Warner Electric ERD Size 060 to 300 User Manual

Page 6

4 Warner Electric Europe • +33 (0)2 41 21 24 24

P-2060-WE • 2/13

6

Options

6.1

Torque adjustment

Torque adjustment is only possible on

VAR02 (~ 50% of nominal torque).

Brakes are supplied adjusted to nominal torque.

Principle of torque reduction:

On VAR 02 (table 3), undo the adjustment ring

located at the rear of the inductor (see chapter 7).

Standard version

6.2

Detection kit

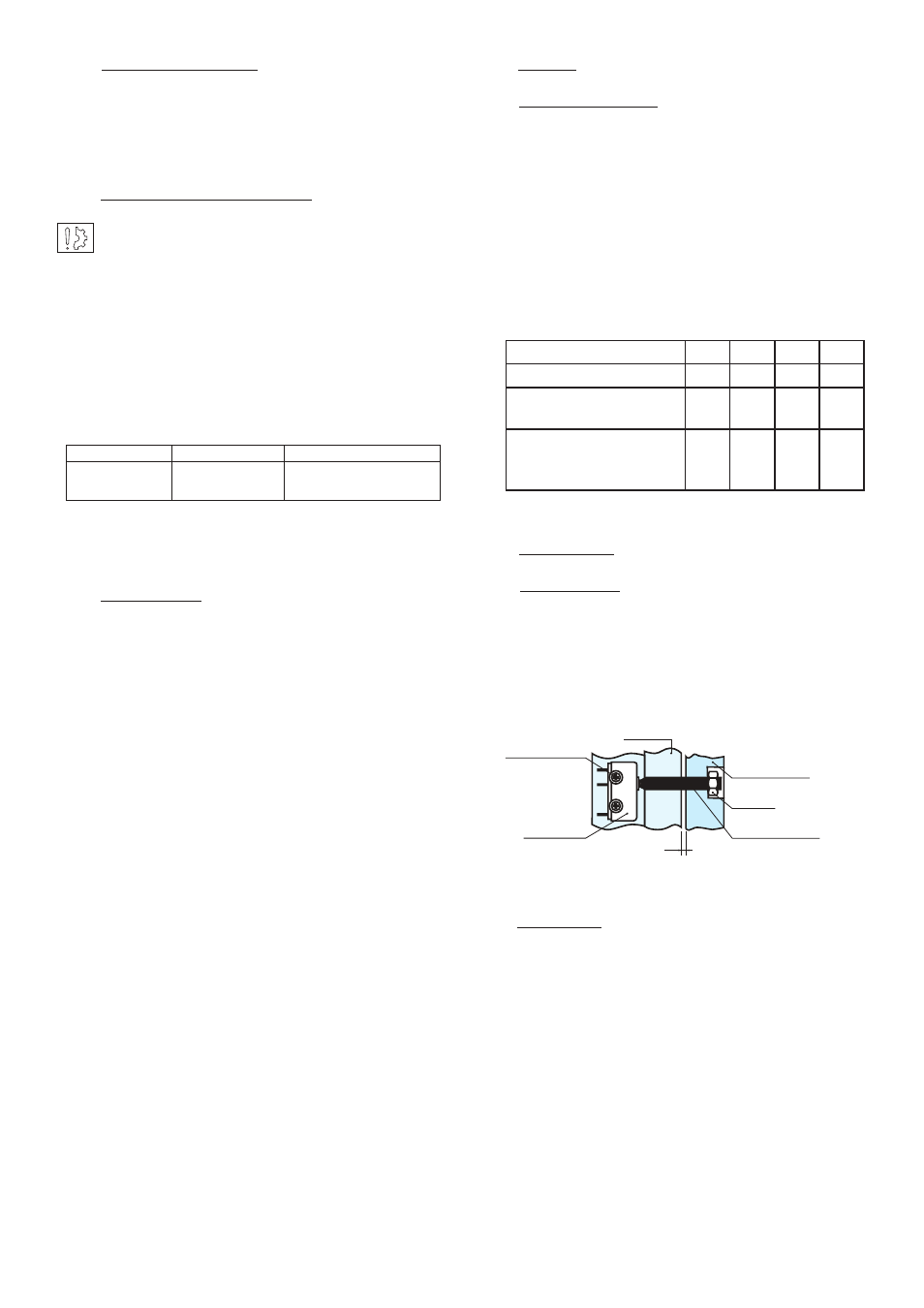

Fitting (Fig. 4)

Check that the brake is correctly set to the

nominal airgap. Tighten the M6 bolts in the

moving armature then fit the nut (see Fig. 4), then

fix the sensor using the M3 bolts and washers.

Adjustment

Insert a shim 0,15 mm thick near to the bolt

between the face of the inductor and moving

armature. Switch the device on, tighten the bolt

to contact with the sensor until the switch point is

obtained then lock the bolt using the nut.

Check correct operation by making several

successive starts and releases.

5

Electrical connection

ERD brakes have to be supplied with direct

current and are factory fitted with 400 mm long

wires. The polarity does not affect operation.

5.1

Important recommendations

All works on the electrical connections have to

be made with power off.

Ensure compliance with the nominal supply

voltage (inade quate supply causes a reduction

in the starting distance).

The connecting wires should be of sufficient

diameter to prevent voltage drops between the

source and equipment supplied.

Tolerance for the supply voltage to the brake

terminals +5% / -10% (NF C 79-300).

5.2

Power supply

We

advise the use of

Warner Electric CBC 140-

1, CBC 140-2 or CBC 140-5 supply units (with

overexcitation and holding voltage)

The supply and switching method has a great

influence on the response time. Response times

shown in our cat alogues are for a supply at

nominal voltage with DC side switching.

In the event of AC switching, the braking

response time may be multiplied by 6.

To get very short brake release and braking

times, we advise the CBC 140-5 (please ask):

•

With overexcitation on brake release, the start

time can be divided by 3 (according to the

supply voltage)

• Adjusting the hold voltage to 50% of

the nominal voltage reduces the brake

engagement time and its temperature rise

Warner Electric supply units provide protection

for coils and circuits. Where a brake is used

without our supply units, with switching on the

DC, it is essential for the coil to be protected

against surges by a varistor fitted in parallel.

I (A) / L (m)

0 to 10 m

from 10 to 20 m

0 to 3 (A)

1,5 mm

2

1,5 mm

2

3 to 6 (A)

1,5 mm

2

2,5 mm

2

Table 3 (VAR 02)

Fig. 4

M5 screw

Nut

Moving

Armature

Magnet

Switch

Screw

washer M3

X

ERD Size

005

010

020

035

Nominal torque (Nm)

5

10

20

35

Max. number of turns

(adjustment ring)

4

4

4

4

Theoretical reduction in

torque for 1 turn of the

nut (Nm)

0,5

1,3

1,25

2,4