Coil data – Warner Electric ER 825 and 1225 Normal Duty User Manual

Page 9

9

Warner Electric • 800-825-9050

P-250 • 819-0122

When the brake armature cannot be visually

observed during brake voltage adjustment, an

ohmmeter can be used to determine when the

armature disengages. One ohmmeter lead should

be attached to the armature itself, in a manor not

to obstruct the movement of the armature. The

release point can be determined as follows:

Put machine in a safe condition

so that when voltage is applied to control

and switch closures are made the brake does

not rotate and machine does not run.

1. The brake is engaged when the armature

contacts the magnet, causing very low resistance

(less than one Ohm).

Section V

Ohmmeter Procedure to Detect Armature Release

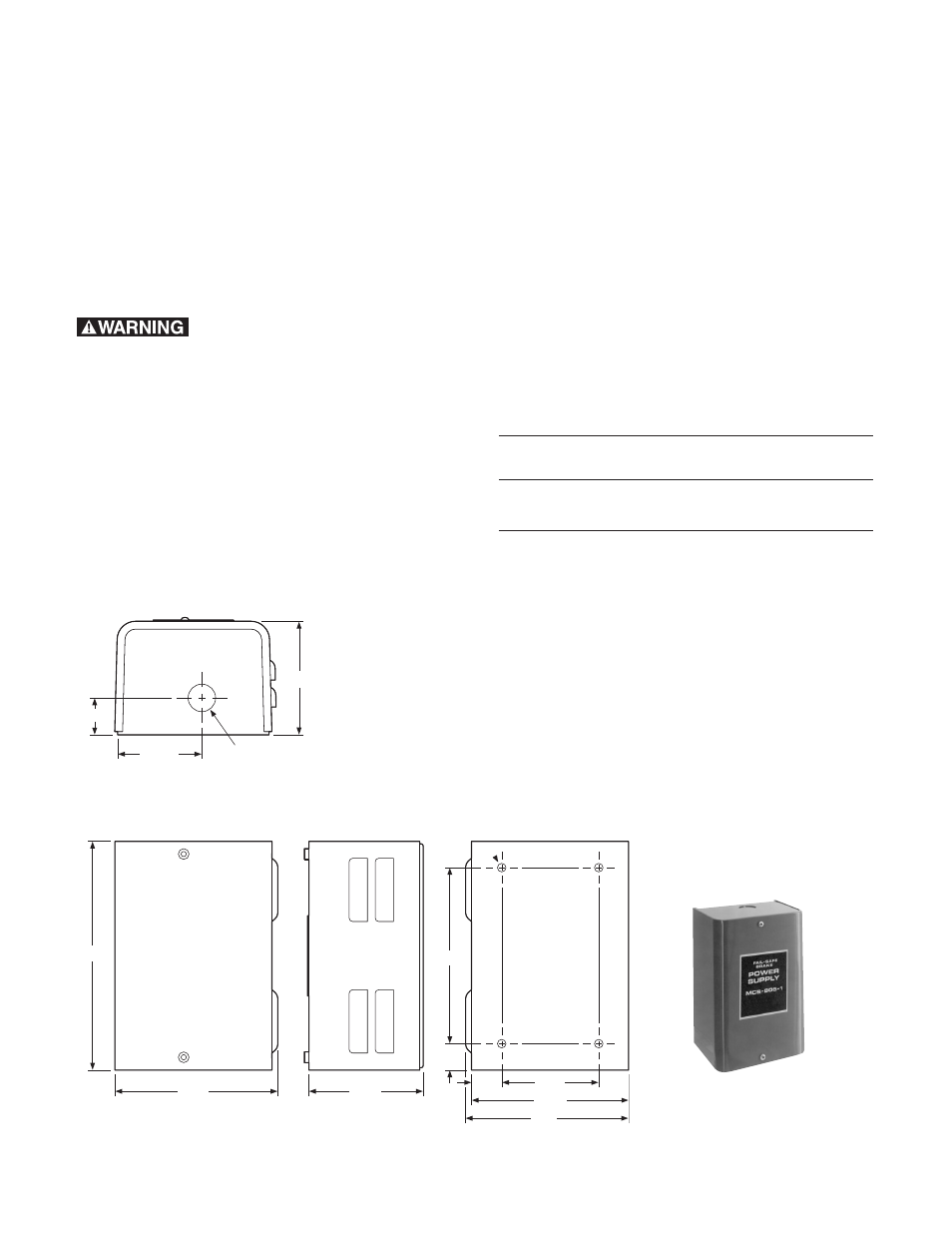

MCS-805-1 and MCS-805-2 Power Supply

Dimensional Drawings and Mounting Provisions

2. The brake is disengaged (released) when the

Ohmmeter indicates higher resistance (usually

greater than one Ohm—may be as high as 10,000

Ohms).

The difference between ohmmeter readings 1 and

2 must be large enough to reliably indicate

armature engagement or disengagement. Reliable

readings can usually be obtained from a brake

mounted on a shaft running on anti-friction

bearings.

Coil Data

Unit

Current Draw (amp)

Resistance (ohms)

Size

at 60 Volts D.C.

at 20°C (±10%)

ER-825

.308

195

ER-1225

.256

235

0.875 Diameter Knockouts

for 0.50 Conduit

Both Ends Typical

0.28 Diameter

(4) Mtg Holes

Clearance for

.25" Screw

TOP AND BOTTOM

FRONT

SIDE

BACK

3.44

2.625

1.125

7.125

5.0

3.44

0.56

6.0

4.81

5.0

3.75

0.53