Harrington Hoists and Cranes LB Lever Hoist - (L5) User Manual

Page 34

34

6.2

Disassembly, Assembly and Adjustment

6.2.1

1) Perform proper disassembly or assembly in accordance with this manual.

2) The hoist utilizes dry friction plates; they are not to be lubricated.

3) Do not extend the load chain.

4) Remove old grease on the disassembled parts.

5) Replace components with Harrington Hoist approved parts.

6) To reassemble, apply new grease, and use a new split pin and snap ring.

Note: The following symbols in this manual indicate the recommended lubricants.

G1: NLGI No. 2

G2: Turbine Oil

G3: NLGI No. 1

6.2.2

Tools

– The following tools are required to disassemble/reassemble the hoist.

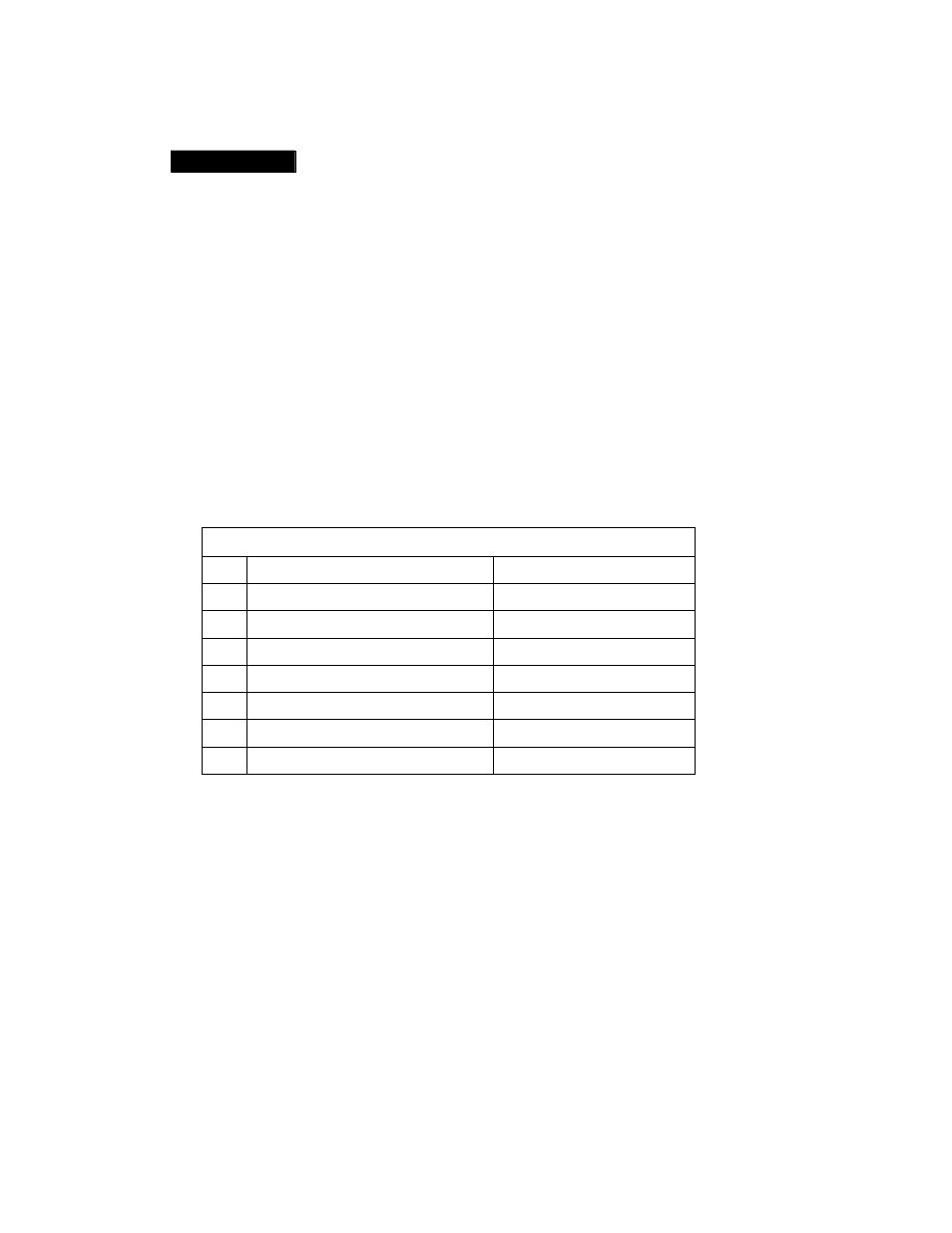

Table 6-1 Tools Required for Hoist Disassembly

No.

Tool

Operation

1

Snap ring pliers

Opening a snap ring

2

Socket wrenches: 12, 14 mm

Slotted nuts

3

Hex keys: 4, 5, 10, 12 mm

Socket head cap screws

4

Wrenches: 10, 12, 13, 14, 17 mm

Bolts and nuts

5

Phillips screwdriver

Machine screws

6

Pliers

Split pins

7

Soft-face (plastic) hammer

6.3

Hoist Disassembly

Proceed as follows:

6.3.1

Free Chain Knob

1) Pull out (50) Split Pin and remove (49) Slotted Nut.

2) Remove (48) Spring Holder, (47) Free Chain Spring, (45) Free Chain Knob assembly, (43) Brake

Spring and (44) Cam Guide from (16) Pinion.