Operation, B-10, Weld process adjustments – Lincoln Electric IM10022 POWER WAVE AC_DC 1000 SD User Manual

Page 40: Ac adjustments, Wave balance, Dc offset, Frequency

B-10

OPERATION

B-10

POWER WAVE

®

AC/DC 1000

®

SD

WELD PROCESS ADJUSTMENTS

Depending on the weld mode, there are a number of

adjustments that can be made, including but not

limited to Current, Voltage and WFS. These

adjustments apply to either AC or DC processes, and

control the basic parameters of the weld.

AC ADJUSTMENTS

In addition to the basic weld parameters, there are a

number of unique adjustments related to the AC

waveform of the Power Wave

®

AC/DC 1000

®

SD.

These adjustments enable the operator to balance the

relationship between penetration and deposition to

tailor the output for specific applications.

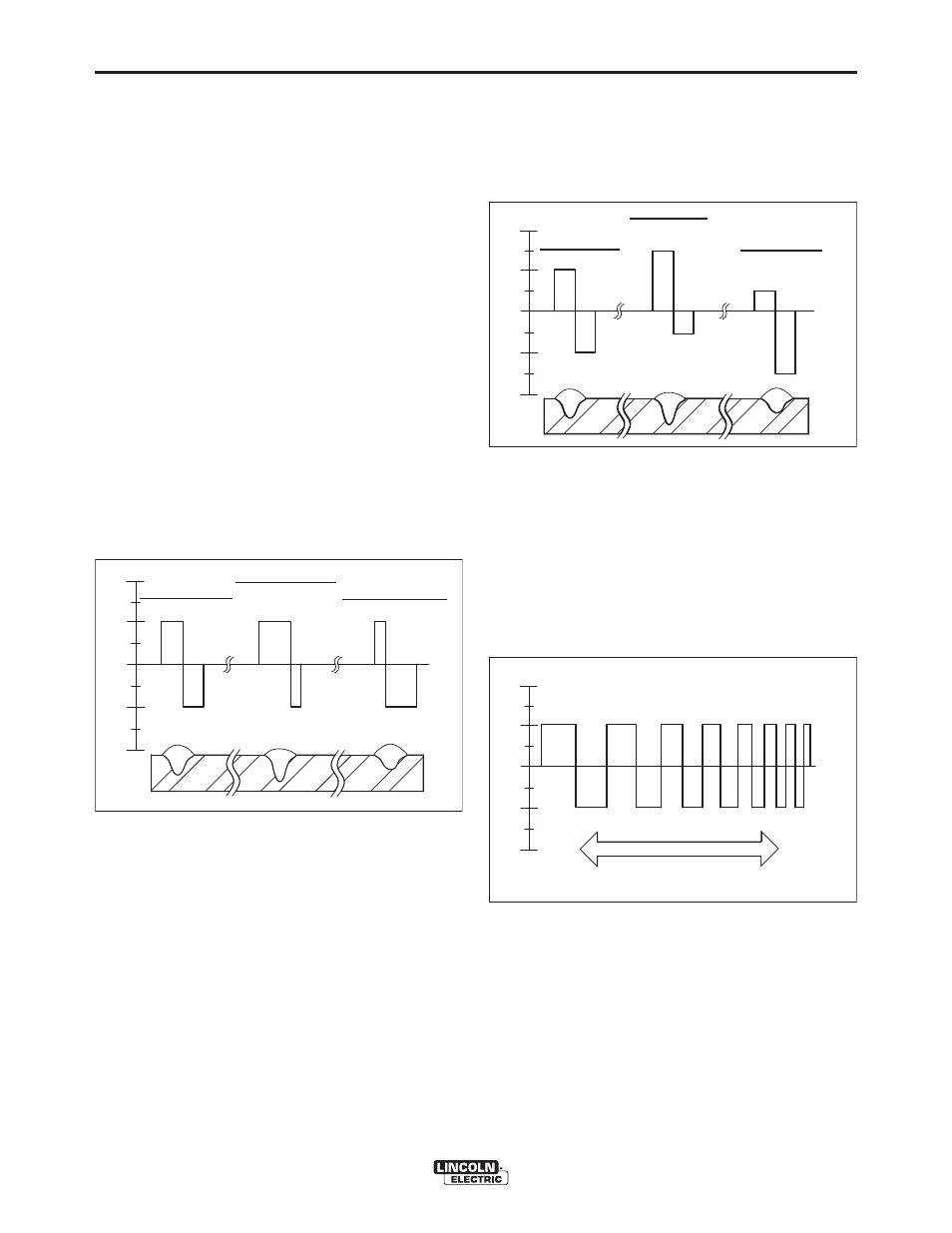

WAVE BALANCE

• Refers to amount of time the waveform spends in

DC+ portion of the cycle.

• Use Wave Balance to control the penetration and

deposition of a given process. See Figure B.10.

DC OFFSET

• Refers to +/- shift of the current waveform with

respect to the zero crossing.

• Use Offset to control the penetration and deposition

of a given process. See Figure B.11.

FREQUENCY

• Power Wave

®

AC/DC 1000

®

SD can produce Output

Frequencies from 20 - 100Hz

• Use Frequency to help provide stability.

• Higher frequencies in multiple arc setups can help

reduce arc interaction.

• Lower frequencies will help overcome output limita-

tions due to inductance in the Weld Circuit. See

Figure B.12.

FIGURE B.10 - WAVE BALANCE

500

-500

0

-1000

1000

Nominal Balance

Increased Balance

More Penetration

Less Deposition

Decreased Balance

Less Penetration

More Deposition

FIGURE B.11 - DC OFFSET

500

-500

0

-1000

1000

Nominal Offset

Positive Offset

More Penetration

Less Deposition

Negative Offset

Less Penetration

More Deposition

FIGURE B.12 - FREQUENCY

500

-500

0

-1000

1000

Use Frequency to fin e tune stabilit y of

imb alanced waveform s and multipl e arc syst ems

Increase

Decrease