Ransburg, Bearing air adjustment, Shaping air – Ransburg Aerobell 33 AER5000, AER5001 User Manual

Page 22: Brake air

Aerbell 33 Rotary Atomizer - Operation

Ransburg

18

LN-9521-00.4

BEARING AIR

ADJUSTMENT

The nominal bearing air pressure is 90 psi,

measured at the rear of the atomizer. Minimum

pressure is 70 psi and maximum pressure is 100

psi. The turbine should never be operated with

less than 70 psi bearing air pressure.

Bearing air must be present when turning the

turbine on. Bearing air must remain on when

the turbine air is turned off until the turbine stops

spinning. Never turn off bearing air to cause the

turbine to stop spinning. If connected, brake air

can be used to slow the turbine.

The Aerobell 33 is equipped with a bearing air

return line to monitor bearing air pressure at the

turbine manifold. When connected to the re-mote

Atomizer speed controller, operation of the turbine

will automatically be shut down whenever the

bearing air pressure falls below 60 psi.

SHAPING AIR

Shaping air is used to shape the spray pattern.

Lower input pressure results in wider pattern size,

while higher input pressure reduces the pattern

size. Shaping air does not help atomize the ma-

terial, but will assist in the penetration of atomized

particles into cavity areas. Ideally, shaping air

should be kept at the minimum pressure which will

provide a proper finish for the fluid being sprayed.

Excessive shaping air will cause some atomized

particles to blow by the target, reducing the wrap

around effect at edges and corners. Excessive

shaping air may also cause some paint particles

to bounce back onto the atomizer, causing the

atomizer surface to become contaminated.

BRAKE AIR

Brake air is used to slow the turbine speed in a

minimum length of time. It is advantageous for

short cycle times during color change, or may be

used to reduce speed or stop the turbine. Never

operate brake air with the turbine air on. Approx-

imate brake times to reduce the turbine speed

are shown in Figure 13. These times are based

on 60 psi air pressure at the brake air connector.

The use of brake air is optional, and may not be

required for many installations. The Atomizer

Module control system provides the circuitry for

automatic use of the brake air.

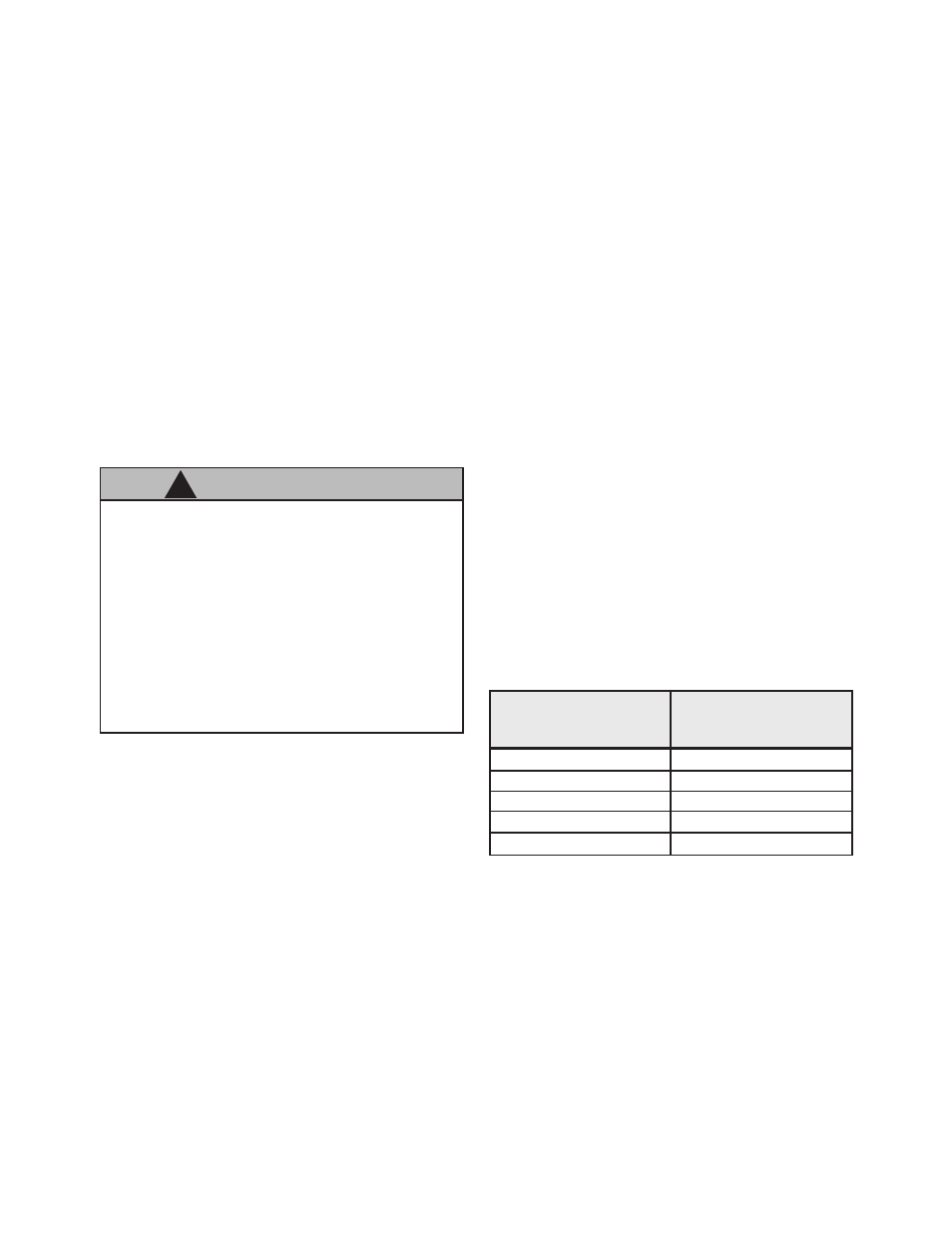

Figure 13: Braking Time

To Brake From (RPM)

50,000 to 40,000

50,000 to 20,000

50,000 to 0

40,000 to 20,000

40,000 to 0

Seconds

(Approx.)

3.7

7.5

10.0

4.0

9.0

Bearing air must be on whenever the

turbine is operated. If not, severe bearing

damage will occur. It is recommended that

bearing air be left turned on at all times, ex-

cept during maintenance or disassembly.

Bearing damage (and subsequent turbine

failure) caused by running the turbine with-

out bearing air will not be covered under the

Ransburg warranty.

C A U T I O N

!