Warner Electric AT Clutch – Major Service Sizes 25, 55, 115 User Manual

Page 7

7

Warner Electric •

800-825-9050

819-0324

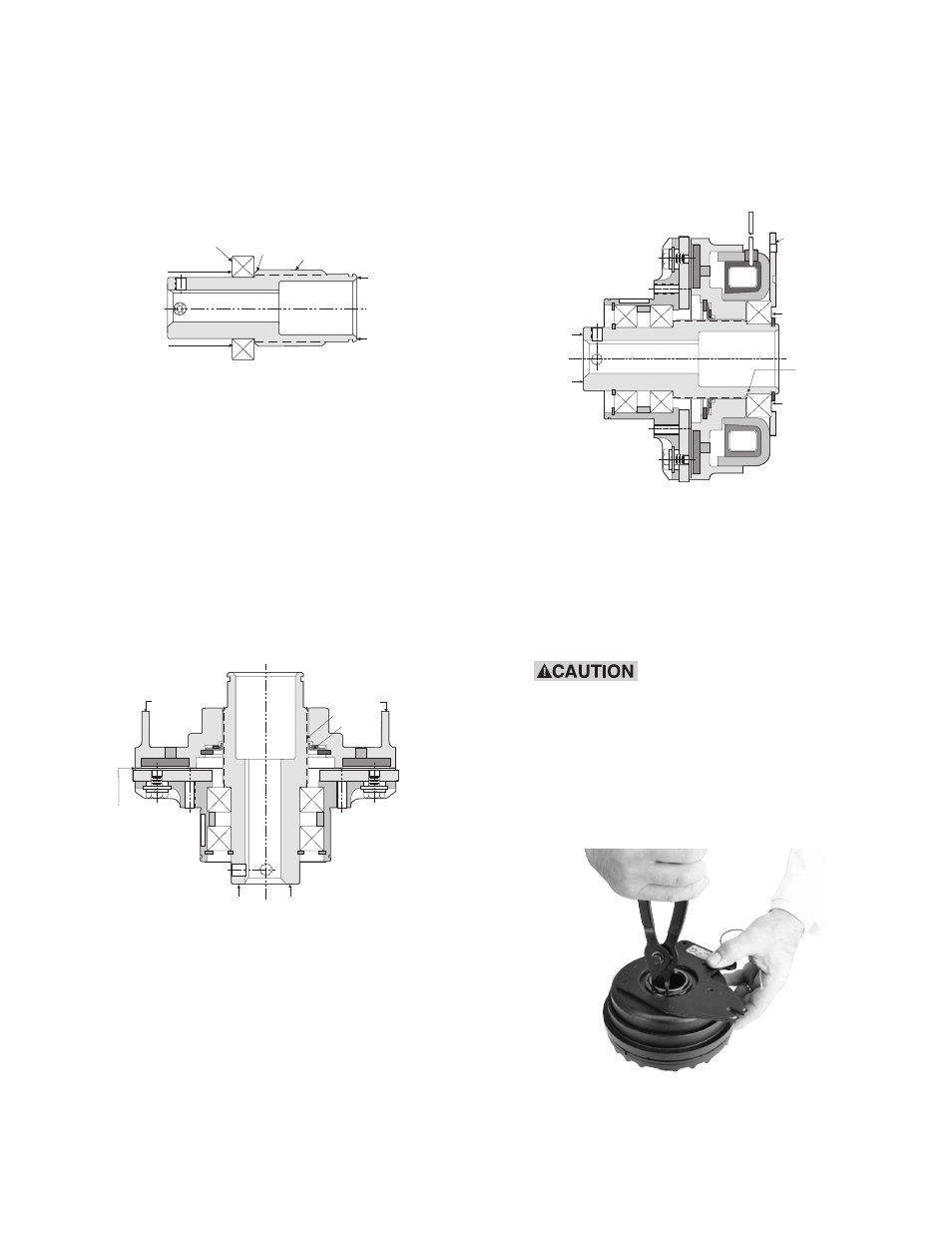

Note: The Armature Assembly must rotate

freely on the hub. Inspect to insure that

the inner bearing is still firmly located

against the hub shoulder as previously

shown in (Figure 1). When inspecting,

place unit firmly on flat surface with

exposed hub end up.

Figure 1

23. Install the rotor assembly onto the hub (Item

6) making sure that the spline teeth are

aligned. When the Autogap detent ring (item

8-3) contacts the spline outside diameter,

press by hand evenly on the rotor until the

friction disc contacts the armature. Release

pressure. Support as shown. The rotor will

spring back approximately .050”. The

Autogap is now set. When the hub is rotat-

ed by hand, the armature and the friction

disc must not touch. (See Figure 6)

Figure 6

24. Press the field assembly onto the hub by

pushing the inner race of the bearing

while supporting on the hub. Apply force

until the inner race of the bearing is located

flush against the shoulder adjacent to the

spline. (See Figure 7)

Figure 7

Install the retaining ring (Item 11) on the hub

with snap ring pliers.

Rotate the hub. No interference between

the shell and rotor is allowable.

When installing or remov-

ing this or other retaining rings, be sure

to hold the ring with one hand so it will

not spring away, endangering personnel

and property, should the pliers lose their

grip on the ring. Safety glasses should

always be worn when installing or

removing retaining rings.

Support

Support

Press

Force

Bearing

Hub

Shoulder

Hub

Press

Force

SUPPORT

MAXIMUM

.050 AIRGAP

ALL AROUND

PUSH

PUSH

SPLINE

DETENT

RING

SUPPORT

SUPPORT

PRESS

FORCE

SHELL

ASSEMBLY

PRESS

FORCE

SUPPORT

UNTIL FLUSH