Typical layout – Ramsey Winch 300/H-300 RAM-LOK User Manual

Page 5

WINCH MOUNTING

It is most important that this winch be mounted securely so that the three major sections (the clutch housing end, the cable

drum and the gear housing end) are properly aligned.

All standard model DC-200 Series Winches are furnished with recommended mounting angles. Angle size is 1/4 x 2-1/2 x 2-1/2

x 36" (6 x 63 x 63 x 914 mm) Lg. high strength (50,000 PSI [344,500 KPa] yield) steel angle.

5

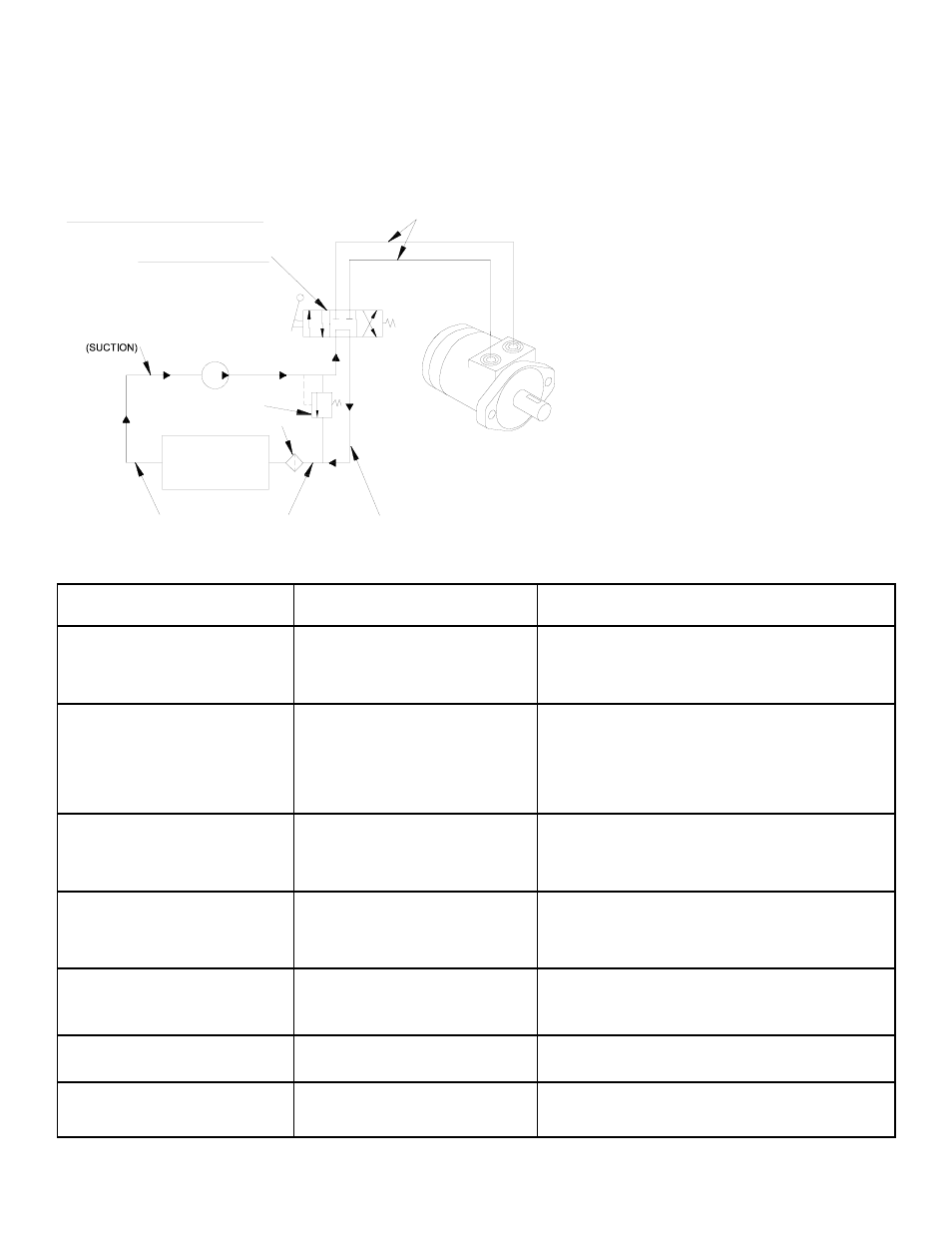

LOW PRESSURE LINES

CONTROL VALVE

RESERVOIR

FLUID

FLUID FILTER

RELIEF VALVE

PUMP INLET LINE

TYPICAL LAYOUT

3 POSITION 4 WAY

PUMP

CYLINDER SPOOL

(.75 I.D. MINIMUM)

LOW PRESSURE LINES

HIGH PRESSURE LINES

(.50 I.D. MINIMUM)

WINCH MOTOR

HYDRAULIC

TROUBLESHOOTING GUIDE

CONDITION

POSSIBLE CAUSE

CORRECTION

CLUTCH INOPERATIVE OR BINDS

UP.

1. Dry or rusted shaft.

1. Clean and lubricate.

2. Bent yoke or linkage.

2. Replace yoke or shaft assembly.

3. Clutch jaws are in contact.

3. See TECHNIQUES OF OPERATION.

OIL LEAKS FROM HOUSING.

1. Seal damaged or worn.

1. Replace seal.

2. Too much oil.

2. Drain excess oil. Refer to TECHNIQUES OF OPER-

ATION.

3. Damaged gasket.

3. Replace gasket.

LOAD DRIFTS DOWN.

1. Safety brake has become worn.

1. Replace brake disc. (See Page 7, Diagram 1).

2. Safety brake out of adjustment.

2. Turn adjusting bolt clockwise 1/4 turn or until load

does not drift.

WINCH RUNS TOO SLOW

1. Hydraulic motor worn out.

1. Replace motor.

2. Low flow rate.

2. Check flow rate. Refer to WINCH MOUNTING

above.

CABLE DRUM WILL NOT FREE

SPOOL.

1. Winch not mounted squarely,

causing end bearings to bind

drum.

1. Check mounting. Refer to WINCH MOUNTING

above.

CABLE BIRDNESTS WHEN

CLUTCH IS DISENGAGED.

1. Drag brake disc worn.

1. Replace discs.

HYDRAULIC FLUID LEAKS OUT

HOLE IN MOTOR ADAPTER.

1. Hydraulic motor shaft seal dam-

aged.

1. Replace seal.