Figure 5 – maximum allowed motor torque vs. speed – KB Electronics KBAC-48 User Manual

Page 13

13

4 IMPORTANT APPLICATION INFORMATION

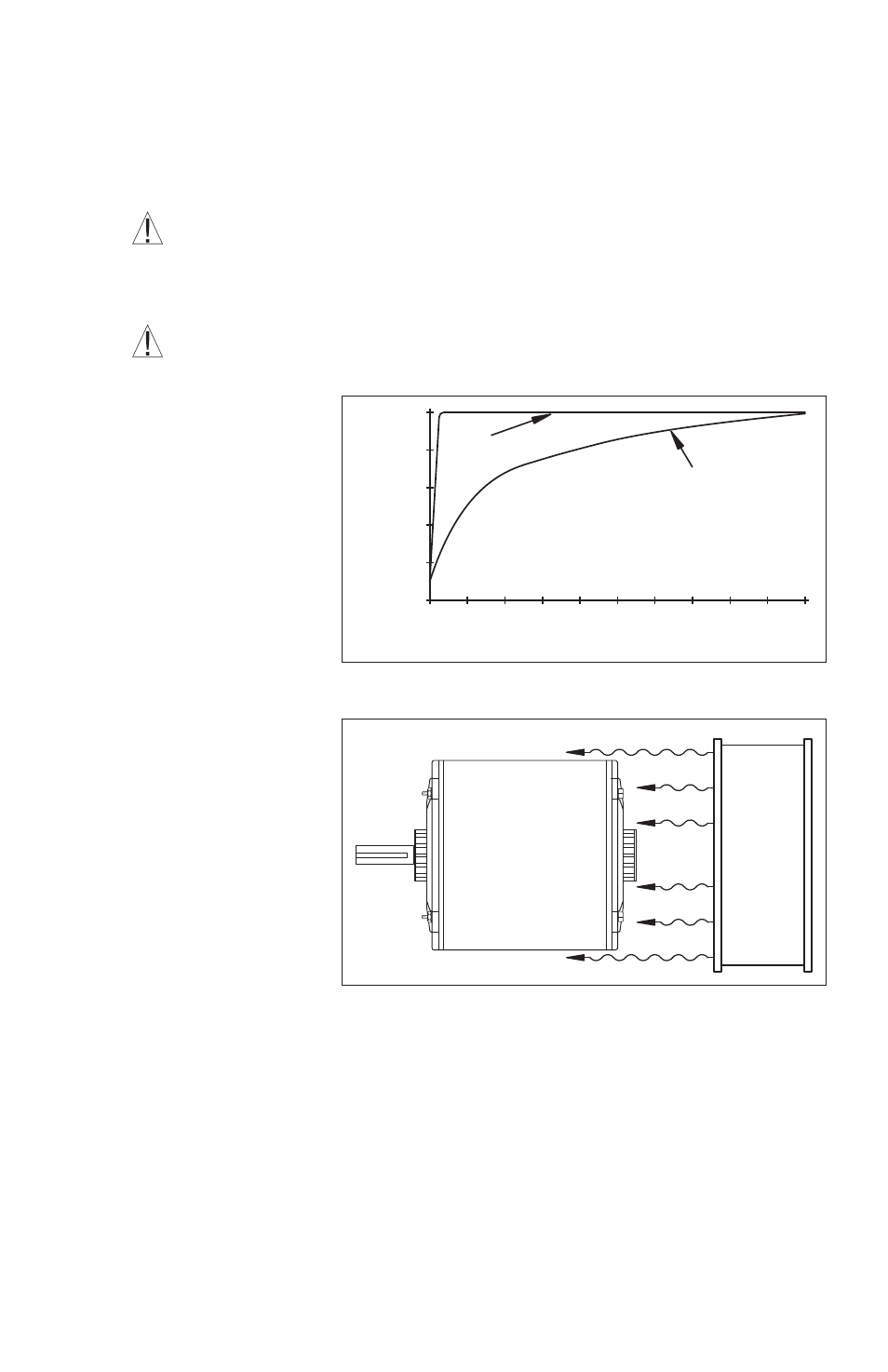

4.1 Motor With External Fan Cooling – Most totally enclosed fan-cooled (TEFC) and open ventilated

3-phase AC induction motors will overheat if used beyond a limited speed range at full torque.

Therefore, it is necessary to reduce motor load as speed is decreased.

Note: Some fan-cooled motors can be used over a wider speed range. Consult the motor manufacturer

for details.

WARNING! Some motors have low speed characteristics which cause overheating and

winding failure under light load or no load conditions. If the motor is operated in this manner

for an extended period of time, it is recommended that the unloaded motor current be checked

from 2 – 15 Hz (60 – 450 RPM) to ensure motor current does not exceed the nameplate rating.

Do not use motor if the motor current exceeds the nameplate rating.

It is recommended that the drive be used with Inverter Duty or TENV motors.

Inverter duty and most to-

tally enclosed non-ventilated

(TENV) motors can provide

full rated torque over an ex-

tended speed range without

overheating. See Figure 5.

If external fan cooling is

provided, open ventilated

motors can also achieve an

extended speed range at full

rated torque. A box fan or

blower with a minimum of

100 CFM per HP is recom-

mended. Mount the fan or

blower so the motor is sur-

rounded by the airflow. See

Figure 6.

4.2 Electronic Motor Overload

Protection – The drive con-

tains Modified I

2

t Overload

Protection.* Part of this

function consists of a Current

Limit (CL) circuit, which limits

the drive current to a factory

preset level of 160% of the

rated drive current. The CL

Trimpot is used to recalibrate

the drive current from 60%

thru 200%. The Power Start™

circuit provides an overshoot

function that allows most motors to develop more than 200% of starting torque and breakdown

torque.

Standard I

2

t is undesirable because it causes nuisance tripping. It allows a very high motor current

to develop and will turn the drive off after a short period of time. KB’s RMS Current Limit Circuit

avoids this nuisance tripping while providing maximum motor protection.

If the motor is overloaded to 120% of full load (75% of the CL setting), the I

2

t Timer starts. If the

motor continues to be overloaded at the 120% level, the timer will shut down the drive after 30

minutes. If the motor is overloaded to 160% of full load, the drive will trip in 6 seconds.

*UL approved as an overload protector for motors.

and TENV Motors

Inverter Duty

Maximum A

llow

ed

Mot

or T

orque

(%)

TEFC and Open Ventilated

Motors

Fan Cooled

100

60

70

80

50

30

40

10

0

20

90

Motor Speed (%)

40

0

20

60

80

100

Figure 5 – Maximum Allowed Motor Torque vs. Speed

Open Ventilated Motor

Fan or Blower

(100 CFM Min.

per HP)

Airflow

Figure 6 – Open Ventilated Motor with External Fan Cooling