Troubleshooting – Lincoln Electric IM10022 POWER WAVE AC_DC 1000 SD User Manual

Page 45

E-2

TROUBLESHOOTING

E-2

POWER WAVE

®

AC/DC 1000

®

SD

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

USING THE STATUS LED TO TROUBLESHOOT

SYSTEM PROBLEMS

The Power Wave

®

AC/DC 1000

®

SD is equipped with one externally

mounted status light. If a problem occurs it is important to note the

condition of the status lights. Therefore, prior to cycling power to

the system, check the power source status light for error

sequences as noted below.

Included in this section is information about the power source Status

LED and some basic troubleshooting charts for both machine and

weld performance.

The STATUS LIGHT is a dual-color LED that indicates system errors.

Normal operation is steady green. Error conditions are indicated in the

following Table E.1.

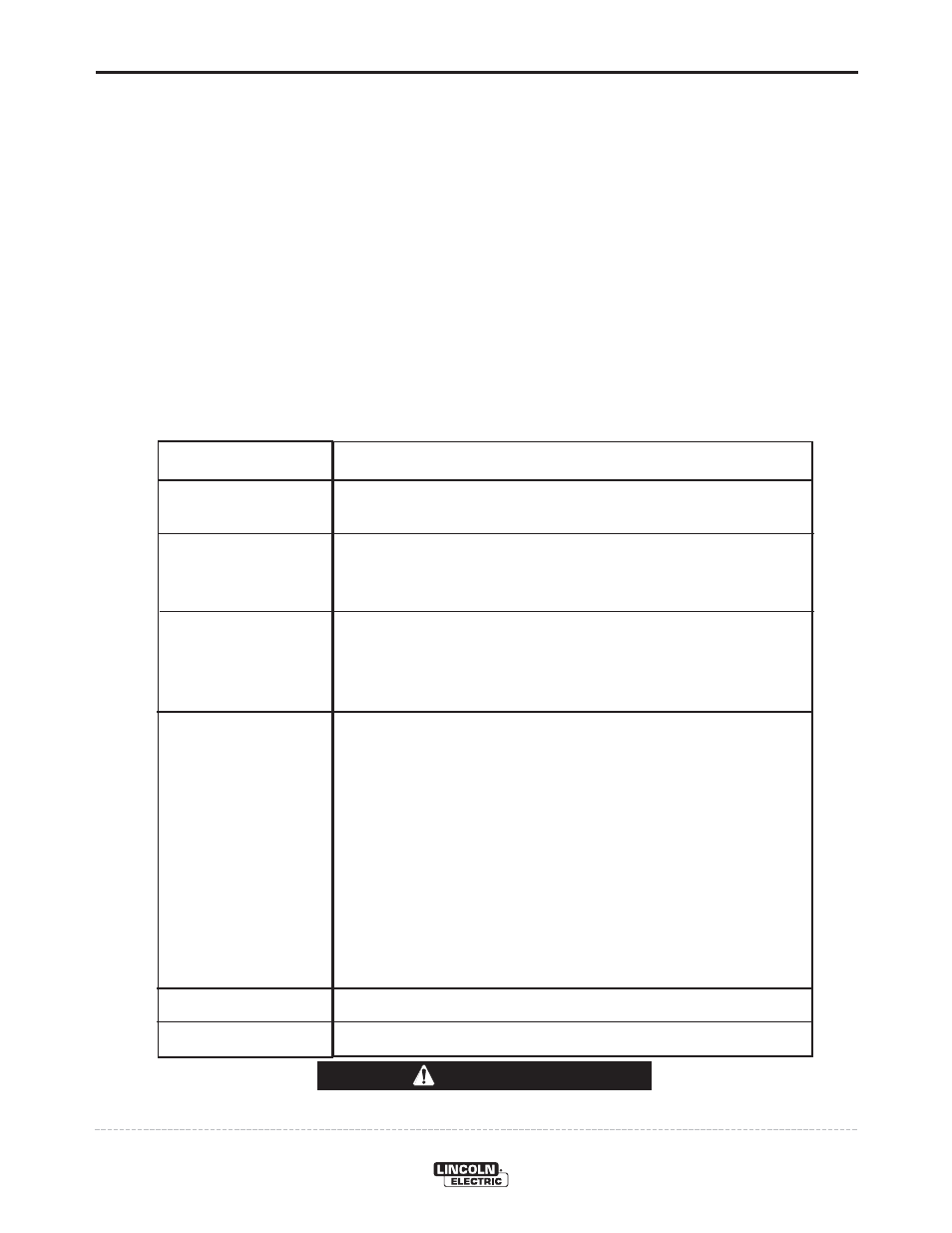

Light

Condition

Steady Green

Blinking Green

Fast Blinking Green

Alternating Green and Red

Steady Red

Blinking Red

Meaning

System OK. Power source is operational, and is communicating normally with all healthy

peripheral equipment connected to its ArcLink network.

Occurs during power up or a system reset, and indicates the POWER WAVE

®

is mapping (identifying) each component in the system. Normal for first 1-10

seconds after power is turned on, or if the system configuration is changed

during operation.

Under normal conditions indicates Auto-mapping has failed. Also used by

Weld Manager and Submerged Arc Cell Setup (available at www.power-

wavesoftware.com) to identify the selected machine when connecting to a

specific IP address.

Non-recoverable system fault. If the Status lights are flashing any combination

of red and green, errors are present. Read the error code(s) before the

machine is turned off.

Error Code interpretation through the Status light is detailed in the Service

Manual. Individual code digits are flashed in red with a long pause between

digits. If more than one code is present, the codes will be separated by a

green light. Only active error conditions will be accessible through the Status

Light.

Error codes can also be retrieved with Weld Manager under System Status

(available at www.powerwavesoftware.com). This is the preferred method,

since it can access historical information contained in the error log.

To clear the active error(s), turn power source off, and back on to reset.

Not applicable.

Not applicable.

TABLE E.1