Warner Electric ER 825 and 1225 Normal Duty User Manual

Page 11

11

Warner Electric • 800-825-9050

P-250 • 819-0122

prevent serious loss of torque by reducing the

coefficient of friction and swelling the friction

material. Small amounts of oil and grease

accidentally reaching the friction surfaces may be

removed by wiping with a rag dampened with a non

petroleum, non residue cleaning solution. In

performing this operation, do not drench the friction

material. If the friction material has been saturated

with oil or grease, no amount of cleaning will be

completely effective. Once such a unit has been

placed back in service, heat will cause the oil to be

boiled to the surface resulting in further torque loss.

This unit should then be replaced!

Fails to Release: If an Electrically Released Brake

does not release, the initial check should be to verify

the electrical connections (polarity) between the

brake coil and power supply. If the lead wires are

connected properly power supply positive (+)

terminal and brake coil (+) terminal, and power

supply negative (-) terminal and brake coil (-)

terminal, the next check is to see that the brake

release voltage adjustment is properly set in

accordance with installation instructions (see

Table of Contents).

If readjustment of the control output does not release

the brake and an AC input to the control is present,

a further check should be made to determine if the

control is faulty as follows:

Put machine in a safe condition

so that when voltage is applied to control and

switch closures are made the brake does not

rotate and machine does not run.

Connect a DC voltmeter across the brake magnet

terminals (do not disconnect the leads to the

terminals). Turn the torque adjustment on the control

fully counterclockwise, then slowly turn the

adjustment screw clockwise—the voltmeter should

indicate a voltage range from approximately 30 to 75

volts for the MCS-805 series and 0 to 90 volts using

other variable supplies.

To determine if there is current flow through the

magnet coil. Further checks may be made as

follows: a low-range (.1 to 1 amp) amp meter should

be connected in series with one wire to the magnet.

The Coil Data chart (page 9) lists the correct ratings

for the various sizes. These readings are with the

power on and the brake release adjustment turned

clockwise, until a voltmeter attached to the brake

magnet terminals reads 60 VDC. If no ampres are

read, an Ohm reading of the magnet coil should

be taken. Ohmmeter checks should be made with

the power off and circuit open (to be certain,

disconnect one lead wire to the coil). Refer to the

Coil Data chart (page 9) for the specifications of

the appropriate unit. A very high or infinite

resistance reading would indicate an open coil.

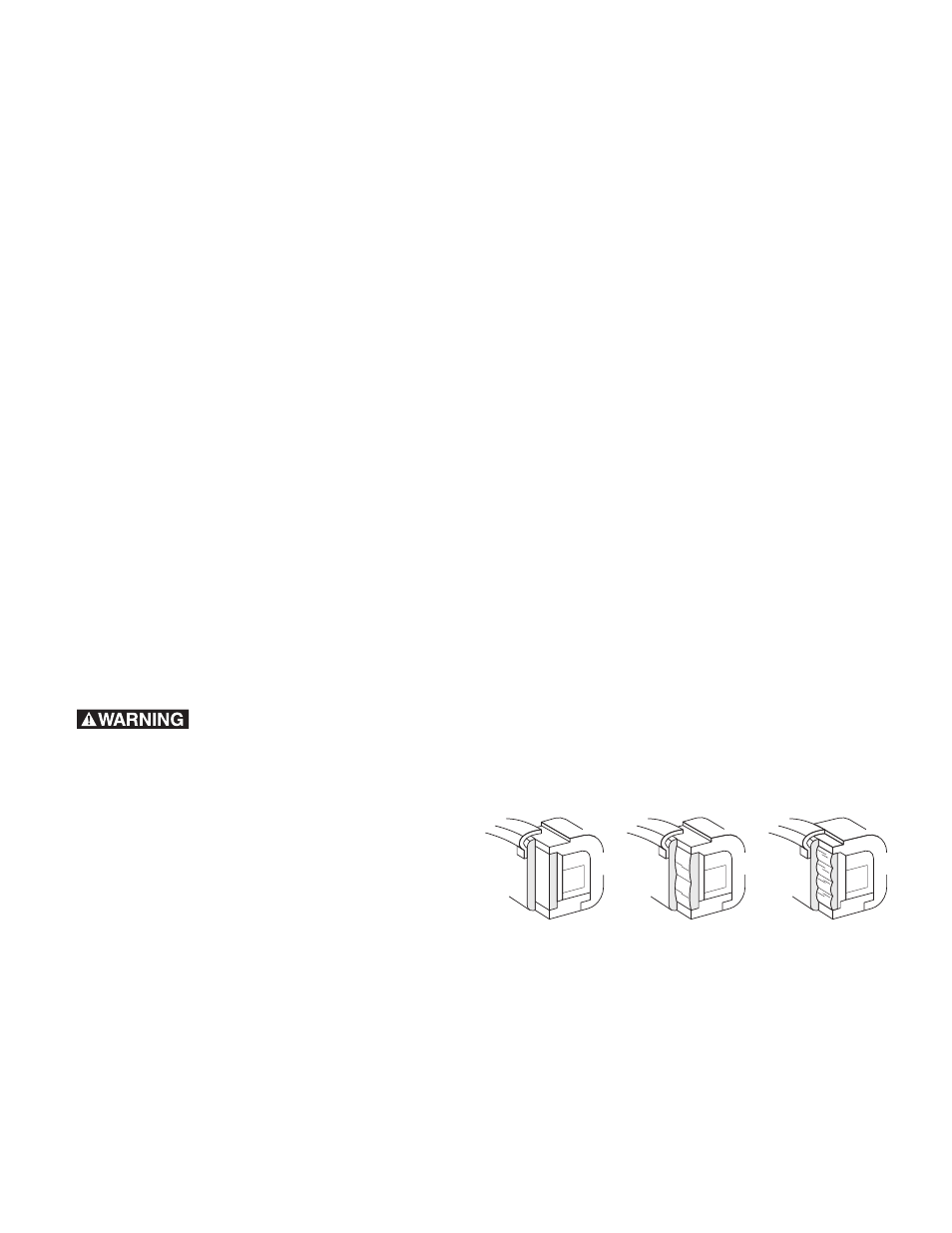

Wear Pattern: (Figure 4) As the brake is used

wear grooves will appear on the friction surfaces.

This is a normal condition, and does not impair

functioning of the unit.

Never machine the

friction surfaces to remove grooves or score

marks resulting from normal wear.

There are two main wear parts, magnet and

armature. When either is worn out, the

complete brake must be replaced.

Heat: Excessive heat and high-operating

temperatures are causes of rapid wear. Air should

be allowed to circulate around the unit as

efficiently as possible, especially if the application

requires fast, repetitive cycle operation.

If the above checks indicate that the proper

voltage and current is being supplied to the coil,

mechanical parts should be checked to assure

that they are in good operating condition and

properly installed. (See operating instruction under

Check No. 1).

Wear Pattern

NEW

BURNISHED

WORN

Figure 4