Installation, The fulton companies 2013 – Fulton Pulse HW (PHW) Fully Condensing Hydronic Boiler User Manual

Page 28

© The Fulton Companies 2013

INSTALLATION

PHW-IOM-2013-0214

SECTION 2

2-22

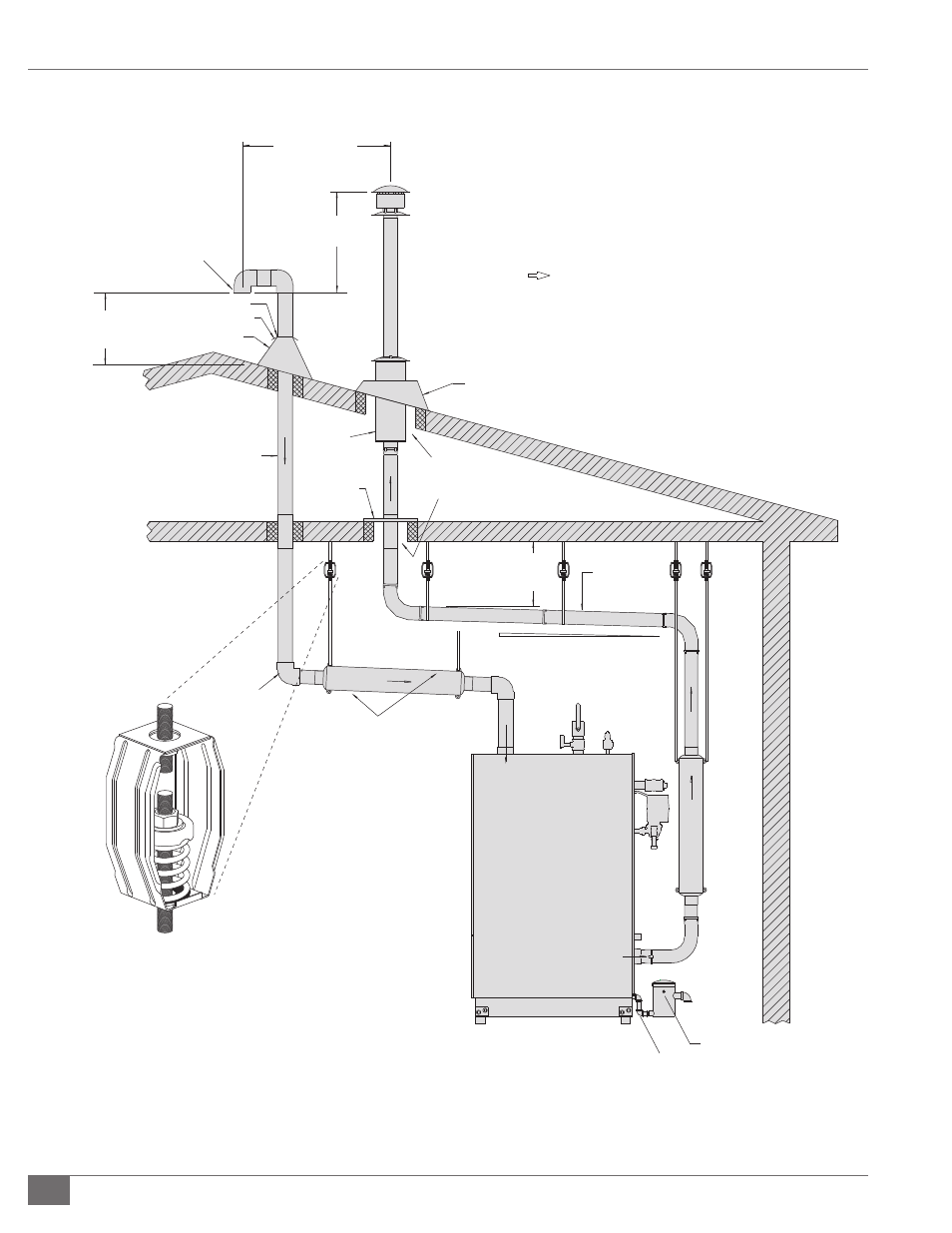

90° ELBOW

WIRES AND INSULATION

TO COMBUSTABLES,

AIR SPACE CLEARANCES

MAINTAIN MIN 9" / 22.86 CM

EXHAUST PIPE

& FITTINGS

AL294C

AIR INLET

RISE TO RUN: 1/4" PER FOOT

Pulse

Boiler

( SIDE VIEW )

1/4" TAPPING FOR WATER\

100 PSI MAXIMUM

INSTALL SUPPORT STRAPS AND SPRING HANGERS

AT 5FT / 152CM HORIZONTAL

INTERVALS AND AT ELBOWS

( SPRING HANGERS ARE REQUIRED )

SUPPORT

ROOF

RECIRCULATION DURING DIFFERENT

POSSIBLE TO PREVENT FLUE GAS

SHOULD BE SEPERATED AS FAR AS

AIR INTAKE AND EXHAUST TERMINATION

NOTE:

( } 3 IN. / 7.62 CM )

4FT / 122 CM

FLASHING

ADJUSTABLE

SPACE CLEARANCE

IN REQUIRED AIR

INSULATION

DO NOT PLACE

PVC PIPE

FIRE STOP

METAL PLATE

PIPING

ABOVE AIR INTAKE

MIN 4FT / 122 CM

ADJUSTABLE

FLASHING

ADHESIVE SEAL

STORM COLLAR

OF AIR INTAKE OPENING

EXHAUST STACK IS DOWNWIND

SCREENED INLET

IF SNOW ACCUMULATION IS

APPLICABLE, OPENING TO BE

1 FT. / 30 CM ( MIN. ) ABOVE THIS

NORMALLY EXPECTED LEVEL.

( SUGGESTED TERMINATION CONFIGURATIONS )

TYPICAL ROOF PENETRATIONS

WIND CONDITIONS.

NOTE: STACK SHOWN IS FOR REFERENCE PURPOSES ONLY. OTHER CONFIGURATIONS MAY BE ACCEPTABLE.

EXHAUST

USE OF ISOLATION CUBES OR SPRINGS IS REQUIRED

EXAMPLE OF SPRING HANGER

PROPER TRAP HEIGHT MUST BE ACHEIVED, AS SHOWN IN FIGURE 7

FIGURE 14 - TYPICAL CEILING AND ROOF PENETRATION DETAIL