0 maintenance and handling 6.1 lubrication – Harrington Hoists and Cranes LB Lever Hoist - (L5) User Manual

Page 33

33

6.0 Maintenance and Handling

6.1

Lubrication

6.1.1

Load Chain

Model L4 and Model L5 chain is not interchangeable.

For longer life, the load chain should be lubricated.

The load chain lubrication should be accomplished after cleaning the load chain with an acid free

cleaning solution.

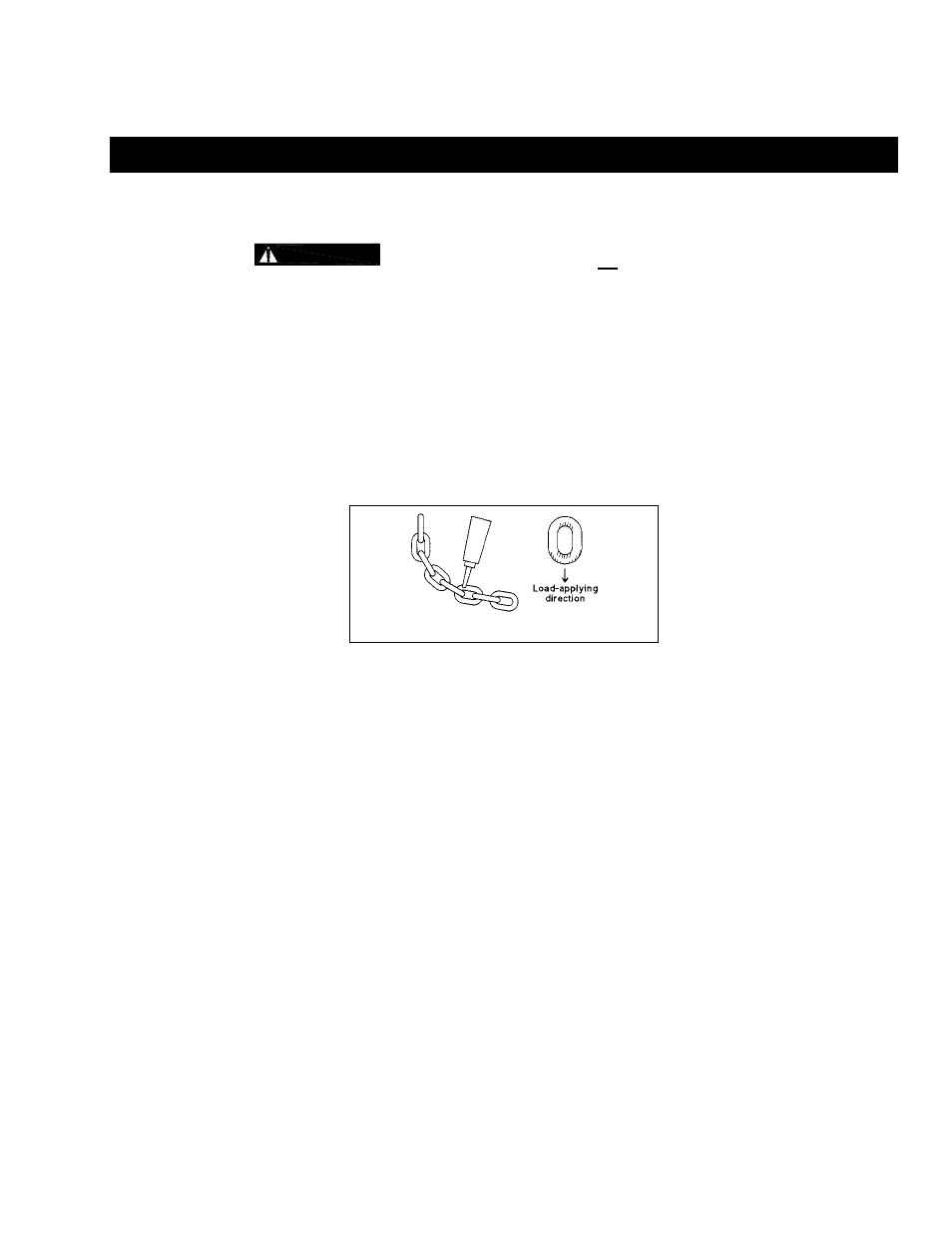

Apply Harrington lubricating grease (Part No. ER1BS1951) or an equivalent to industrial general

lithium grease, NLGI No. 0, to the bearing surfaces of the load chain links as indicated by the

shaded areas in Figure 6-1. Also apply the grease to the areas of the load chain (shaded areas in

Figure 6-1) that contact the load sheave. Insure that the grease is applied to the contact areas in

the load sheave pockets.

Machine or gear oil (grade ISO VG 46 or 68 oil or equivalent) may be used as an alternative

lubricant but must be applied more frequently.

Figure 6-1 Chain Grease Application

The chain should be lubricated every 3 months (more frequently for heavier usage or severe

conditions).

For dusty environments, it is acceptable to substitute a dry lubricant.

6.1.2

Hooks and Suspension Components:

Hooks

– Bearings should be cleaned and lubricated at least once per year for normal usage.

Clean and lubricate more frequently for heavier usage or severe conditions.

Hook Yokes and Latches

– Lubricate the hook yokes and hook latches at least twice per year for

normal usage; more frequently for heavier usage or severe conditions.

Suspension Pins - Lubricate the chain pin and the top pin at least twice per year for normal usage;

more frequently for heavier usage or severe conditions.