Ransburg, Mounting, Fluid connections – Ransburg Aerobell 33 AER5000, AER5001 User Manual

Page 16: Speed monitor connections, Electrical connections, Aerbell 33 rotary atomizer - installation

Aerbell 33 Rotary Atomizer - Installation

Ransburg

12

LN-9521-00.4

MOUNTING

The Aerobell 33 incorporates its own insulator

mounting rod. The diameter at the rear is 1.9

inches, for mounting to a reciprocator, stationary

stand, or other means of support. The atomizer

assembly is mounted to this horizontal rod by a

3/4 inch insulating post, inserted into a swivel

clamp and secured by four plastic bolts. The

arrangement allows positioning of the front of the

turbine. Normally, the insulator support rod is po-

sitioned perpendicular to the conveyor path, with

the swivel providing for left or right adjustment of

the atomizer assembly. The swivel clamp plate

can be inverted to provide a locking mechanism

to hold the applicator in line with the insulator

support rod.

FLUID CONNECTIONS

The paint supply to the Aerobell 33 is connected

at the rear of the atomizer assembly to the regu-

lator. Solvent and dump line connections enter

the housing and are connected to the appropriate

valves. Ports are labeled with blue lettering.

ELECTRICAL CONNECTIONS

Electrical connections to the Aerobell 33 atomizer

assembly consist of only the high voltage cable.

This cable plugs into the resistor module fitting,

located at the rear of the assembly, which protrudes

through an opening in the rear bulkhead. After

inserting the cable entirely into the tube and feel-

ing the banana plug make contact on the inside,

tighten the cable compression fitting nut around

the high voltage cable with an appropriate wrench.

Reinstall the connector cover with plastic screw.

SPEED MONITOR

CONNECTIONS

A fiber-optic cable assembly connects the speed

signal output of the rotary atomizer assembly to

the Pulsetrak Speed Monitor/Control System or

Fotronics

TM**

Atomizer Module.

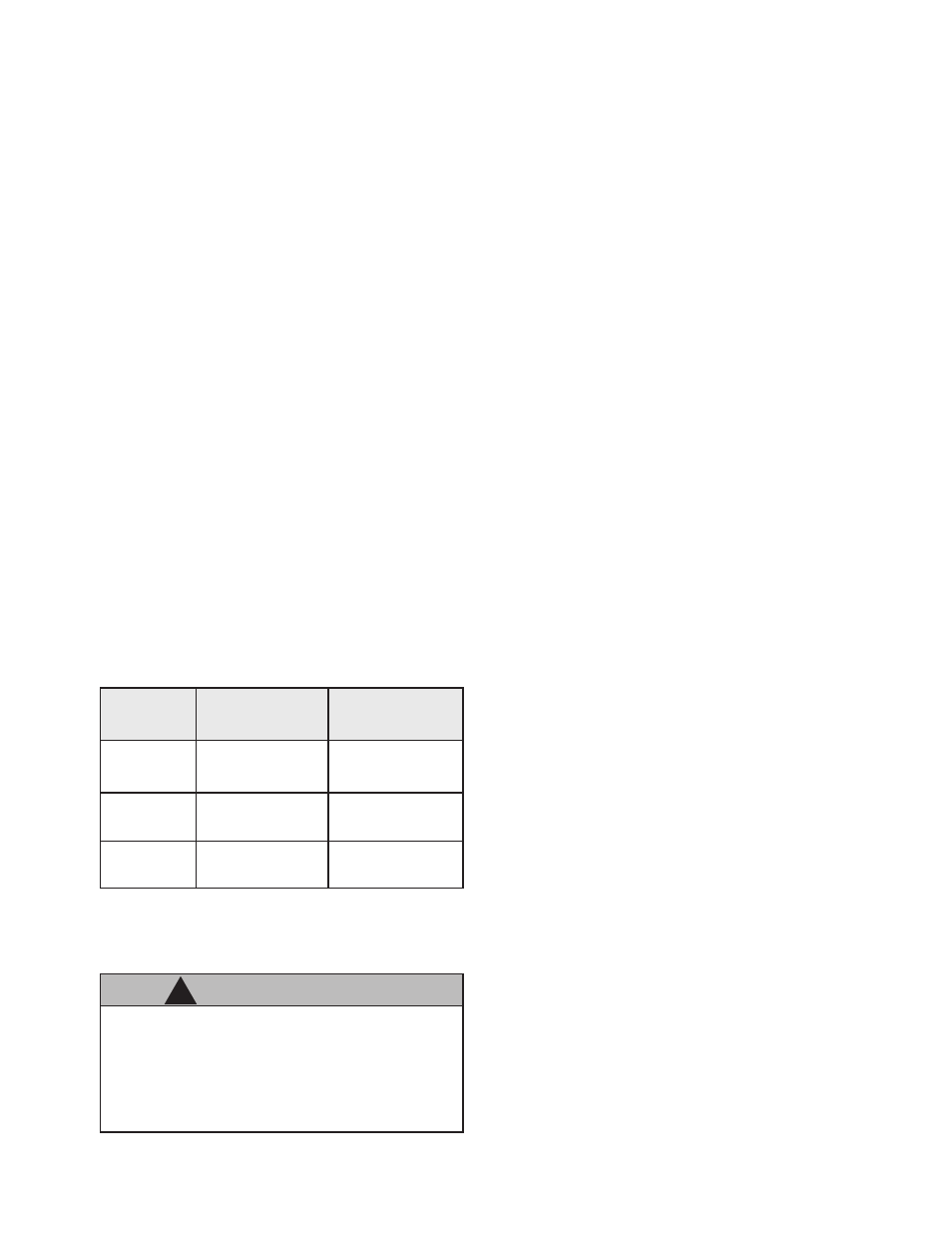

Figure 9: Fluid Tubing Connection Requirements

.156", .170", or

.188" I.D. PFA

.125" I.D.

PFA

.250" I.D.

PFA

Paint Line

(P.IN)

Solvent Line

(SOL)

Dump Line

(DUMP)

100 psig

(689 kPa)

30-60 psig

(207-413 kPa)

Variable

Fixed

Atomizer

Pressure

(nominal/max.)

The normal fluid flow range is 25-500 cc/

min. The maximum flow rate must not ex-

ceed 500 cc/min. to avoid solvent or paint

from flooding into the internal portion of the

air bearing motor assembly or front shroud.

C A U T I O N

!