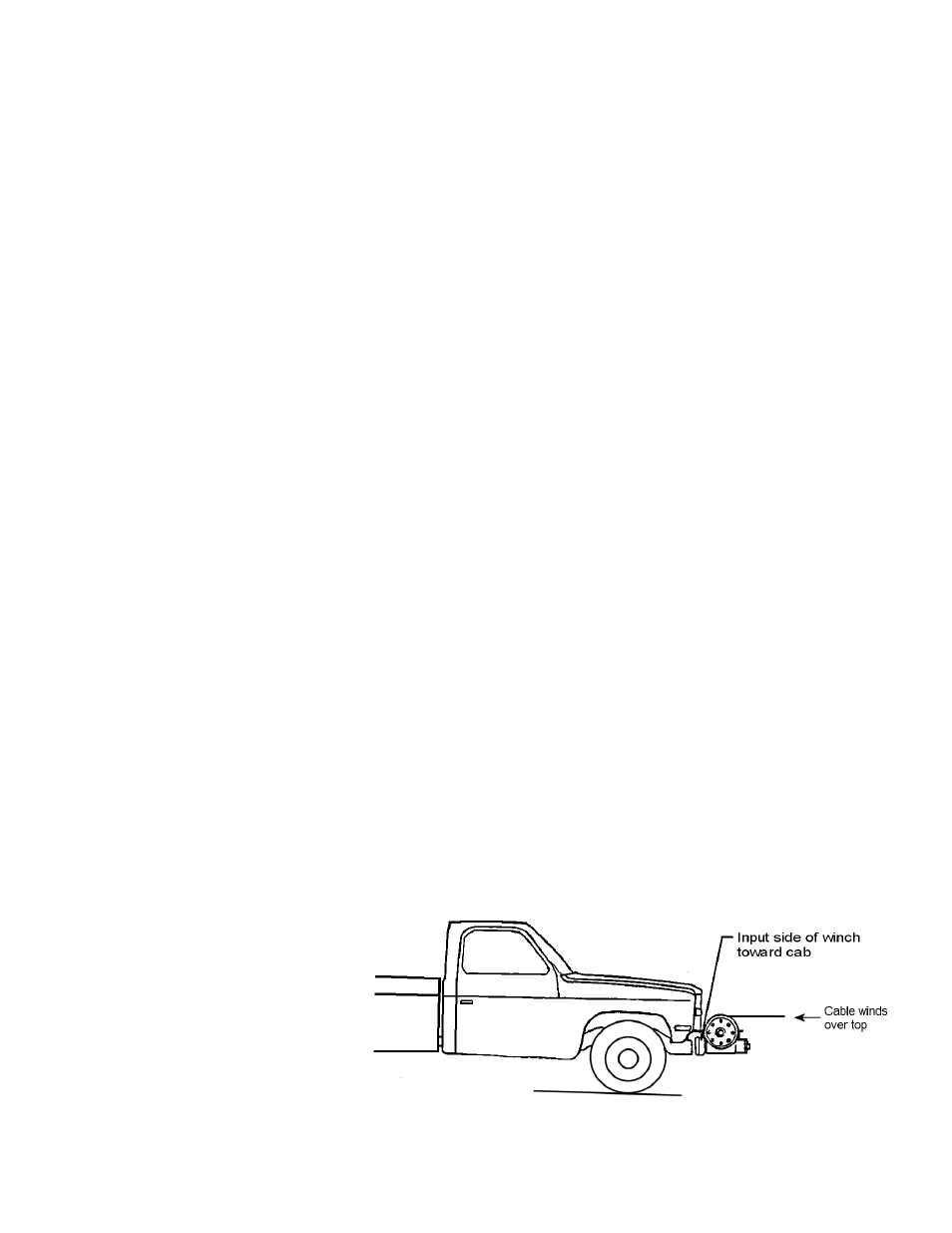

Direction cable winds on the drum. It normally WINDS OVER THE TOP of the drum barrel.

2.

The cut of the gear set, right or left gear. The last letter in the model number of the winch, either R or L, designates right or

left gear set. Example: R-20AR, R-30L, 700R, 800L.

3.

The side of the winch that the input shaft is on. The INPUT SHAFT IN NORMALLY TOWARD THE CAB. Whether the winch

has the gear box on the right or on the left side of the winch does not affect the brake setting.

EXAMPLE: When cable winds over the top of the drum, winch has a right cut gear and input shaft is toward the cab (diagram

2), then the balls need to be in the #2 cam slots.

If any one of these three factors differs from those stated above, the balls need to be in the #1 slots in the cam. A second

change in these factors requires the original

arrangement, and if all three factors are differ-

ent, the balls need to be in the #1 slots. (See

Page 5 and 6 for disassembly and assembly

instructions).

Diagram 2