KB Electronics KBAC-48 User Manual

Page 20

20

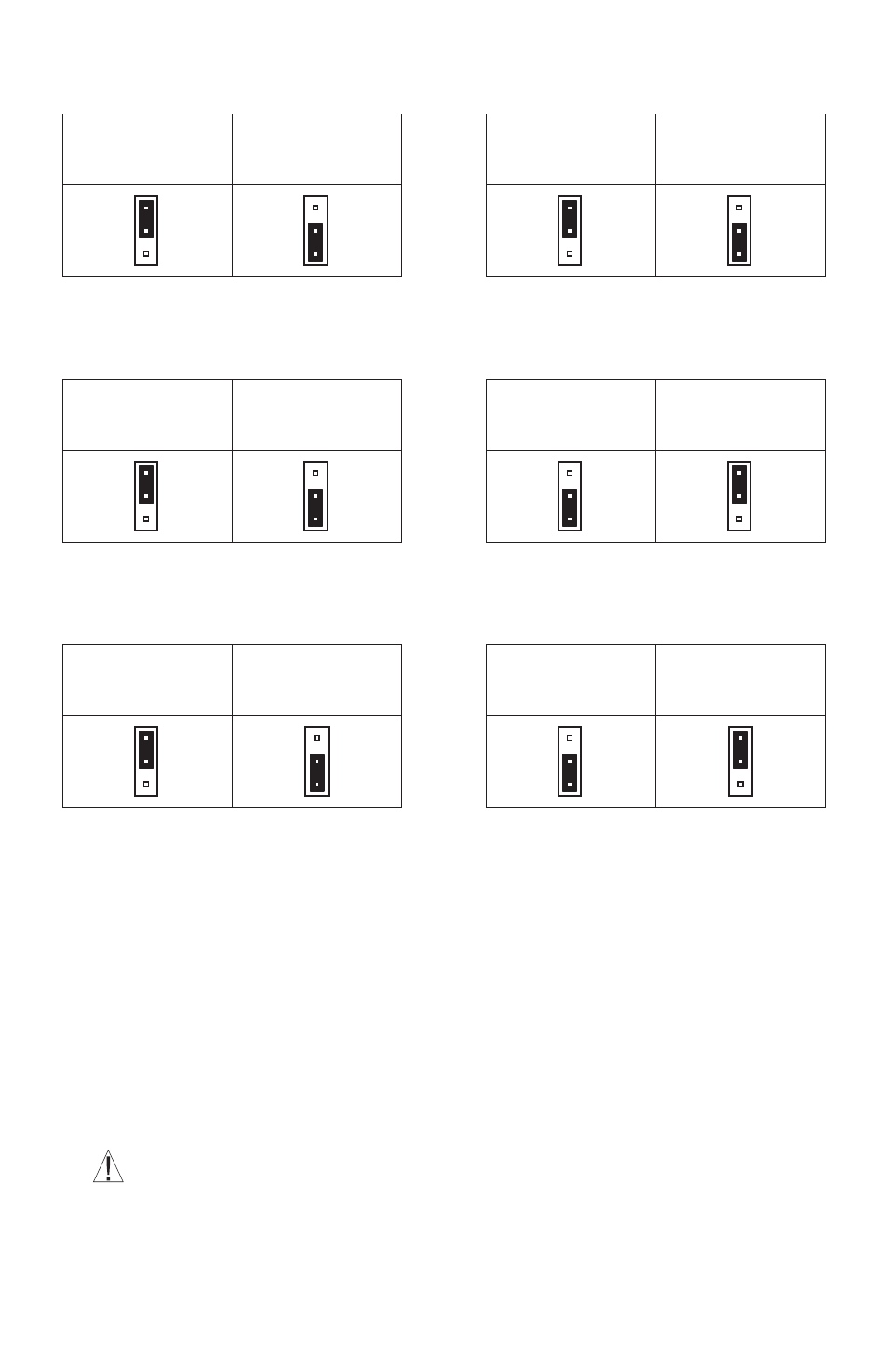

6.9 Torque Mode Selection (J10) – Jumper J10 is factory set to the “CT” position for Constant Torque

Mode, which is desirable for most machine applications. For Variable Torque Mode, used for HVAC

and fan applications, set Jumper J10 to the “VT” position. See Figure 27.

6.10 I

2

t Overload Selection (J11) – Jumper J11 is factory set to the “1” position for Inverter Duty Rated

Motors. For Non Inverter Duty Rated Motors and HVAC applications, set Jumper J11 to the “2”

position. See Figure 28. Also see Section 13.7 on page 25.

7 MOUNTING INSTRUCTIONS

It is recommended that the drive be mounted vertically on a flat surface with adequate ventilation.

Leave enough room below the drive to allow for AC line, motor connections, and any other wiring that is

required. Although the drive is designed for outdoor and washdown use, care should be taken to avoid

extreme hazardous locations where physical damage can occur. When mounting the drive in an enclosure,

the enclosure should be large enough to allow for proper heat dissipation so that the ambient tempera-

ture does not exceed 40 °C (104 °F) at full rating. See Figure 3 on page 11 and Figure 4 on page 12.

WARNING! Do not use this drive in an explosion-proof application.

Fixed Boost

(Factory Setting)

(J6 Installed in “FIX” Position)

Adjustable Boost

(J6 Installed in “ADJ” Position)

ADJ

J6

FIX

ADJ

J6

FIX

Figure 23 – Fixed

or Adjustable Boost Selection

Regenerative Braking

(Factory Setting)

(J7 Installed in “RG” Position)

DC Injection Braking

(J7 Installed in “INJ” Position)

INJ

J7

RG

INJ

J7

RG

INJ

J7

RG

Figure 24 – Regenerative

or DC Injection Braking Selection

Regenerative Braking

(Factory Setting)

(J7 Installed in “RG” Position)

DC Injection Braking

(J7 Installed in “INJ” Position)

F

J8

R

F

J8

R

Figure 25 – “Run” or “Fault”

Output Relay Operation Selection

Normally Open Stop Contact

(Factory Setting)

(J9 Installed in “NO” Position)

Normally Closed Stop Contact

(J9 Installed in “NC” Position)

NO

J9

NC

NO

J9

NC

Figure 26 – Normally Open

or Closed Stop Contact Selection

Constant Torque

(Factory Setting)

(J10 Installed in “CT” Position)

Variable Torque

(J10 Installed in “VT” Position)

VT

J10

CT

J10

CT

VT

Figure 27 – Constant or Variable

Torque Selection

Inverter Duty Rated Motor

(Factory Setting)

(J11 Installed in “1” Position)

Non Inverter Duty Rated

Motor Operation

(J11 Installed in “2” Position)

1

J11

2

J11

2

1

Figure 28

I

2

t Overload Selection