Figure 14 – enable circuit connection – KB Electronics KBAC-48 User Manual

Page 17

17

5.7 Voltage Following Connection –

An isolated* 0 – 5 Volt DC analog

signal input can also be used to

control motor speed in lieu of the

Main Speed Potentiometer. The

drive output will linearly follow

the analog signal input. Wire the

signal input positive lead (+) to

Terminal “P2” and the negative

lead (-) to Terminal “P1”. With

external circuitry, a 0 – 10 Volt DC

analog signal can also be used.

See Figure 13.

*If a non-isolated signal is used,

install the SIAC Signal Isolator

(Part No. 9600). The SIAC accepts

voltage (0 to ±2.5 thru 0 to ±25 Volts DC) or current

(4 – 20 mA DC) signal inputs. See Table 2 on page 8.

See Appendix A on page 27 for SIAC information.

Note: For signal following operation, the Minimum

Speed Trimpot (MIN) must be set fully counterclockwise.

WARNING! The signal input must be isolated

from the AC line. Earth grounding signal wir-

ing will damage the drive and void the warranty.

It is highly recommended that the SIAC Signal

Isolator (Part No. 9600) be installed when using

signal following.

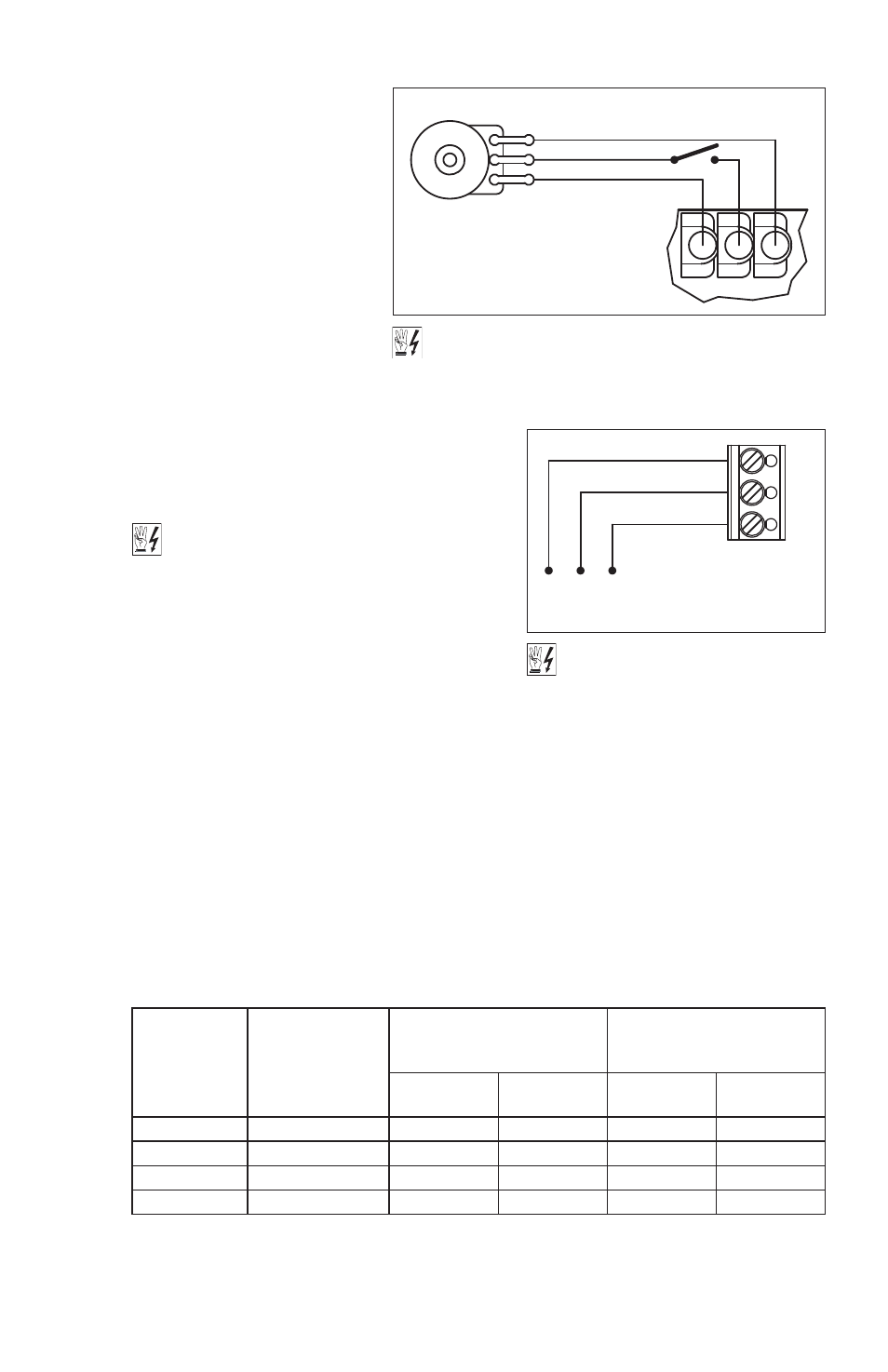

5.8 Enable Circuit Connection – The drive can also be

started and stopped with an Enable circuit (close to

run, open to stop). See Figure 14.

The Enable function is established by wiring a switch or contact in series with the orange Main

Speed Potentiometer lead which connects to Terminal “P2”. When the Enable Switch is closed, the

motor will accelerate to the Main Speed Potentiometer setting. When the Enable Switch is opened,

the motor will decelerate to stop.

WARNING! If the Enable Switch is to be mounted remotely, it is highly recommended that the

SIAC Signal Isolator (Part No. 9600) be installed.

5.9 Run/Fault Relay Connection – The Run/Fault Relay Output Contacts are located at TB2 and can

be used to turn equipment on or off, to signal a warning if the drive is put into the Stop Mode, or a

fault has occurred. See Figure 15.

The Run/Fault Relay Contact status for various drive operating conditions is shown in Table 6.

Table 6 – Drive Operating Condition and Run/Fault Relay Contact Status

Drive

Operating

Condition

Description

Run Relay Operation

(Jumper J8 Installed in “R” Position)

(Factory Setting)

Fault Relay Operation

(Jumper J8 Installed in “F” Position)

Normally

Open Contact

Normally

Closed Contact

Normally

Open Contact

Normally

Closed Contact

Power Off

Main Power Disconnected

Open

Closed

Open

Closed

Run Mode*

Normal Drive Operation

Closed

Open

Closed

Open

Stop Mode*

Selected by Operator

Open

Closed

Closed

Open

Fault**

Drive Tripped

Open

Closed

Open

Closed

*Run Mode or Stop Mode is selected using the Start/Stop Switch. **Overload, I

2

t, Short Circuit, Undervoltage and Overvoltage.

HIGH VOLTAGE! See Warning on Page 14.

Main Speed

Potentiometer

Enable Switch or Relay

Orange (Wiper)

Violet (High)

White (Low)

(Close to Run)

P1

P2

P3

Figure 14 – Enable Circuit Connection

HIGH VOLTAGE!

See Warning on Page 14.

Output Contacts

Run/Fault Relay

Normally Closed

Relay Common

Normally Open

NC

NO

TB2

CO

M

Figure 15 – Run/Fault Relay Output

Contacts Connection