Installation, Rating the boiler – Fulton Pulse HW (PHW) Fully Condensing Hydronic Boiler User Manual

Page 35

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 2

PHW-IOM-2013-0214

INSTALLATION

2-29

2. Replace the plug with a 1/4 N.P.T. to 1/4” compression

(or fl are) adaptor and a short piece of tubing. Connect a

piece of rubber hose from the tubing to a manometer.

Open the gas shutoff valve (gas cock) and turn on

boiler.

3. Inlet Pressure for Natural gas fi red units should be a

minimum of 7” WC while running. Inlet pressure for

Propane should be a minimum of 11”WC while running.

See factory test fi re sheet for manifold operating

pressures.

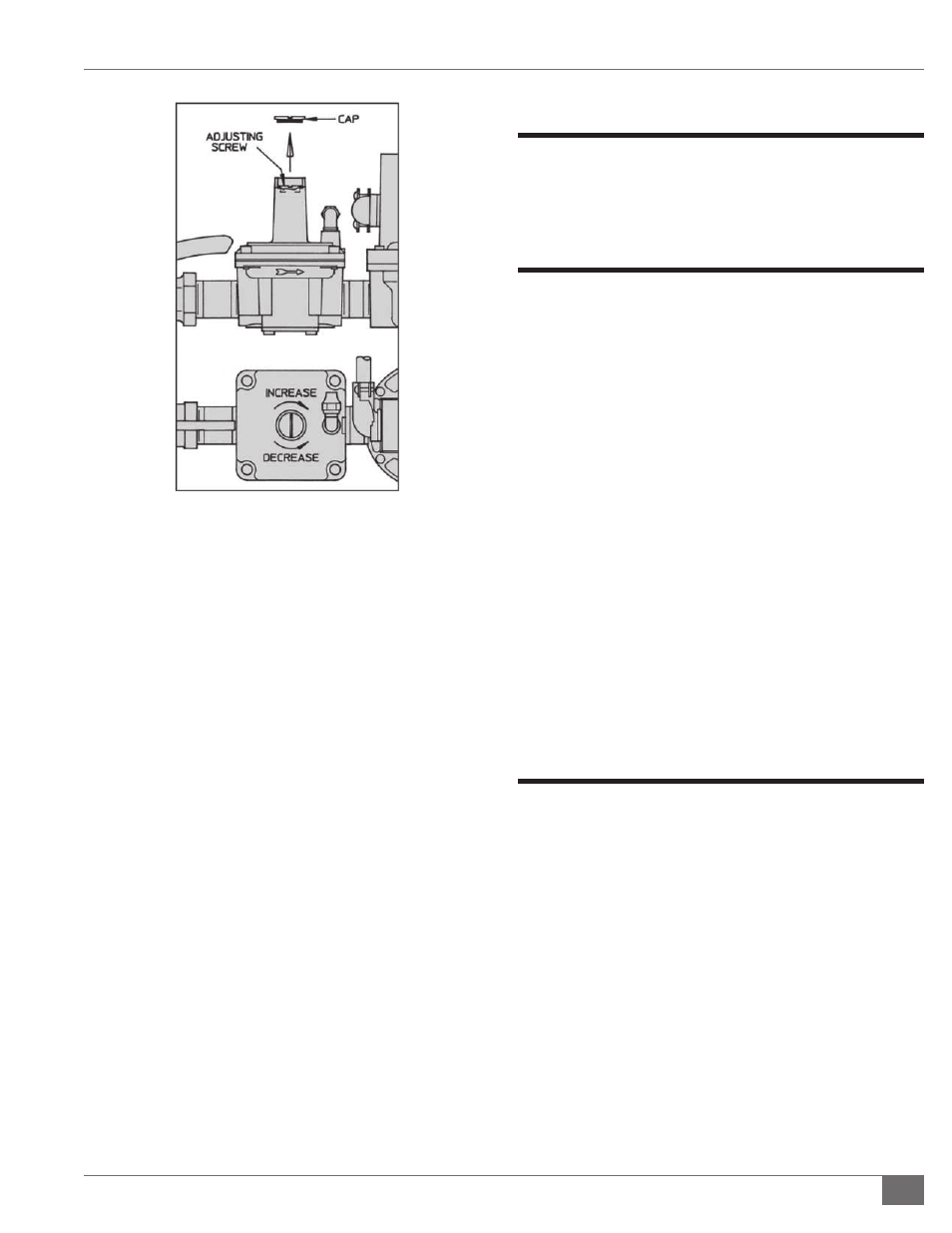

To Correct Input – Adjust Gas Pressure Regulator

Perform the following:

1. Turn boiler off and remove cap from regulator. (Figure

22).

2. Turn adjusting screw clockwise to increase gas fl ow.

Turn adjusting screw counter-clockwise to decrease gas

fl ow.

3. Always replace cap before turning on boiler.

4. Regulator vent must terminate outdoors.

5. A fl ow restricting bleed valve shall not be used on the

regulator vent.

FIGURE 22 - REMOVING CAP FROM REGULATOR

Rating the Boiler

After the boiler has been operating for about 15 minutes,

check gas input rate to be sure boiler is operating at design

capacity.

To Check for High Gas Pressure

Adhere to the following:

1. The boiler and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.5 kPa).

2. Turn off boiler and turn off gas supply to manual

gas shutoff valve. Remove the pressure test plug on

manual shutoff gas valve. Replace with a 1/4” NPT to

1/4” compression (or fl ange) adaptor and a short piece

of tubing. Connect a piece of rubber hose from tubing

to a manometer.

3. Open gas supply to manual gas shutoff valve and turn

on boiler. After combustion starts, manometer should

read 7” WC (178mm) minimum for natural gas and 11”

WC (25mm) minimum for propane.

4. If reading exceeds 14” WC. (178mm) install regulator

upstream of gas valve to reduce pressure.

For High Gas Pressure Installations Using

Fisher Regulators

In high gas pressure areas, it is good practice to step the

pressure down as described below:

1. Locate the stepdown regulator as far away from the

Pulse boiler as possible. At a minimum, it should be 10

feet from boiler.

2. When stepping down from more than 5 psig to 14” WC,

the stepdown should be done in two steps:

Reduce the pressure to 5 psig

Reduce the pressure from 5 psig to 14” WC

3. The preferred stepdown regulator for this application is

manufactured by Fisher. Consult your Authorized Fulton

Representative for selection. This recommendation is

made to avoid regulator chatter. It is also recommended

to avoid high lockup pressures which can cause light off