Maintenance – Fulton Vantage (VTG) Fully Condensing Hydronic Boiler User Manual

Page 63

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 4

VTG-IOM-2013-0815

MAINTENANCE

4-11

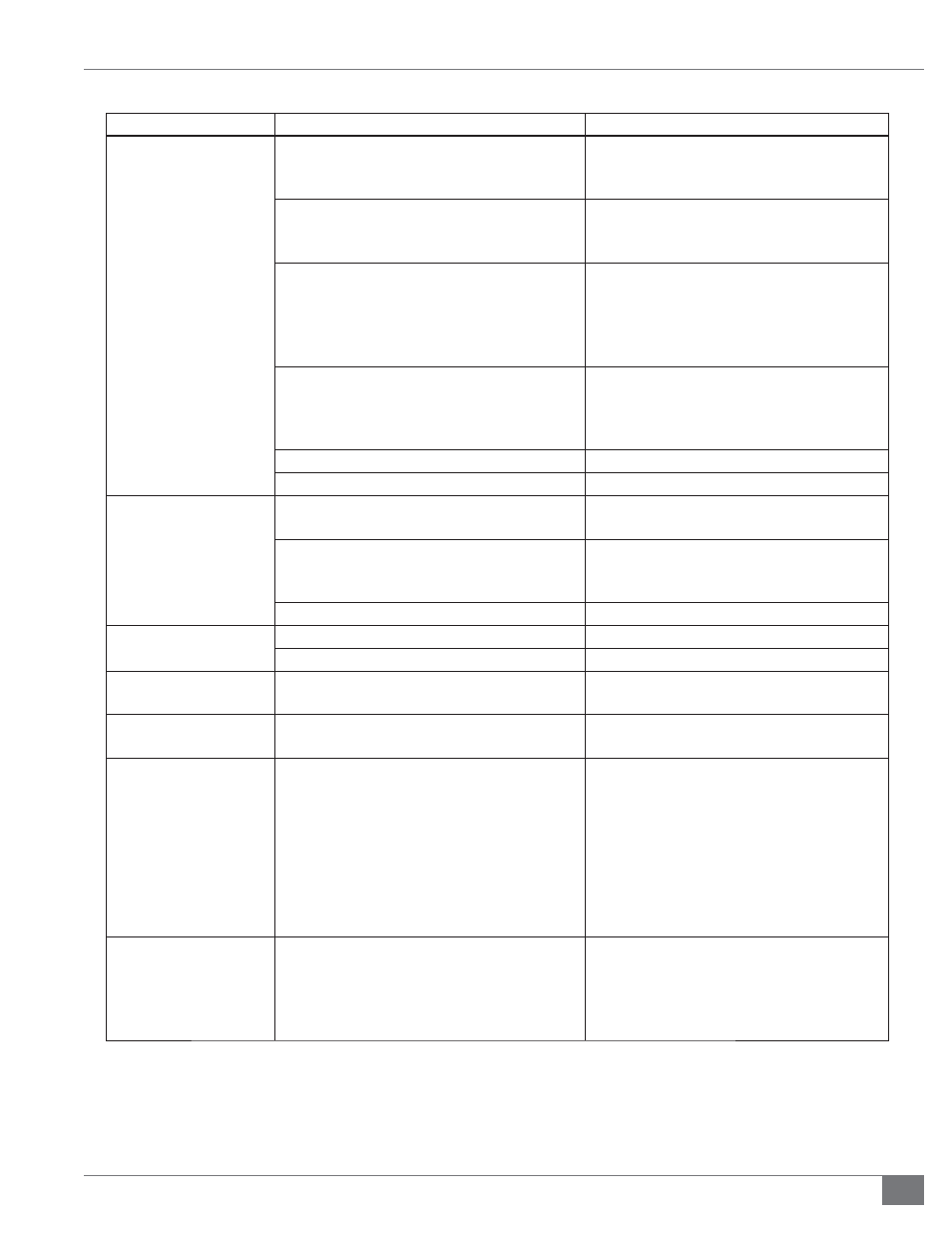

PROBLEM

CAUSE

CHECK

Main fl ame fails

Gas actuator not set properly

1. Verify the last elbow gas pressure matches the

start up report.

2. Adjust actuator setting.

Air actuator not set properly

1. Verify the over burner pressure matches the start

up report.

2. Adjust actuator motor.

Flame detector failure

1. Visually verify the fl ame through the sight glass.

2. Remove fl ame detector and visually verify the

fl ame through the scanner tube.

3. Verify the fl ame detector eye is not dirty.

4. Replace scanner.

Insuffi

cient Gas Supply

1. Verify the manual shut down valves are open,

allowing gas fl ow through the gas train.

2. Adjust incoming gas pressure to match the start

up report.

Gas Filter Blocked

Replace gas fi lter.

Air supply blocked (direct vent only)

Verify venting is not obstructed.

Boiler fails while

modulating

Gas actuator not set properly

1. Verify the last elbow matches the start up report.

2. Adjust actuator setting.

Air actuator not set properly

1. Verify the over burner pressure matches the start

up report.

2. Adjust actuator setting.

Air supply blocked (direct vent only)

Verify venting is not obstructed.

Poor combustion

Gas actuator not set properly

Adjust actuator setting.

Air actuator not set properly

Adjust actuator setting.

Manual Reset limit device

trips

Manual Reset Limits include: Flame safeguard, high

or low gas pressure, high temperature limit

DO NOT reset without determining and correcting

the cause.

Power outage to the boiler

room

Entire boiler system is disabled and de-energized.

When power has returned, the boiler will have to be

manually reset, as it will be in the lockout position

Gas Pressure alarm is

annunciated

Either insuffi

cient gas pressure or the gas pressure

to the manifold is too high for safe and proper

operation of the boiler. This shuts down the burner.

When gas pressure is restored, the annunciated

alarm will remain on and the boiler will remain

locked out until the gas pressure switch is manually

reset.

Locate cause and correct.

In the event of a high

gas manifold pressure condiƟ on, qualifi ed service

personnel must correct the problem before

restarƟ ng the boiler.

High water temp alarm is

annunciated

Boiler water has exceeded both the operating and

high-limit temperature. When the water temperature

falls below the high-limit temperature, the boiler will

remain locked out until the controller is manually

reset.

Locate cause and correct. Once the control is reset,

the sequence returns to normal operation provided

that the other limits are satisfi ed.