Harrington Hoists and Cranes (N)ER Hoist - ((N)ER2) User Manual

Page 45

45

4)

Remove all chain components including the Bottom Hook Set Assembly, Stoppers, Cushion Rubbers,

Chain Springs, Striker Plates, Chain Pin and End Wire (or End Suspender) from the chain for reuse on

new chain. Inspect and replace any damaged or worn parts.

5)

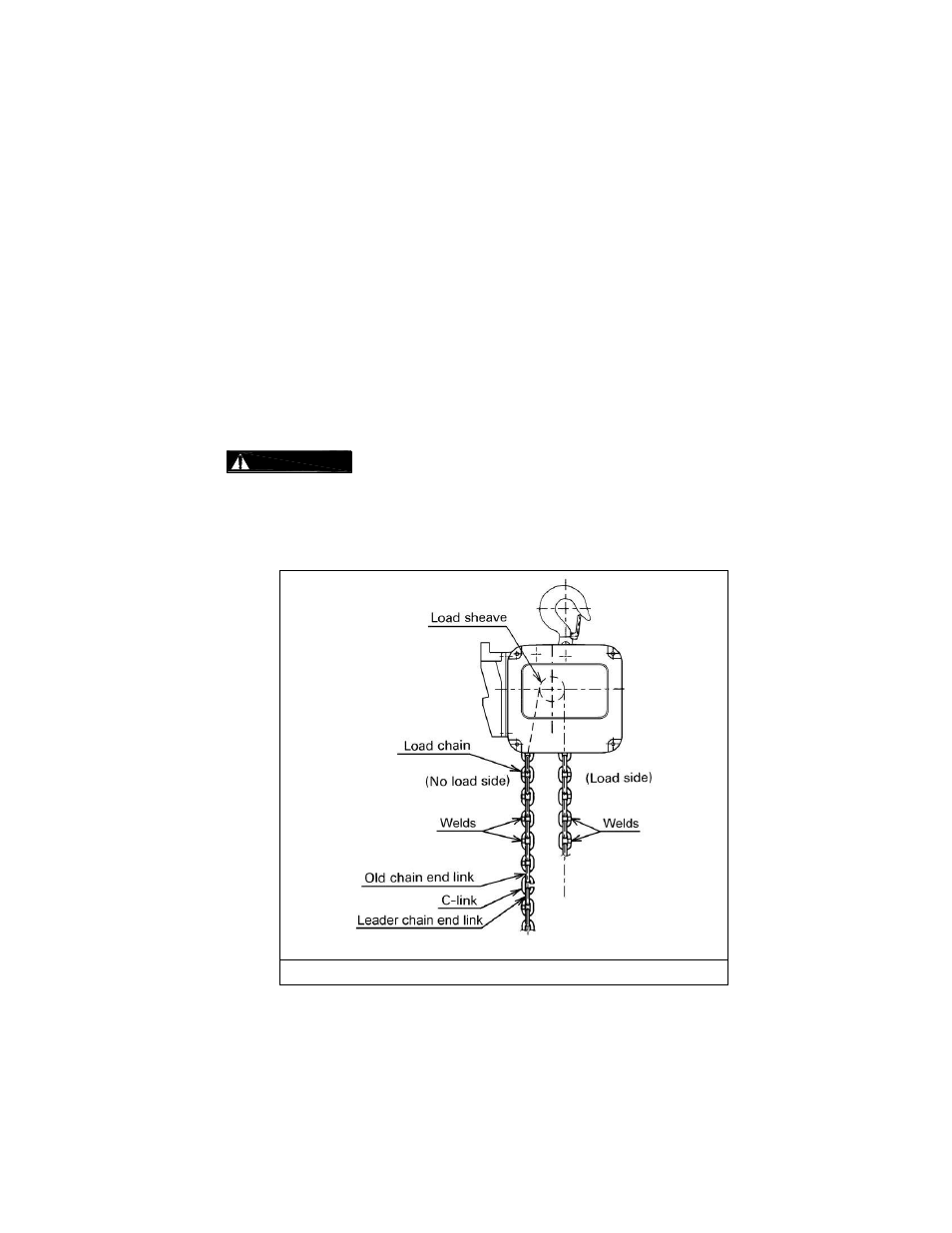

Using a C-link, attach the new chain to the end link of the old chain on the no-load side. The end link of

the new load chain should be connected so that the welded portions of the load chain's standing links

are oriented to the outside as they pass over the sheave. Refer to Figure 6-5.

6)

Operate the hoist down to move the chain though the hoist body. Stop when a sufficient amount of

new chain is accumulated on the load side.

7)

Single fall hoists - Attach the chain components (step 4 above) to the chain. Refer to Section 3.2 for

the proper locations.

8)

Double falls (020C, 030C, 050L) - Feed the end link on the load side of the new chain through the

required chain components (step 4 above) and the bottom hook’s Idle Sheave. Attach the remaining

chain components to the chain referring to Section 3.2 for the proper locations. Connect the end link to

the top connection yoke with the chain pin, slotted nut, and cotter pin. Ensure that chain remains free

of twists. Refer to Section 3.2.6.

9)

Make sure Stoppers, Cushion Rubbers, Chain Springs and Striker Plates are

properly installed. Refer to Section 3.2.

10)

After installation has been completed, perform steps outlined in Section 3.7, “Preoperational Checks

and Trial Operation".

Figure 6-5 Chain Replacement

6.6

Friction Clutch and Mechanical Load Brake with Friction Clutch

6.6.1

Friction Clutch (NER2 Models)

– If abnormal operation or slippage occurs do NOT attempt to

disassemble or adjust the Friction Clutch. Replace the worn or malfunctioning Friction Clutch as an

assembly with a new, factory adjusted part.