Warner Electric ER 825 and 1225 Normal Duty User Manual

Page 10

10

Warner Electric • 800-825-9050

P-250 • 819-0122

Section VI

Operating Instructions

When an Electrically Released Brake is properly

installed, no further servicing, lubrication, or

maintenance should be required throughout the

life of the unit.

A worn out Electrically Released Brake can lose its

ability to produce adequate torque. Consequently,

it is imperative that the brake be inspected

frequently for wear and to insure that it engages

and disengages properly. The frequency of

inspections is dictated by usage; a brake used in

a high cycle rate and/or heavy load application

must be inspected more often than one used less

severely. Sound maintenance practices will

determine proper inspection intervals.

Torque loss can result if the armature and magnet

wear extensively enough to cause the detent to

move off the end of the hub spline, resulting in a

loss of the autogap function. The end of normal

service will occur when the armature wears

through the friction material and into the coil,

causing an open circuit and failure to release

when voltage is applied.

Brake wear is determined by two checks. The first

determines whether the brake is about to lose

torque; the second assures that the armature has

not worn through the friction material,

endangering the coil. If either of these checks

indicates excessive wear, the unit should be

replaced.

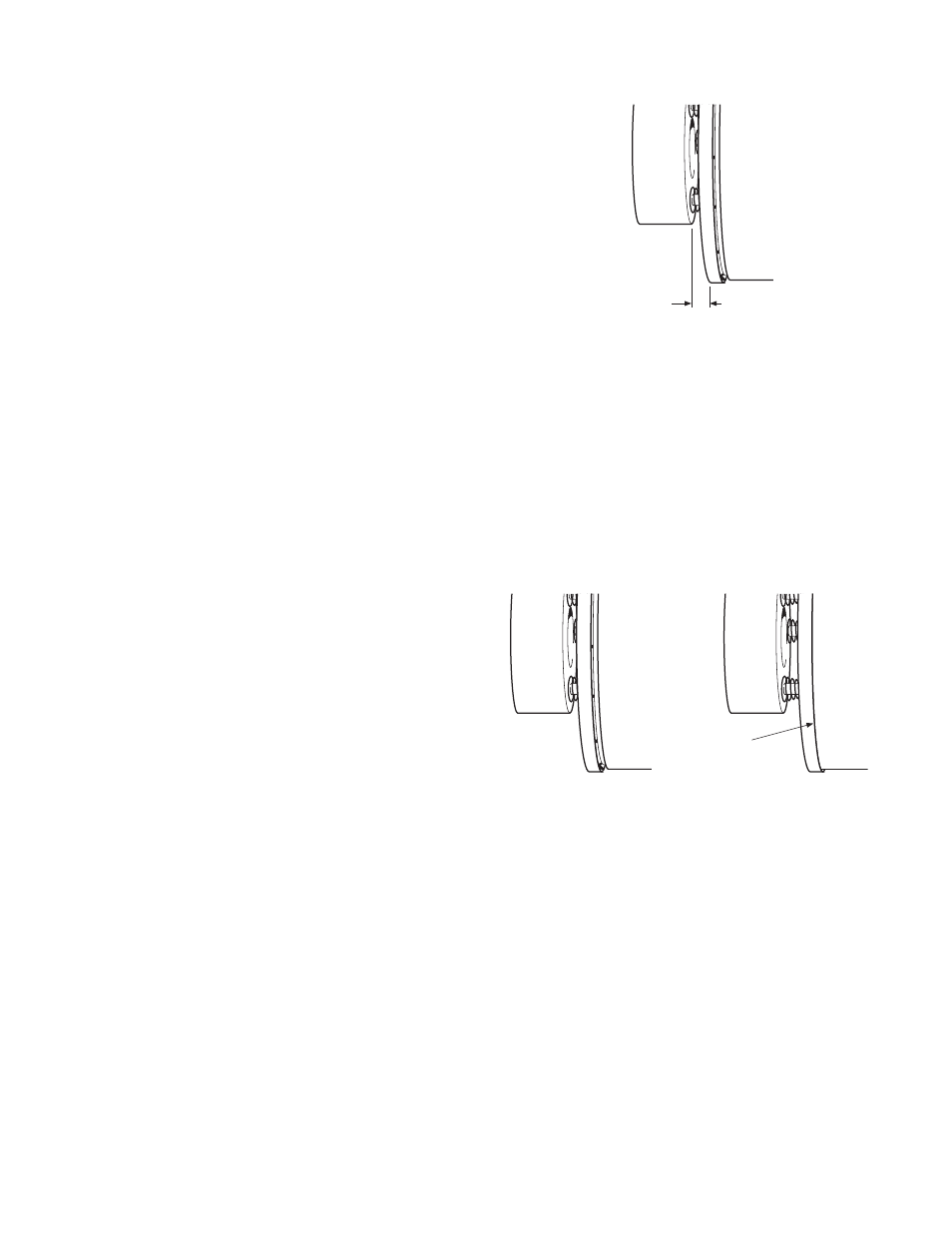

Check No. 1

Measure the distance from the armature hub to

the back of the drive bushing in the armature. If

this dimension equals or exceeds .281 inch

(7.14mm), the armature must be readjusted.

Disassemble per Section III Steps 1 & 2 and

relocate brake armature as indicated starting with

step 1-7.

Check No. 1

Check No. 2

The remaining wear life of the friction surfaces can

be estimated by checking the step machined on the

O.D. of the brake magnet where the armature and

magnet meet. This step is approximately equal to

the friction material thickness. When this step is

completely covered by the armature (worn down)

with the brake engaged, the brake is worn out and

should be replaced.

Check No. 2

Note: New Autogap Assemblies should also be

installed when the armature and magnet are

replaced. Reusing the old Autogap Assemblies

may prevent the armature from fully engaging the

magnet, resulting in torque loss.

Foreign Materials: If units are used on machinery

where fine, abrasive dust, chips, oil or grit are

dispelled into the atmosphere, a protective screen

around the unit is necessary.

Where units are

used near gear boxes or transmissions

requiring frequent lubrication, means should

be provided to protect the friction surfaces

from oil and grease contamination (contact) to

0.281

(7.14)

Max.

New

Worn Out

Magnet Worn

to Step