Installation – Fulton Pulse HW (PHW) Fully Condensing Hydronic Boiler User Manual

Page 33

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 2

PHW-IOM-2013-0214

INSTALLATION

2-27

shutoff valve for the pressure reducing (fi ll) valve, and

all manual air vents.

2. Open all other system shutoff valves one of the zone

valves, the vent on the combination shutoff / purge

valve, and the shutoff valve to the pressure reducing

(fi ll) valve.

3. Water will now begin to fi ll the system. Air will escape

through the vent on the combination shutoff / purge

valve. Continue fi lling until a constant stream of water

(no bubbling) is discharged from the vent.

4. Close the zone valve on the purged loop, and open the

zone valve on the next loop to be purged. When all air

has escaped and only water is discharged, close the

zone valve. When all zones have been purged. (one at a

time), close the vent on the combination shutoff / purge

valve.

5. At this point, the system has been initially fi lled.

However, air pockets may still remain at high points

in the system and in heating loops above the level

of the combination shut/off purge valve. It is quite

possible, depending on the particular system that all

RETURN FROM

SPACE HEATING SYSTEM

DRAIN

9

13

10

12

11

10

9

7

14

*

*ALTERNATE LOCATION

COLD

WATER

SUPPLY

BOILER

1

2

3

4

5

7

8

6

HIGH POINT

AIR VENT

VENT

(TYPICAL)

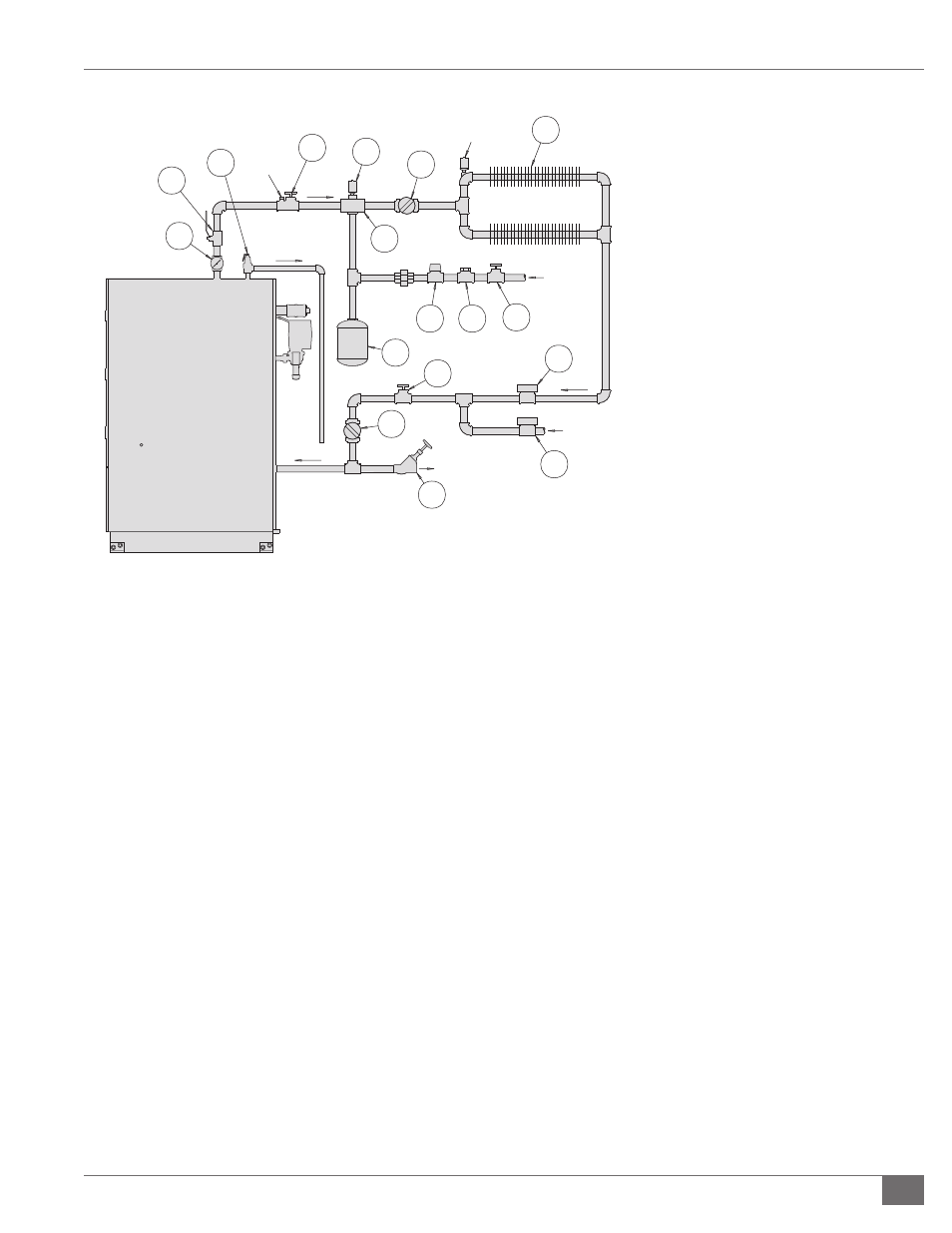

FIGURE 21 - PURGE EXAMPLE

Legend:

1. Temperature/ Pressure

Indicator

2. Hot Water Outlet Stop Valve

3. Safety Valve

4. Combo Shutoff / Purge Valve

5. Auto Air Vent

6. Air Scoop

7. Circulator

8. Heat User

9. Zone Valve

10. Stop Valve

11. Check Valve

12. Pressure Reducing Valve

13. Diaphragm Expansion

Tank

14. Drain Valve

piping above the combination shutoff /purge valve still

contains air. If manual vents are installed on the system

high points, these should be opened to vent these

locations. When only water is discharged from all vents,

the initial purging is complete.

6. Open the combination shutoff / purge valve (keep the

vent closed). With the gas shutoff valve closed, turn on

power to the boiler and operate the circulator. Circulate

the system water for approximately 30 minutes to move

all air to the automatic air separation point.

7. Again, open manual air vents at high points of heating

loop until a constant stream of water is discharged from

the vent. Close the vent and make sure it’s watertight.

Repeat procedure for all high points and for every zone.

8. Check temperature/pressure indicator reading, which

should equal the pressure reducing (fi ll) valve set

pressure. No more water should be entering the system.

Close the shutoff valve on the cold water fi ll line.

9. Visually inspect all pipe joints and equipment

connections for leaks. If necessary, drain system, repair

leaks and refi ll/purge the system. If no pressure drop is

detected for a period of two hours under pressure, the