Installation, Air intake supply and exhaust vent installation – Fulton Pulse HW (PHW) Fully Condensing Hydronic Boiler User Manual

Page 26

© The Fulton Companies 2013

INSTALLATION

PHW-IOM-2013-0214

SECTION 2

2-20

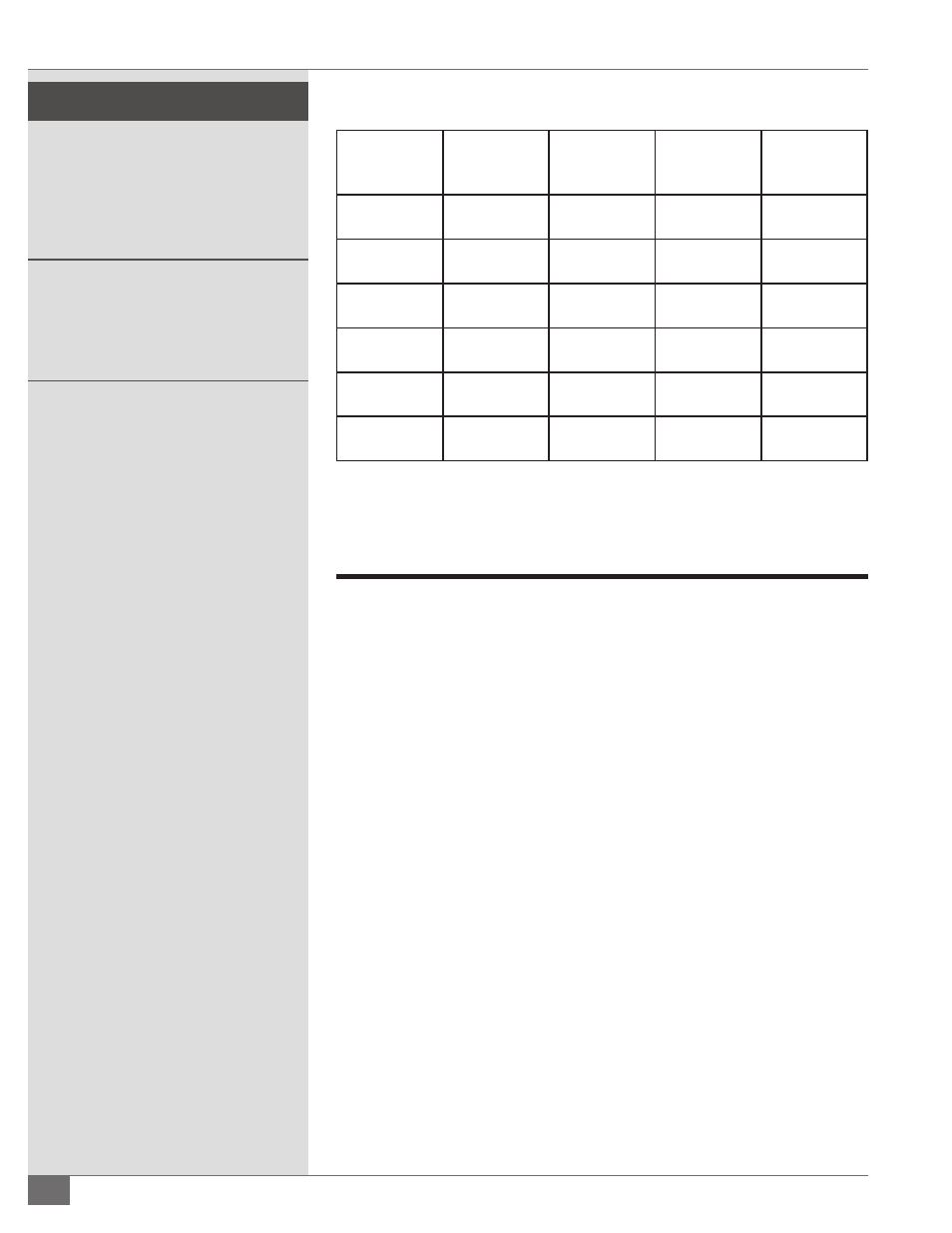

TABLE 3 - EXHAUST VENT PIPING REQUIREMENTS

Model PHW

Type

Base

Diameter

(inches)

Length (feet)

Number of

90-degree

Elbows

300

Stainless Steel

AL294C

4

4

10 minimum

35 maximum

0

4

500

Stainless Steel

AL294C

4

4

10 minimum

35 maximum

0

4

750

Stainless Steel

AL294C

4

4

10 minimum

35 maximum

0

4

1000

Stainless Steel

AL294C

4

4

10 minimum

35 maximum

0

4

1400*

Stainless Steel

AL294C

4

6

10 minimum

35 maximum

0

4

2000

Stainless Steel

AL294C

6

6

10 minimum

35 maximum

0

4

*A minimum 10 feet of 4 inch air intake and exhaust is required for the PHW-1400. Air

intake and exhaust confi gurations over 10 feet in length will require 4 inches for the fi rst

10 feet from the boiler, and then 6 inches up to an additional 40 feet, and four elbows.

Air Intake Supply and Exhaust Vent Installation

Adhere to the following for air intake supply and exhaust vent installation:

1. Air intake supply and exhaust vent pipes and fi ttings are suitable for

vertical, through-the-roof or horizontal through-the-wall installation.

The vent system must be installed in accordance with the manufacturer’s

instructions.

2. All vent pipes and fi ttings must be installed with appropriate air space

clearances to combustibles. These air space clearances apply to indoor or

outdoor vents—whether they are open, enclosed, horizontal or vertical or

pass through fl oors, walls, roofs, or framed spaces. See Figure 14. The air

space clearances should be observed to joists, studs, subfl oors, plywood,

drywall or plaster enclosures, insulating sheathing, rafters, roofi ng, and any

other material classed as combustible.

3. The required minimum air space clearances also apply to electrical wires

and any kind of building insulation away from gas vent and out of the

required air space clearance.

4. Vertical runs or vent pipes and fi ttings passing through fl oors, ceilings, or

in framed walls must be fi re stopped at fl oors and ceilings. The fi re stop

must close in the area between the outside of the vent and the opening in

the structure. (Figure 15). When passing through a fl oor or ceiling frame,

provide an opening 5” to 9” air space clearance to vent pipe as applicable.

The fi re stop fi ts to the bottom of a framed opening 13 1/4” square. Nail

into the inside of the framed opening through the four holes in the ring.

The fi re stop is placed on top of a framed opening 14 1/4” square with the

dished position down. Nail the fl ange to the top of the framing.

!

WARNING

Do not attempt to start boiler before

fi lling and purging boiler heating system.

A dry fi re will seriously damage the boiler

and may result in property damage or

personnel injury and is not covered by

warranty.

Operating the boiler beyond its design

limits is dangerous and may also cause

boiler damage. Do not attempt to upgrade

boiler performance with unapproved

modifi cations.