Ransburg, Micropak - operation, Canbus address – Ransburg MicroPak LECU5004 User Manual

Page 18: Di/dt operating mode, Micropak di/dt sensitivity levels

MicroPak - Operation

Ransburg

15

LN-9218-00.13

CANBus Address

The MicroPak must be set at a non-zero CANBus

address when CANBus communication is used,

whether from an outside CANBus source, Discrete

I/O Module or Node Adapter.

When front panel controls are used, SW3-3 can

be set to OFF so that the HV ON mode is always

enabled, meaning that anytime the HV Ready

mode is entered, HV is turned on. This allows

the front panel kV switch to enable the HV Ready

and HV On modes at the same time.

The address is set in binary by Switch SW7, la-

beled “Node Address”, positions 2-4 with position

4 being the LSB (see Figure 6). In applications

where Discrete I/O Module is used, the MicroPak

must be set at CANBus address 01. In Node

Adapter applications, the MicroPak(s) must be

set to a CANBus address corresponding to the

locations in the PLC I/O tables. Each MicroPak

must have a unique address from 01-04.

Di/dt Operating Mode

A di/dt (rate of change in current with respect to

time) safety overload function can be used in

addition to the fixed current overload. This is an

adjustable setting which determines the maximum

current increase that can occur during a fixed

time period.

The di/dt detection feature will improve the ability

of the power supply to prevent discharges to the

applicator when a grounded object is approaching

at rates greater than approximately 4 inches per

second. Slower rates of approach are typically

sensed by the fixed current overload if properly

set. The di/dt and fixed current overloads must

be set correctly to prevent discharges when using

metal (unlisted) applicators.

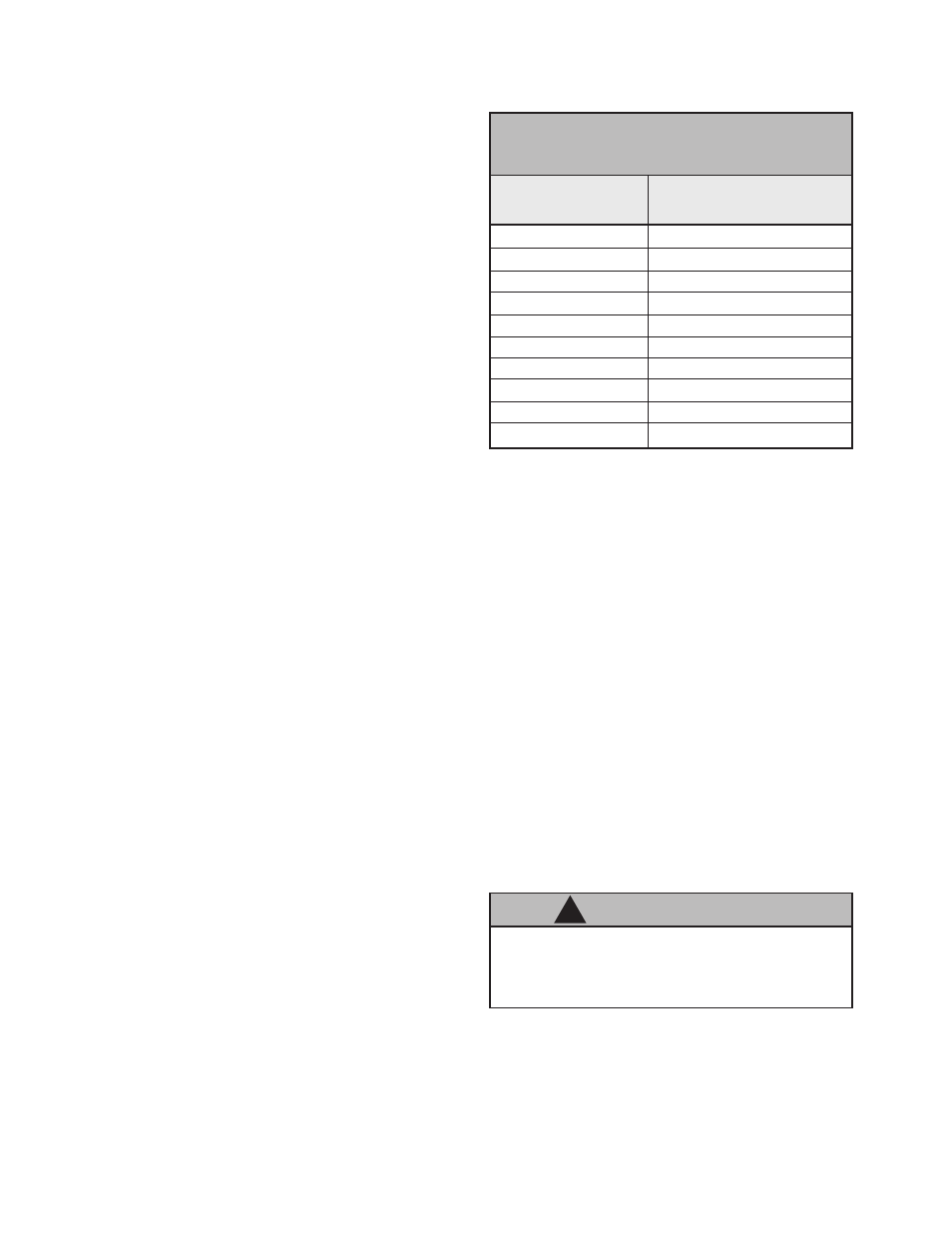

The MicroPak controller monitors the output

current and compares the value to the rate of

change set- point (SLP) provided by the user set-

ting. (See the “MicroPak Di/dt Sensitivity Chart”

for corresponding rates of change for each SLP

setting number.)

8.0

10.0

15.0

20.0

25.0

30.0

35.0

40.0

50.0

60.0

SLP #

Sensitivity

µA/100m Sec.

MICROPAK di/dt

SENSITIVITY LEVELS

0

1

2

3

4

5

6

7

8

9

Separate ground connections

MUST be

used for grounding the part and the Power

Supply.

The di/dt overload is disabled for the time required

to ramp voltage from a lower requested kV to a

higher value. This time will vary based on the

magnitude of the kV increase. The HV “ON” LED

will flash ON and OFF during each di/dt inhibit

period (Local mode only).

When the applicator is moved quickly (e.g., ro-

bot), SLP #7, #8 or #9 should be used to avoid

nuisance faults.

For di/dt modes of operation, the di/dt function is

enabled by setting SW7-6, located on the Micro-

Pak Process PCB to the ON (down position). For

all other applications where di/dt does not apply,

SW7-6 must be set to the OFF (up) position. This

is the default setting for all MicroPak control unit

models that do not have the di/dt function.

C A U T I O N

!