Ransburg, Troubleshooting guide, Aerbell 33 rotary atomizer - maintenance – Ransburg Aerobell 33 AER5000, AER5001 User Manual

Page 37

Aerbell 33 Rotary Atomizer - Maintenance

Ransburg

33

LN-9521-00.4

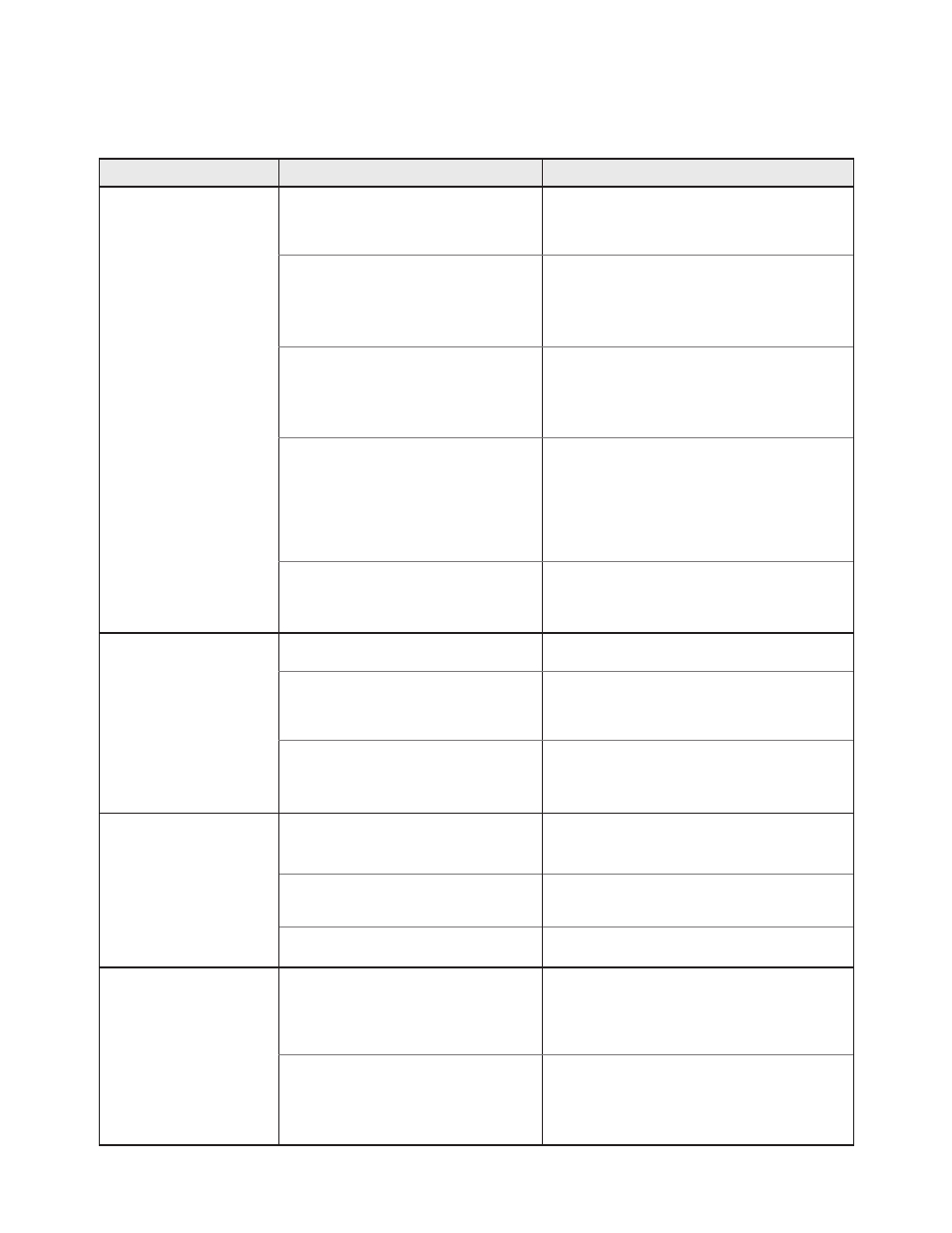

Low Transfer

Efficiency (or light

coverage)

No Turbine Air

Speed Feedback

Fault

No Fluid Flow

Low or no high voltage

Poor grounding of parts being

coated

Excessive turbine speed

Excessive shaping air

Excessive target distance

Turbine drive air not present

Bearing air return signal not

present

Brake air is activated

Damaged fiber-optic cable between

atomizer and control panel

Connection at the fiber-optic

transmitter is loose

Fiber-optic transmitter failure

Turbine is not rotating

Fluid regulator does not actuate

Verify high voltage at bell cup edge. Normally,

a high voltage setting of 100kV is appropriate

for most applications.

Verify that parts being coated are properly

grounded (the electrical resistance between

the part and ground must not exceed 1

megohm).

For optimum transfer efficiency and spray pat-

tern control, the bell rotational speed should

be set at the minimum required to achieve

proper atomization of the coating material.

Shaping air should be set at the minimum

volume required to gently direct the spray

pattern toward the part being coated. Exces-

sive shaping air will cause some atomized

particles to "blow-by" the part or bounce back

onto the atomizer.

The recommended target distance is between

8 and 12 inches (see "Target Distance" in the

"Operation" section of this manual).

Verify supply air pressure.

a. Verify bearing air return signal.

b. Increase bearing air supply pressure to 90

psig (±10 psig)

Remove brake air signal (turbine air and brake

air must be interlocked to prevent both from

being used simultaneously).

Repair or replace fiber-optic cable.

Re-install fiber-optic cable and tighten the

compression nut.

Replace fiber-optic transmitter.

Verify rotation of turbine (the paint valve air

pilot must be interlocked with the turbine speed

feedback signal to ensure that paint does not

flow into the air bearing).

a. Verify fluid supply.

b. Verify that air pilot signal is present.

Figure 15: Troubleshooting Guide (Continued)

TROUBLESHOOTING GUIDE

(Cont.)

General Problem

Possible Cause

Solution