Operation, Weld sequence, Start options – Lincoln Electric IM10022 POWER WAVE AC_DC 1000 SD User Manual

Page 39: End options

B-9

OPERATION

B-9

POWER WAVE

®

AC/DC 1000

®

SD

WELD SEQUENCE

The weld sequence defines the weld procedure from

beginning to end. The Power Wave

®

AC/DC 1000

®

SD

not only provides adjustment of basic welding

parameters, but also allows the operator to fine tune

the start and finish of each weld for superior

performance.

All adjustments are made through the user interface.

Because of the different configuration options, your

system may not have all of the following adjustments.

Regardless of availability, all controls are described

below.

START OPTIONS

The Delay, Strike, Start, and Upslope parameters are

used at the beginning of the weld sequence to

establish a stable arc and provide a smooth transition

to the welding parameters.

• ARC DELAY inhibits the wire feed for up to 5 sec-

onds to provide an accurate weld start point.

Typically used in multi-arc systems.

• Strike settings are valid from the beginning of the

sequence (Start Button Pressed) until the arc is

established. They control Run-in (speed at which

the wire approaches the workpiece), and provide

the power to establish the arc.

Typically output levels are increased and WFS is

reduced during the Strike portion of the weld

sequence

• Start values allow the arc to become stabilized once

it is established.

Extended Start times or improperly set parameters

can result poor starting

• Upslope determines the amount of time it takes to

ramp from the Start parameters to the Weld

parameters. The transition is linear and may be up

or down depending on the relationship between the

Start and Weld settings.

END OPTIONS

The Downslope, Crater, Burnback and Restrike

Timer parameters are used to define the end of the

weld sequence.

• Downslope determines the amount of time it takes

to ramp from the Weld parameters to the Crater

parameters. The transition is linear and may be up

or down depending on the relationship between the

Weld and Crater settings.

• Crater parameters are typically used to fill the crater

at the end of the weld, and include both time and

output settings.

• Burnback defines the amount of time the output

remains on after the wire has stopped. This feature

is used to prevent the wire from sticking in the weld

puddle, and condition the end of the wire for the

next weld. A Burnback time of 0.4 sec is sufficient in

most applications. The output level for Burnback is

the same level as the last active weld sequence

state (either Weld or Crater).

• Restrike Timer is used to protect the welding

system and/or work piece being welded. If the arc

goes out for any reason (short circuit or open

circuit), the Power Wave

®

AC/DC 1000

®

SD will

enter a Re-strike state and automatically manipulate

the WFS and output in an attempt to re-establish the

arc. The Re-strike timer determines how long the

system will attempt to re-establish the arc before it

shuts down.

• A Re-strike time of 1 to 2 sec is sufficient in most

applications.

• A Re-Strike setting of “OFF” allows for infinite

restriking attempts until a shutdown occurs.

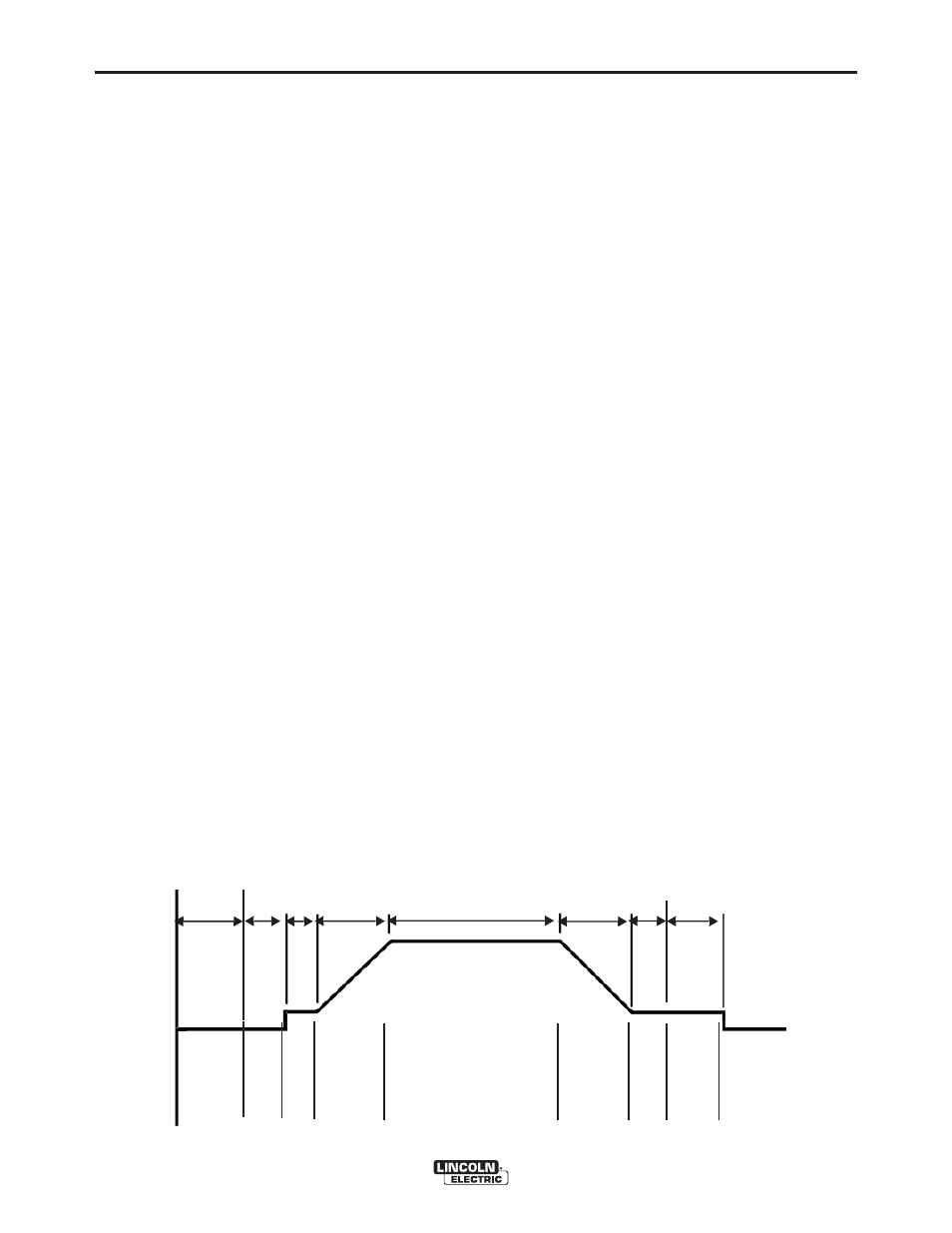

FIGURE B.9 WELD SEQUENCE

O

ut

pu

t

Strike

Upslope

Weld

Downslope

Time

Arc Start

Delay

Start

Crater Burnback

Sta

rtB

u

tt

o

n

Pressed

Wire

Begi

ns

to

F

ee

d

W

ire

T

o

u

che

s

P

la

te

E

n

do

f

St

a

rt

Time

r

End

o

f

Upslope

S

top

B

u

tt

o

n

P

re

sse

d

En

d

o

f

Down

slope

E

nd

o

fCrate

r

Tim

e

r

En

do

f

Burn

b

ack