Harrington Hoists and Cranes (N)ER Hoist - ((N)ER2) User Manual

Page 43

43

6.3.4

ER2 OIL LEVEL

– For hoists equipped with a Mechanical Load Brake/Friction Clutch, the oil level is

checked through the oil check hole at the top of the hoist. DO NOT remove the oil plug exposing the oil

level check hole on the side of the hoist. The oil level will be above the hole and will leak out. A dip

stick should be used to check the oil level through the top hole as shown in the in Figure 6-3 for ER2

hoists. Reference Table 6-5 for check distances from the top of the hoist body.

Table 6-5 ER (Mechanical Load brake Equipped) Gear Oil Check Distances

Capacity Code

Check Distance

(inches)

Check Distance

(millimeters)

001H, 003S

2.95

75

003H, 005L, 005S

3.94

100

010L, 010S, 020C

3.94

100

015S, 020L, 020S, 030C

4.72

120

025S, 030L, 050L

5.12

130

6.3.5

REPLACING OIL

– Change gear oil at least once every 5 years. The oil should be changed

more frequently depending on the hoist's usage and operating environment. Refer to Section 6.1.3.

Follow the procedure below for replacing the gearbox oil for your hoist:

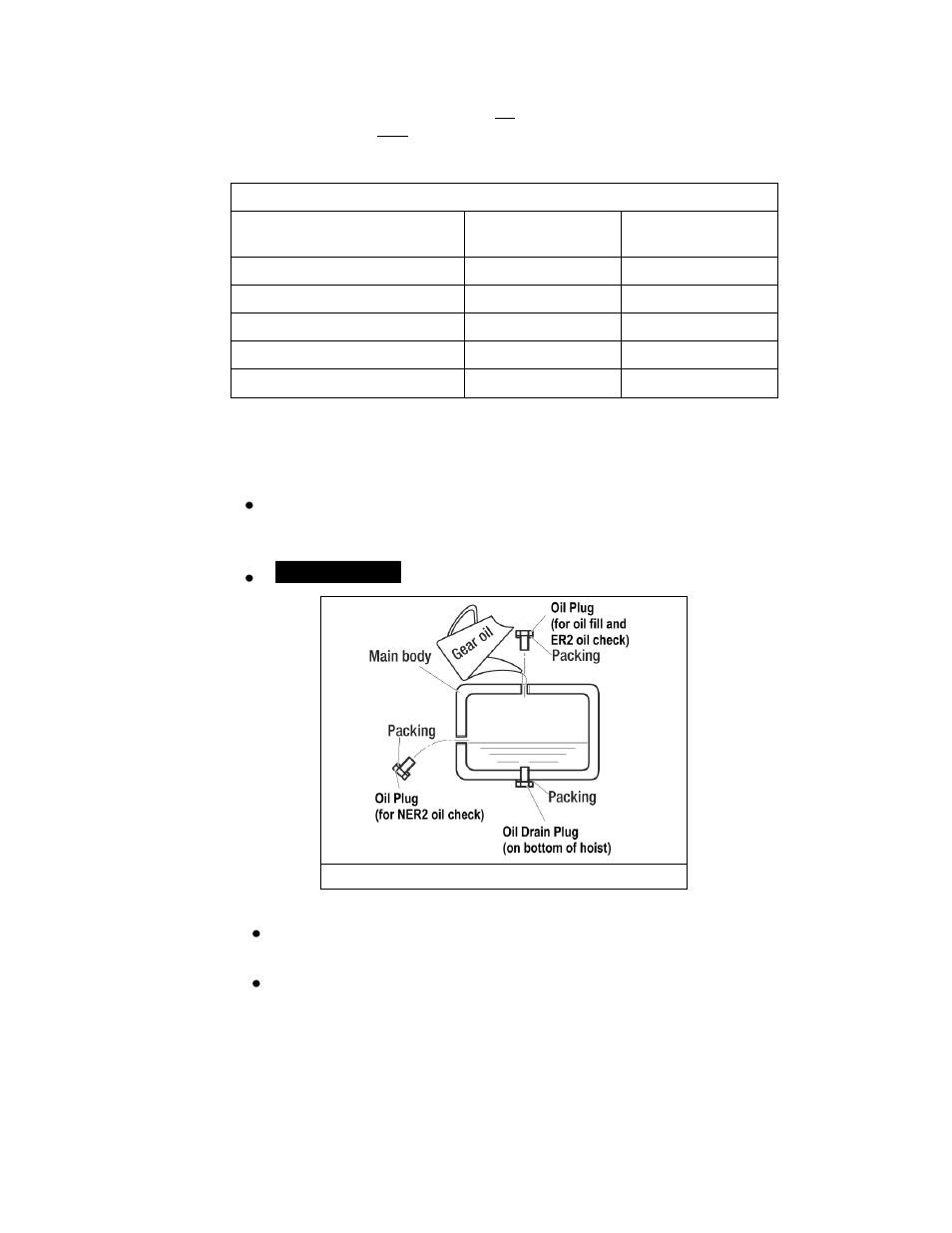

To drai

n the current oil from the hoist remove “Oil Plug” on top of the hoist and the “Oil Drain

plug” on the bottom of the hoist. Allow the old oil to drain completely. Refer to Figure 6-4 for oil

plug locations.

Dispose of the used oil in accordance with local regulations.

Figure 6-4 Oil Filling Diagram

Ensure that the oil plugs for the oil level check holes and the drain hole are reinstalled and

secured into the hoist body.

Refill the gear case with the correct quantity and type of new oil or until the oil level is within the

range shown in Table 6-6. Refer to Figure 6-4. Note that the NER2 & ER2 models have

different oil quantity requirements.