Warner Electric ER 825 and 1225 Normal Duty User Manual

Page 3

3

Warner Electric • 800-825-9050

P-250 • 819-0122

Sizes ER-825 and ER-1225 with Pin

Drive Armatures Installation Instructions

Basic Mechanical Considerations

Electrically released brakes require special

mounting considerations. Please review the

items listed below prior to starting installation

contained in steps 1-12.

A. If the brake magnet is to be mounted to

a surface of magnetic material, isolate

the brake approximately 1/2 inch from

the surface with a plate or spacer of

non-magnetic material.

B. If a choice of armature shaft material exists,

this should also be non-magnetic. Materials

such as type 302-304 stainless have been

used very successfully.

C. In order to minimize stray flux, the unit should

be exposed as much as possible or, if

enclosed, it should be placed in a housing of

non-magnetic material such as stainless steel

or aluminum.

D.

must be exercised when the

armature is moved close to the magnet

assembly since the permanent magnets

create a very strong attractive force. Injury

may result if fingers are in between the

armature and magnet when the gap is 1/2"

or less.

E.

Foreign Materials: If units are used on

machinery where fine, abrasive dust, chips,

oil or grit are dispelled into the atmosphere,

a protective screen over the unit may be

necessary.

Where units are used near

gear boxes or transmissions requiring

frequent lubrication, means should be

provided to protect the friction surfaces

from oil and grease to prevent serious

loss of torque.

Applications requiring a

vertical shaft mounting must be reviewed

and approved by Warner Electric

Applications Engineering.

Section I

Assembly

Step 1:

Check to insure that the magnet and its

mounting surface are clean and free from

burrs.

Step 2: Bolt the magnet in place with capscrews

and lockwashers.

Note: The magnet pilot diameter must be

concentric to the shaft within .010 inch T.I.R.

The magnet mounting surface must be square

with the shaft within .006 inch T.I.R. measured

at the bolt circle.

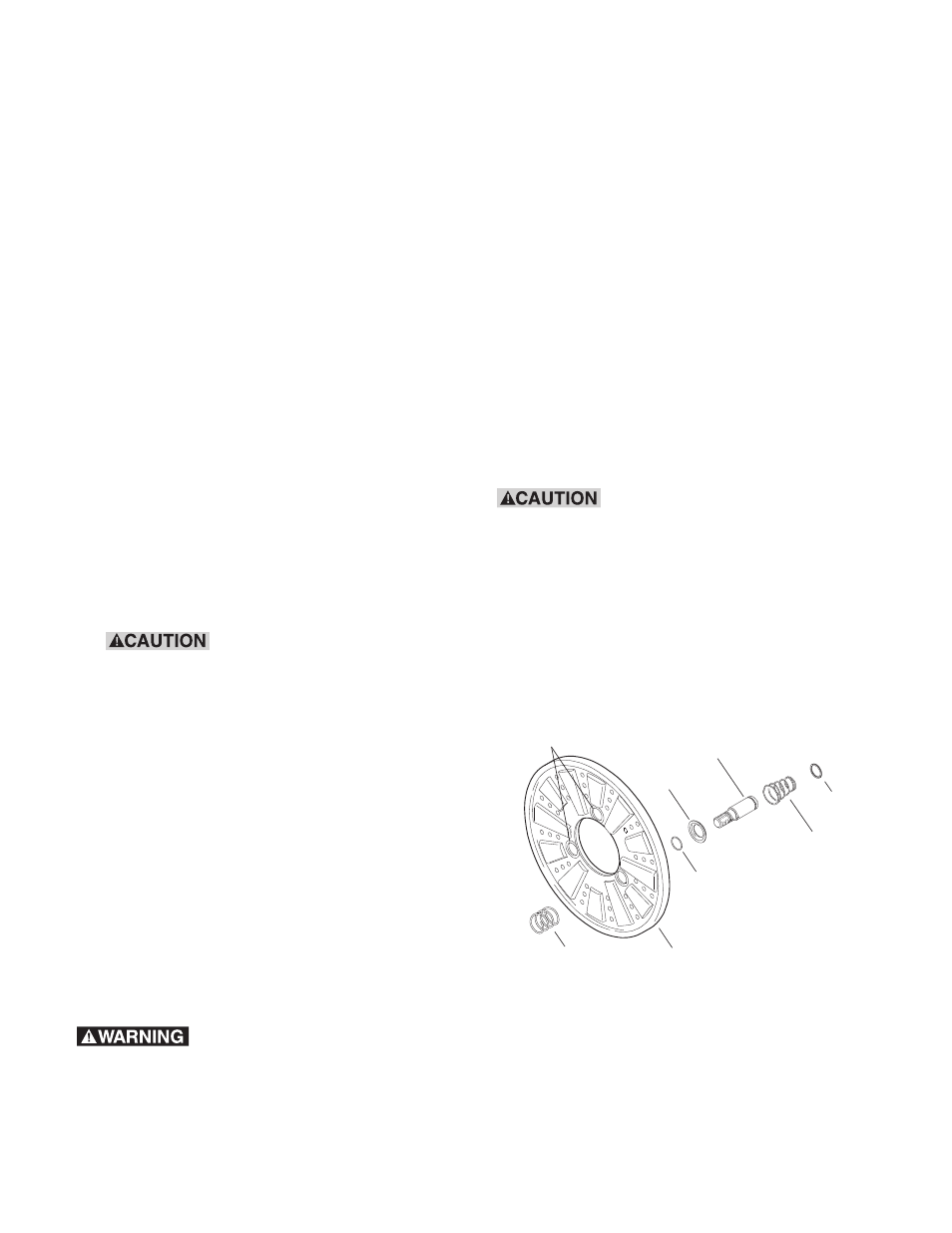

Step 3: Assemble the armature to the armature

hub with the autogap mounting accessory as

follows:

New armatures shipped from

the factory are flat to within .005 inch and

this flatness must be retained to maintain full

torque. Any attempt to pry the armature

loose from the magnet will distort the

armature. When adjusting the armature

position, apply any required force only to the

hub, not to the outer edge of the armature.

Also, use care when handling the armature

as dropping may also cause distortion.

Note: Failure to set control voltage using the

step by step procedures in this manual may

cause overheating and premature failure.

Step 3A: Place straight springs (white) over

each armature boss on the back side of

the armature.

Armature Boss

Straight Spring

(White)

Detent Spring

Retainer

Retainer

Ring

Detent

Spring

Drive Pin

Heavy

Spring

(Red)

Armature