Troubleshooting guide, Turbodisk applicator - maintenance – Ransburg Turbodisk Applicator Assembly A11376 User Manual

Page 28

Turbodisk Applicator - Maintenance

23

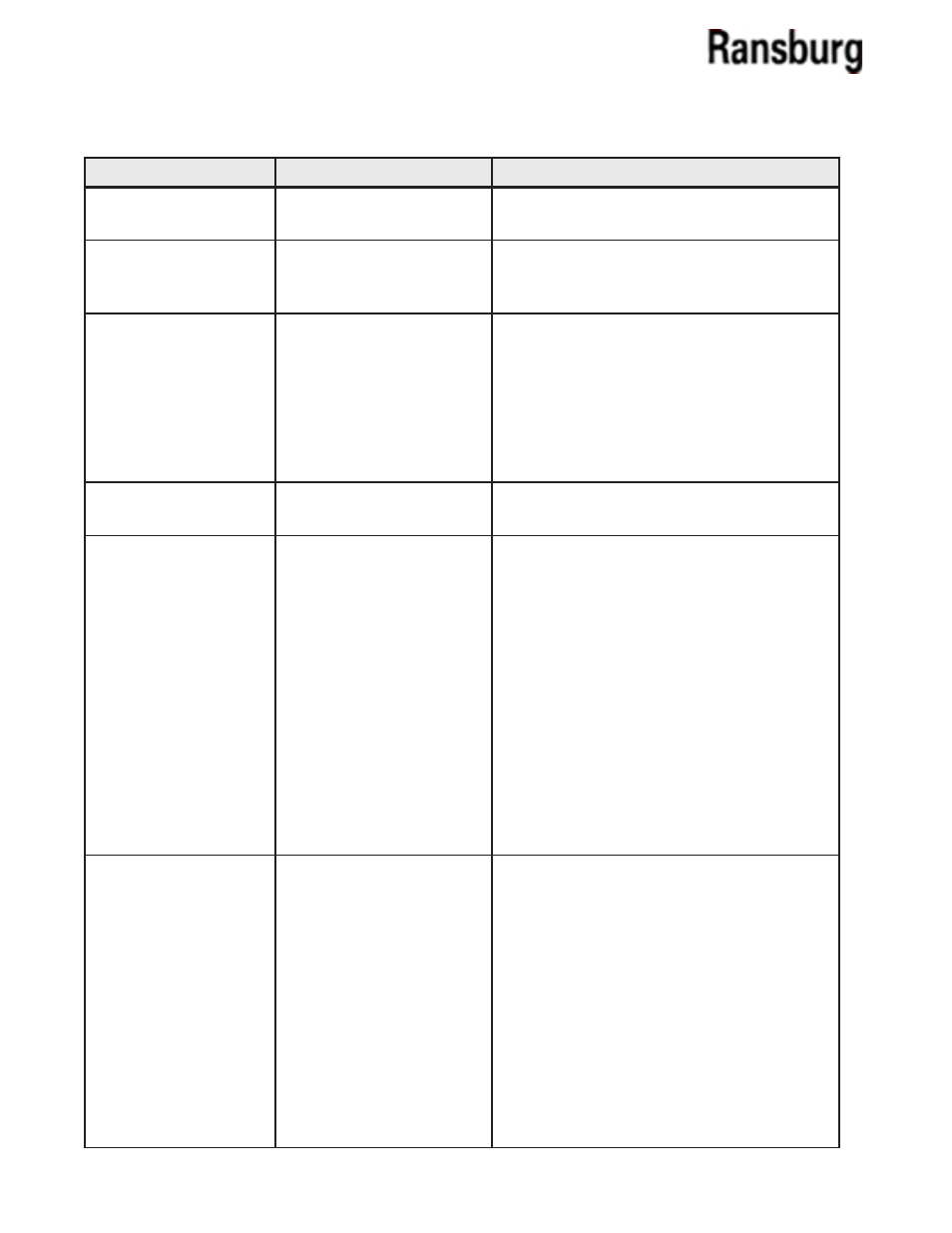

TROUBLESHOOTING GUIDE

General Problem

Cause

Solution

Fluctuating Pattern

1. Not enough back

pressure on regulator

1. Part hangers, hooks, are

not clean

1. Low voltage

2. Disk RPM to high

3. Booth flow to high

4. Disk edge to part

distance to great

1. Dirty high voltage contacts

1. Target distance to close

2. Conductive paint

3. Fairing dirty

4. High voltage cable break-

down

5. Fluid tube pinholed to

ground on conductive

paint

systems

6. Isolation mounting rod

dirty or carbon tracked

1. Power supply

2. Faulty high voltage switch

or junction tank

3. High voltage cable

1. See regulator manual for diagnosis.

1. a. Clean hangers.

b. Check ground continuity. (Must be less

than 1 Megohm.)

1. Check disk voltage with high voltage probe.

2. Slow disk speed.

3. Reduce booth air flow.

4. Decrease conveyor loop diameter.

1. Clean and/or replace.

1. Check target distance. Ideal target distance is

12-inches minimum.

2. Solventbase paint conductivity should be

between .05 and 20 megohms on Ransburg

Paint Test Meter.

3. Clean with nonpolar solvent.

4. Replace cable.

5. Check tubing routing for areas where fluid tube

comes near a ground.

6. Clean with nonpolar solvent or replace.

Use the following procedure to isolate problem:

- Verify power supply output. Refer to power

supply manual for procedure.

- Remove the fairing and measure input voltage

to

the rotator assembly by removing the high

voltage

cable from the connector fitting and inserting it

into the high voltage probe. If voltage is low,

replace high voltage cable with a known good

one and retest.

- If voltage is still low, check for bad connections

in the high voltage Junction or Switch Tank.

Refer to procedures in the proper manual.

- Reinstall the high voltage cable. Check voltage

at the rotator housing.

Light Coverage on Some

Parts

Poor Transfer Efficiency

Low Current Readings

High Current Readings /

Power Supply Overloads

Low Voltage

AA-07-02.1