Installation – Fulton Vantage (VTG) Fully Condensing Hydronic Boiler User Manual

Page 26

© The Fulton Companies 2013

2-20

INSTALLATION

VTG-IOM-2013-0815

SECTION 2

7. Make-up air ventilation openings are recommended for each installation

size in Table 5:

TABLE 5 - MAKE-UP AIR VENTILATION OPENINGS

Total Input of boiler

1000 BTU/HR

(kW/HR)

Free Area

square feet

(meters)

2000 (.58)

6 (.55)

2500 (.73)

9 (.83)

3000 (.87)

11 (1.02)

3500 (1.02)

13 (1.20)

4000 (1.17)

14 (1.30)

5000 (1.46)

18 (1.67)

6000 (1.75)

21 (1.95)

8. For multiple boiler installations, multiply the number of boilers by required

free area per boiler.

9. The installation of exhaust fans in a boiler room is not recommended.

10. An exhaust fan or similar equipment can create down draft in the stack or

restrict the burner’s air supply which will result in poor combustion. It is

essential that only fresh air is allowed to enter the combustion air system.

Foreign substances, such as combustible volatiles in the combustion

system can create hazardous conditions. If foreign substances can enter

the air stream, the boiler combustion air inlet must be piped to an outside

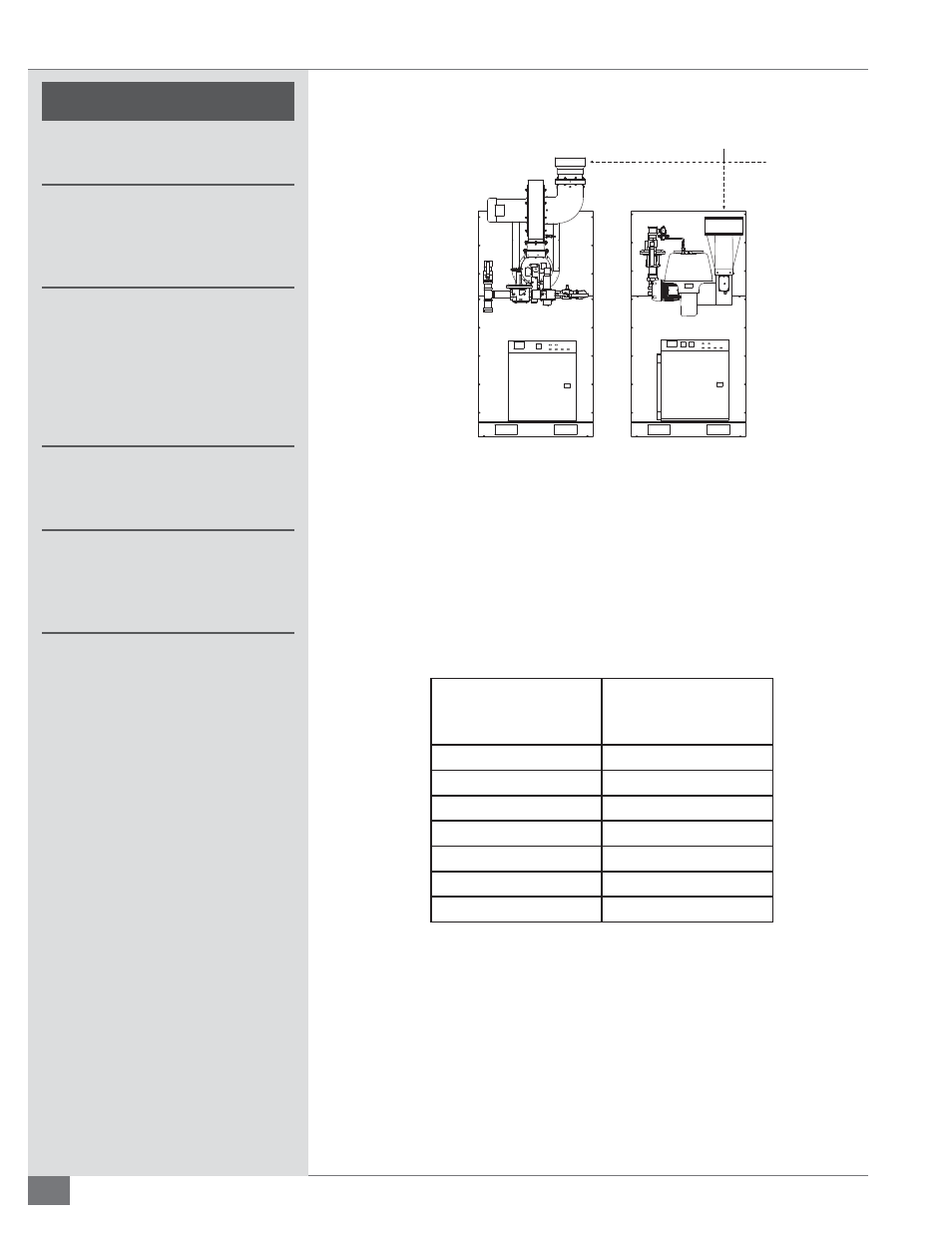

AIR INLETS

Standard Configuration

Riello Burner

FIGURE 11 - AIR INLET LOCATIONS

ã

WARNING

Do not terminate venting into an

enclosed area.

Never use open fl ame or smoke from

a cigarette, cigar, or pipe as a testing

method during boiler installation,

operation, or maintenance.

Foreign substances, such as

combustible volatiles in the

combustion system can create

hazardous conditions. If foreign

substances can enter the air stream,

the boiler combustion air inlet must

be piped to an outside location.

Ensure tank return line is not clogged.

Obstructions in the line could cause

damage to the pump seal.

Regular maintenance of the

fi lter is required (as per the fi lter

manufacturer’s recommendations) to

maintain the Vantage warranty.