Harrington Hoists and Cranes (N)ER Hoist - ((N)ER2) User Manual

Page 33

33

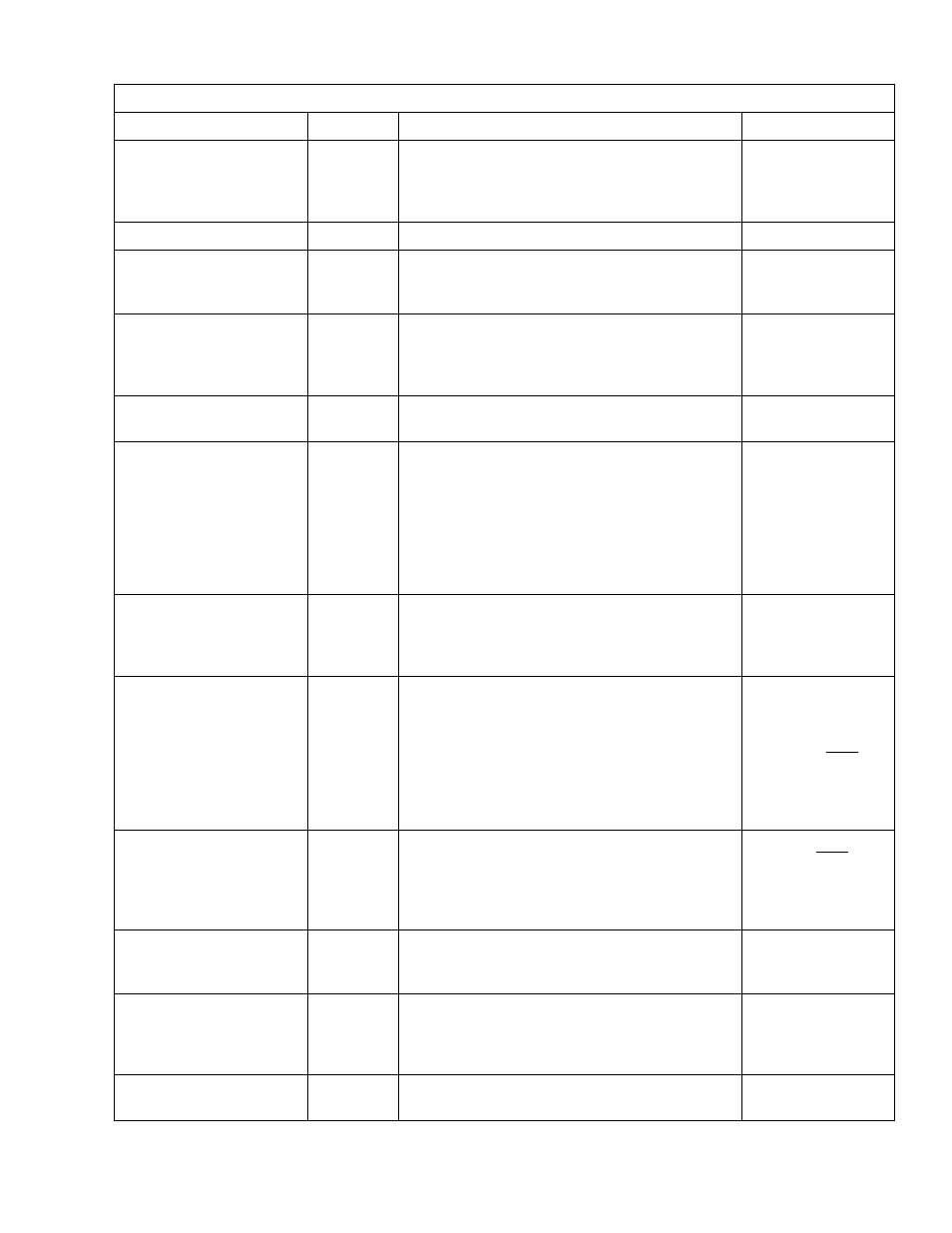

Table 5-3 Hoist Inspection Methods and Criteria

Item

Method

Criteria

Action

Load Chain

– Connection

Yoke Chain Pin (Double

Reeved Hoists Only)

Measure

The Connection Yoke Chain Pin should not have

and appare

nt deformation. The “d” dimension

should not be less than the discard value listed in

Table 5-6.

Replace.

Cushion Rubber

Visual

Should be free of significant deformation.

Replace.

Chain Springs

Visual

Chain springs should not be deformed or

compressed. Refer to Table 5-9 for Chain Spring

dimensions.

Replace.

Chain Guide

Visual

Chain Guide should be free of significant wear.

Chain Guide surfaces should be free of

deformation by nicks, gouges, and abrasion.

Refer to Figure 5-3.

Replace.

Chain Container (optional)

Visual

Container should not be damaged. Brackets

should not be deformed or missing.

Replace.

Housing and Mechanical

Components

Visual,

Auditory,

Vibration,

Function

Hoist components including load blocks,

suspension housing, chain attachments, clevises,

yokes, suspension bolts, shafts, gears, bearings,

pins and rollers should be free of cracks,

distortion, significant wear and corrosion.

Evidence of same can be detected visually or via

detection of unusual sounds or vibration during

operation.

Replace.

Bolts, Nuts and Rivets

Visual,

Check with

Proper

Tool

Bolts, nuts and rivets should not be loose.

Tighten or replace

as required.

Electromagnetic Brake

Assembly

Measure,

Visual

The electromagnetic motor brake gap is directly

related to brake disk wear. As the disk wears, the

brake gap will increase. The brake gap/wear

dimension should not be more than discard value

listed in Table 5-7. Bolts and screws should not

be loose.

Tighten bolts and

screws as required

or replace Brake

Assembly. Note:

DO NOT attempt to

adjust or dis-

assemble the Brake

Assembly.

Hub Joint

Visual

Hub Joint should have no apparent deformation

and abrasion. Must be fully seated. Refer to

Figure 5-4.

Replace. Note:

Electromagnetic

Brake Assembly

may also need to be

replaced.

V Ring

Visual

The V Ring should not be worn or show any

abnormality. It should be well lubricated. Refer to

Figure 5-5 and Section 6.1.7.

Clean/lubricate or

replace as required.

Contactor Contacts

Visual

Contacts should be free of significant pitting or

deterioration. On hoists equipped with

Count/Hour Meter check the contactor cycles

–

refer to Section 6.1.

Replace.

VFD (Dual Speed only)

Visual,

Function

There should be no fault codes (Reference

Section 3.6.)

Replace as needed.