Harrington Hoists and Cranes LB Lever Hoist - (L5) User Manual

Page 47

47

Table 7-1 Troubleshooting Guide

Symptom

Cause

Remedy

Hoist will not lift

–

Lever will not operate

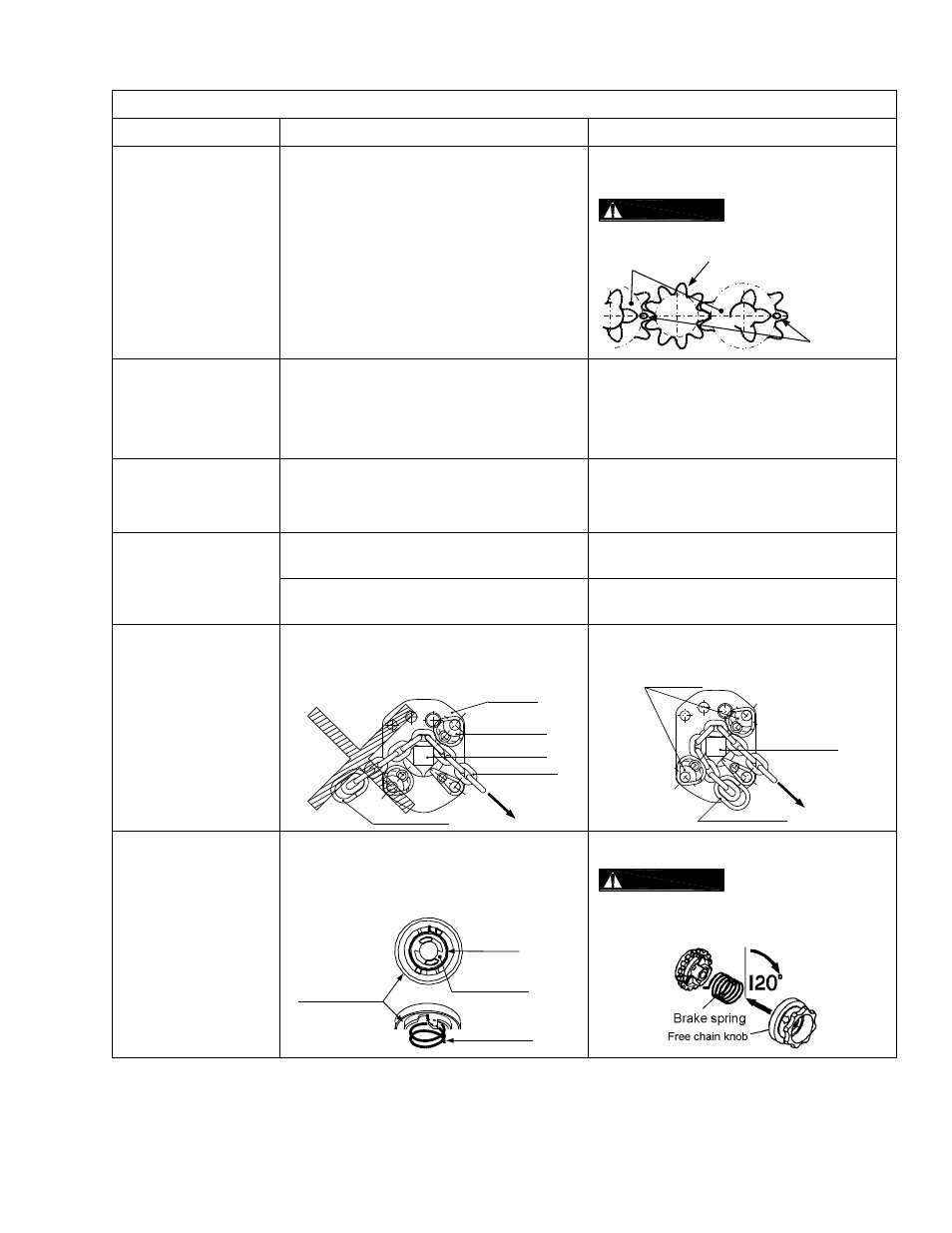

Gear #2 improperly timed

Reassemble gears properly and ensure

smooth operation before reuse.

Ensure the

„0‟ marks of

gear #2 are aligned properly, as shown.

Pinion

Gear #2

'0' Mark

Hoist with Slip Clutch

Hoist will not lift

–

Lever will operate but

load will not move.

Slip Clutch activated.

Reduce load to less than rated capacity.

Hoist with Slip Clutch

Hoist will not lift under

rated capacity.

Slip Clutch malfunction. Due to frequently

operating hoist with greater than rated load.

Replace friction clutch.

Do not frequently operate hoist with greater

than rated load.

Hoist will lift

intermittently

–

Slight or irregular

clicking

Poor pawl movement caused by faulty pawl

spring. The spring is loose or damaged.

Perform maintenance and/or repair.

Mis-assembly of pawl spring

Reassemble it properly and ensure to check

click sound of the pawl before reuse.

During operation, hoist

idles or load drifts

Poor contact of load sheave and load chain

caused by improper chain-reeving (see

picture)

Frame A

Chain guide

To bottom

hook

Load sheave

Chain stopper link

Load chain

Reassemble properly and ensure proper

lifting before reuse.

To bottom

hook

Chain guide

Load sheave

Chain stopper link

Hoist will not lift without

load

Mis-assembly of brake spring

Insufficient angle to set the spring will cause

a poor braking.

Brake spring

Slot for spring

Back of free chain

knob assembly

Slot for cam guide

Reassemble properly.

Turn the free chain

knob 120° clockwise and set the brake

spring.