Ransburg, Air filtration requirements, Aerbell 33 rotary atomizer - installation – Ransburg Aerobell 33 AER5000, AER5001 User Manual

Page 15

Aerbell 33 Rotary Atomizer - Installation

Ransburg

11

LN-9521-00.4

AIR FILTRATION REQUIREMENTS

Ransburg

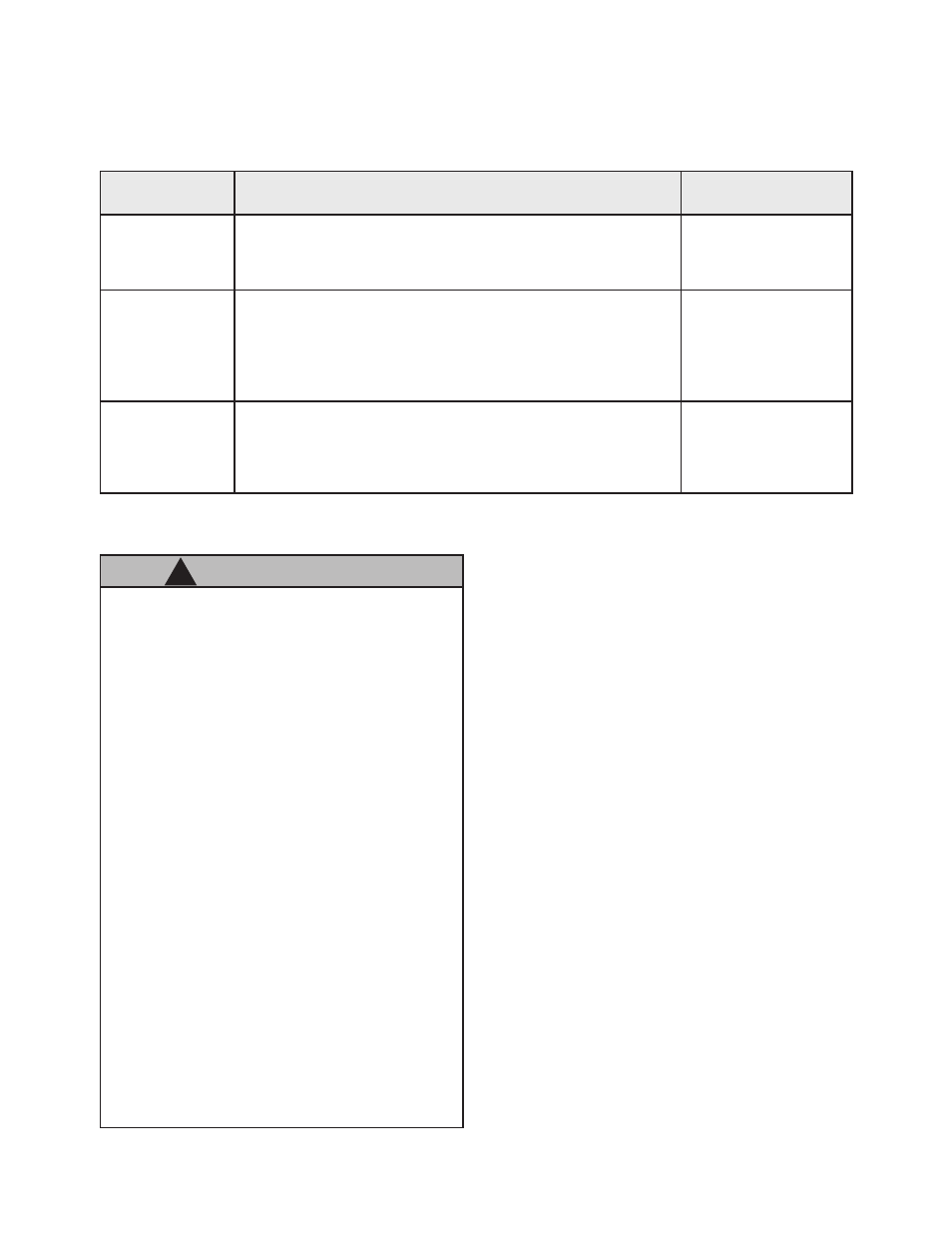

Filter Model No.

HAF-503

RPM-417

RPM-418

HAF-15 Element,

One

RPM-32 Elements,

Carton of 4

RPM-33 Elements,

Carton of 8

Pre-filter, removes coarse amounts of oil, moisture &

dirt. Used upstream of RPM-417 pre-filter (used in

systems with poor air quality).

Pre-filter, coalescing type, 136 scfm, 98.5% efficiency

particulate removal .3 to .6 micron, max. aerosol passed

1.0 micron, max. solid passed .4 micron (dependent

upon scfm requirement per applicator, one RPM-417

can be used with up to three Aerobell 33 assemblies).

Bearing air filter, coalescing type, 19 scfm, 99.995%

efficiency particulate removal .3 to .6 micron, max.

aerosol passed .6 micron, max. solid passed .2 micron

(one per applicator).

Description / Specifications

Replacement

Element Part No.

Figure 8: Recommended Air Filtration

Air must be properly filtered to ensure

extended turbine life and to prevent contam-

ination of the paint finish. Air which is not ad-

equately filtered will foul the turbine air bear-

ings and cause turbine failure. The correct

type of filters must be used in an Aerobell 33

system. The filter elements must be replaced

on a regular schedule to assure clean air.

It is the user’s responsibility to en-

sure clean air at all times. Turbine fail-

ure resulting from contaminated air will

not be covered under warranty. Figure 8

shows the pre-filter and bearing air filter(s)

which are recommended for use in Aerobell

33 systems. If other filters are incorporat-

ed in the system, the filters to be used must

have filtering capacities equal or better than

those shown in Figure 8.

The user must ensure the bearing air

supply is not inadvertently turned off while

the Aerobell 33 air motor is turning. This will

cause air bearing failure.

C A U T I O N

!