Ramsey Winch 300/H-300 RAM-LOK User Manual

Page 12

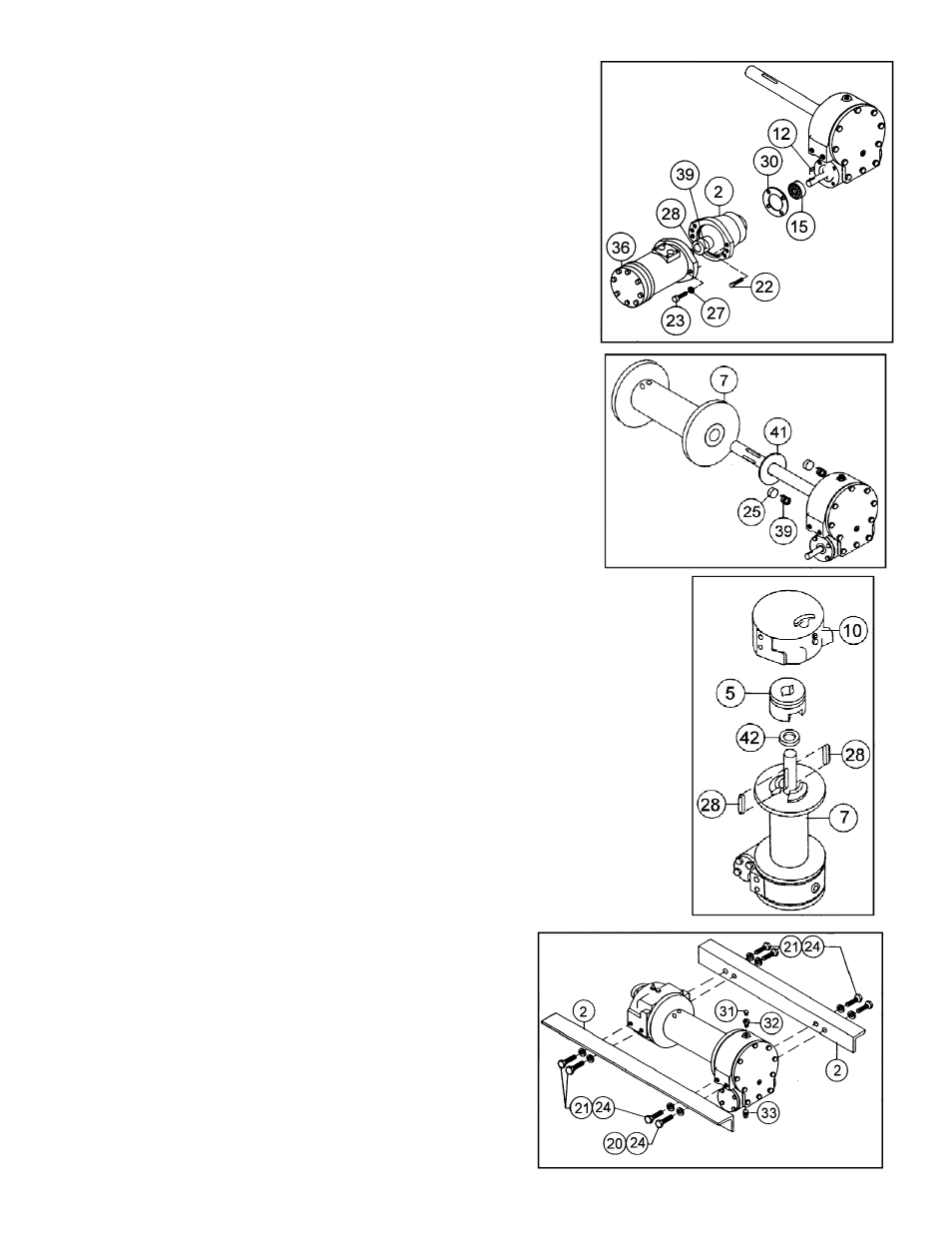

15. Press bearing (item #15) onto worm and into housing. NOTE: Be sure that

thick shoulder of bearings outer race (side with manufacturer's name and

part number) is out, away from worm threads. Place gasket (item #30)

onto adapter (item #2). Attach adapter to gear housing using four (4) cap-

screws (item #22). TIGHTEM CAPSCREWS TO 12FT-LBS. (10.8 Nm.)

EACH. Insert key (item #12) into keyway of keyway of worm shaft. Slide

tapered end of coupling (item #28) over end of worm shaft. Be sure roll

pin (item #39) is in coupling.

Place motor shaft, with key in keyway, into coupling. Secure motor (item

#36) to adapter, using two (2) capscrews (item #23) and lockwashers.

TIGHTEN CAPSCREWS TO 75 FT-LBS. (102 Nm.) EACH.

16. Place winch with gear housing cover down on work bench. Drum shaft

should be in vertical position. Slide thrust washer (item #41) over drum

shaft and slide downward until washer rests on gear housing. Set springs

(item #39) into pockets of gear housing with drag brakes (item #25) on top

of springs. Slide drum assembly (item #7) onto drum shaft with drum jaws

upward.

17. Place thrust washer (item #42) over end of drum shaft and slide downward until spacer

rests on drum. Press drum downward to compress springs in gear housing.

Insert keys (item #28) into keyways with sharp edge of keys pointing outward and

notched end of keys upward. A rubber or brass mallet will be needed to gently tap keys

into position.

Apply grease to keys and end of shaft. Place jaw clutch (item #5) over end of shaft and

slide jaw clutch over keys.

Set clutch housing (item #10) over end of drum shaft. Pull jaw clutch (item #5)

upward, toward clutch housing, enough to allow yoke, in clutch housing, to fit properly in

groove around jaw clutch.

18. Attach two mounting angles (item #2) using six capscrews (item

#21) with lockwashers and two capscrews (item #20). Torque

capscrews to 34 ft-lbs. (46 Nm.) each. Insert plug (item #33) into

bottom of gear housing. Permatex may be applied to threads to

help prevent leakage.

Pour 3/4 pint of SAE 140 E.P. gear oil (1 pint if winch has a brake)

into housing thru hole in top of housing. Insert relief fitting (item

#31) into reducer (item #32). Reducer should then be placed into

hole on top of gear housing. Tighten fitting and reducer securely.

12