Operation, The fulton companies 2013, Water header honeywell header sensor and well – Fulton Pulse HW (PHW) Fully Condensing Hydronic Boiler User Manual

Page 58

© The Fulton Companies 2013

OPERATION

PHW-IOM-2013-0214

SECTION 3

3-22

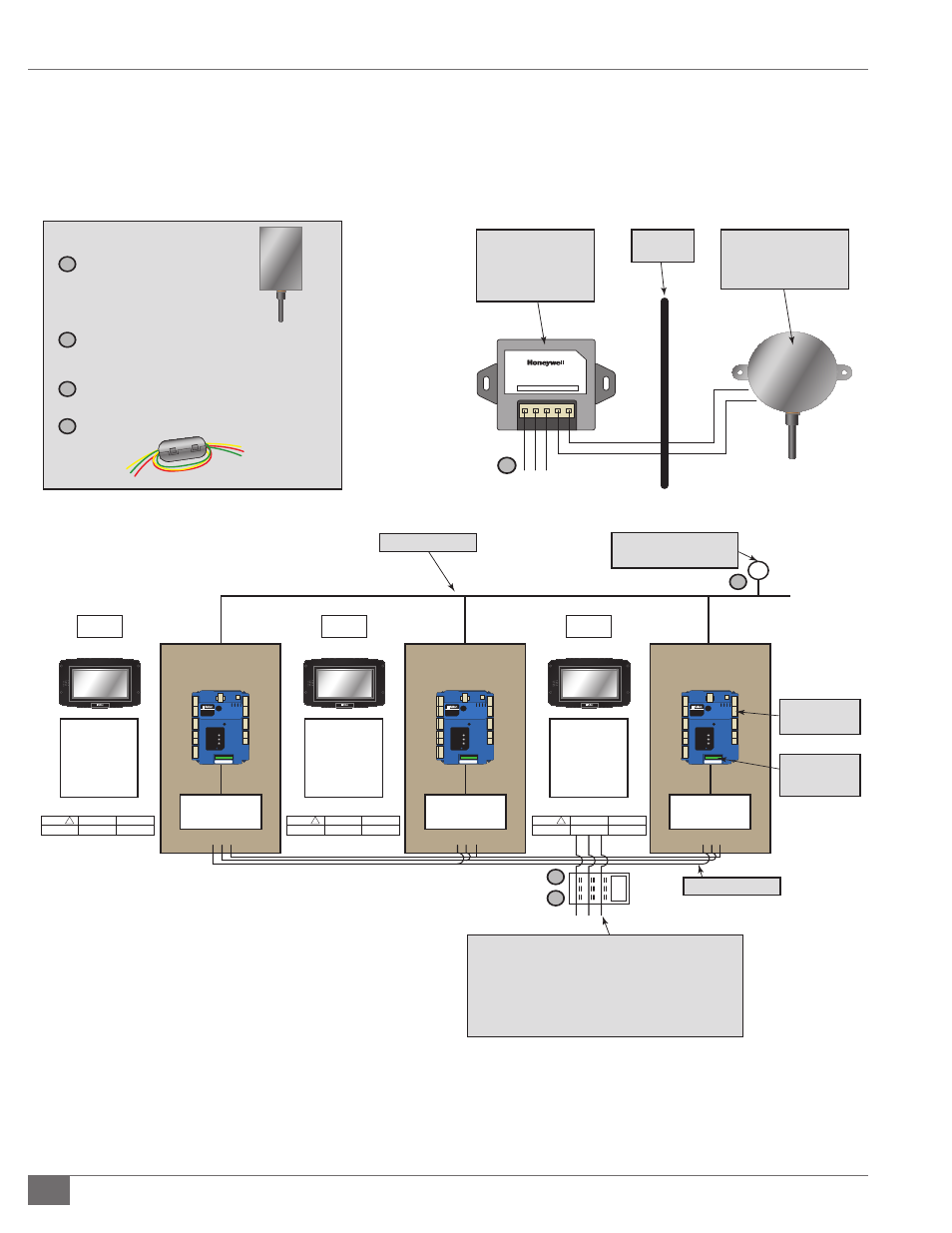

J3 ECOM 1,2,3

For Outdoor

Sensor Interface

Module

J8 (S5) terminals

11 & 12 For

Header Sensor

POWER

FLAME

ALARM

RESET

2-40-000907

BOILER

Master

A B C

J3 (MB1) A,B,C

For daisy chain of

boilers

Com 1 and 24

VAC of the

display will be

pre-wired at the

factory

S7999D

Display

POWER

FLAME

ALARM

RESET

2-40-000907

BOILER

Lag

A B C

J3 (MB1) A,B,C

For daisy chain of

boilers

Com 1 and 24

VAC of the

display will be

pre-wired at the

factory

S7999D

Display

POWER

FLAME

ALARM

RESET

2-40-000907

BOILER

Lag

A B C

J3 (MB1) A,B,C

For daisy chain of

boilers

Com 1 and 24

VAC of the

display will be

pre-wired at the

factory

S7999D

Display

COM 1

1

COM 2

24 VAC

A

B

C

A

B

C

COM POWER

COM 1

1

COM 2

24 VAC

A

B

C

A

B

C

COM POWER

COM 1

1

COM 2

24 VAC

A

B

C

A

B

C

COM POWER

C

la

m

p

Fi

lt

er

TE

Water Header

Honeywell Header

Sensor and Well

Outdoor Sensor Interface Module

1

2

3

OT

OT

Communication wire, Modbus for BMS

RS-485 message format:

1 start bit

8 data bits

No parity bit

1 stop bit

Note: If boilers are daisy chanied together only one BMS

connection is required to the master.

Communication wire

Outside

Wall

Outdoor Sensor

Interface Module,

mounted inside as

close to outdoor

sensor as possible

Honeywell Sensor and Well

Outside Air Sensor

2 wire, landed on

“OT” of interface

Module, Field Wiring

Ou

td

oo

r S

en

so

r

1

3 Wires Connected to Master Boiler

(J3 ECOM terminals 1,2 and 3), Field Wiring

2

Field Wiring

3

Clamp Filter all connections to D display

4

4

3

1

2

He

ad

er

Se

ns

or

FIGURE 51 - LEAD/LAG OF HYDRONIC BOILERS USING THE SOLA CONTROL (MAXIMUM OF 8 BOILERS)