Harrington Hoists and Cranes (N)ER Hoist - ((N)ER2) User Manual

Page 47

47

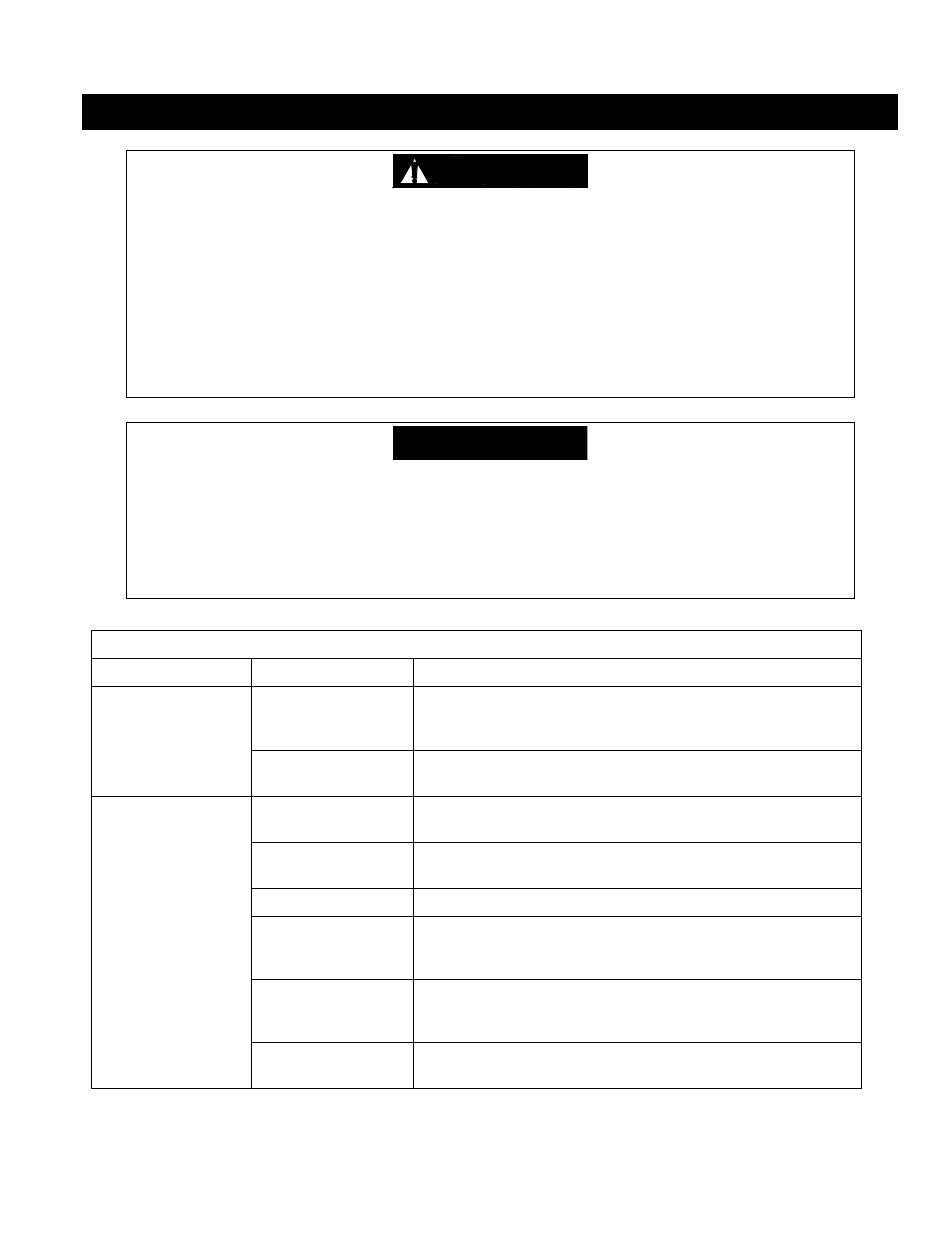

7.0 Troubleshooting

HAZARDOUS VOLTAGES ARE PRESENT IN THE HOIST AND IN CONNECTIONS BETWEEN

COMPONENTS.

Before performing ANY maintenance on the equipment, de-energize the supply of electricity to the

equipment, and lock and tag the supply device in the de-energized position. Refer to ANSI Z244.1,

“Personnel Protection – Lockout/Tagout of Energy Sources.”

To avoid a shock hazard, DO NOT perform ANY mechanical or electrical maintenance on the dual speed (or

VFD control) hoist within 5 minutes of de-energizing (disconnecting) the trolley or hoist. This time allows the

internal VFD capacitor to safely discharge.

Only trained and competent personnel should inspect and repair this equipment.

Do Not perform “withstand voltage” test or “insulation resistance” measurement (megger) with the VFD

connnected.

Do Not remove power to the hoist or trolley during operation.

Do Not connect power to the output of the VFD.

When handling VFD provide ESD protection.

Table 7-1 Troubleshooting Guide

Symptom

Cause

Remedy

Hoist moving in

wrong direction

Power supply

reversed phased

Switch 2 of the 3 power supply cord wires at the power source.

(Refer to Section 3.7.11 for instructions on how to check for

correct power supply phase connection.)

Improper electrical

connections

Refer to wiring diagram and check all connections.

Hoist will not operate

Loss of power

Check circuit breakers, switches, fuses, and connections on

power lines/cable.

Wrong voltage or

frequency

Check voltage and frequency of power supply against the rating

on the nameplate of the motor.

Hoist overloaded

Reduce load to within rated capacity of hoist.

Motor overheated

and thermal overload

protector has tripped

See Trouble Shooting Problem "Motor or brake overheating".

Improper, loose, or

broken wire in hoist

electrical system

Shut off power supply, check wiring connections on hoist control

panel and inside push-button pendant.

Brake does not

release

Check motor brake coil for continuity. Replace brake if needed.