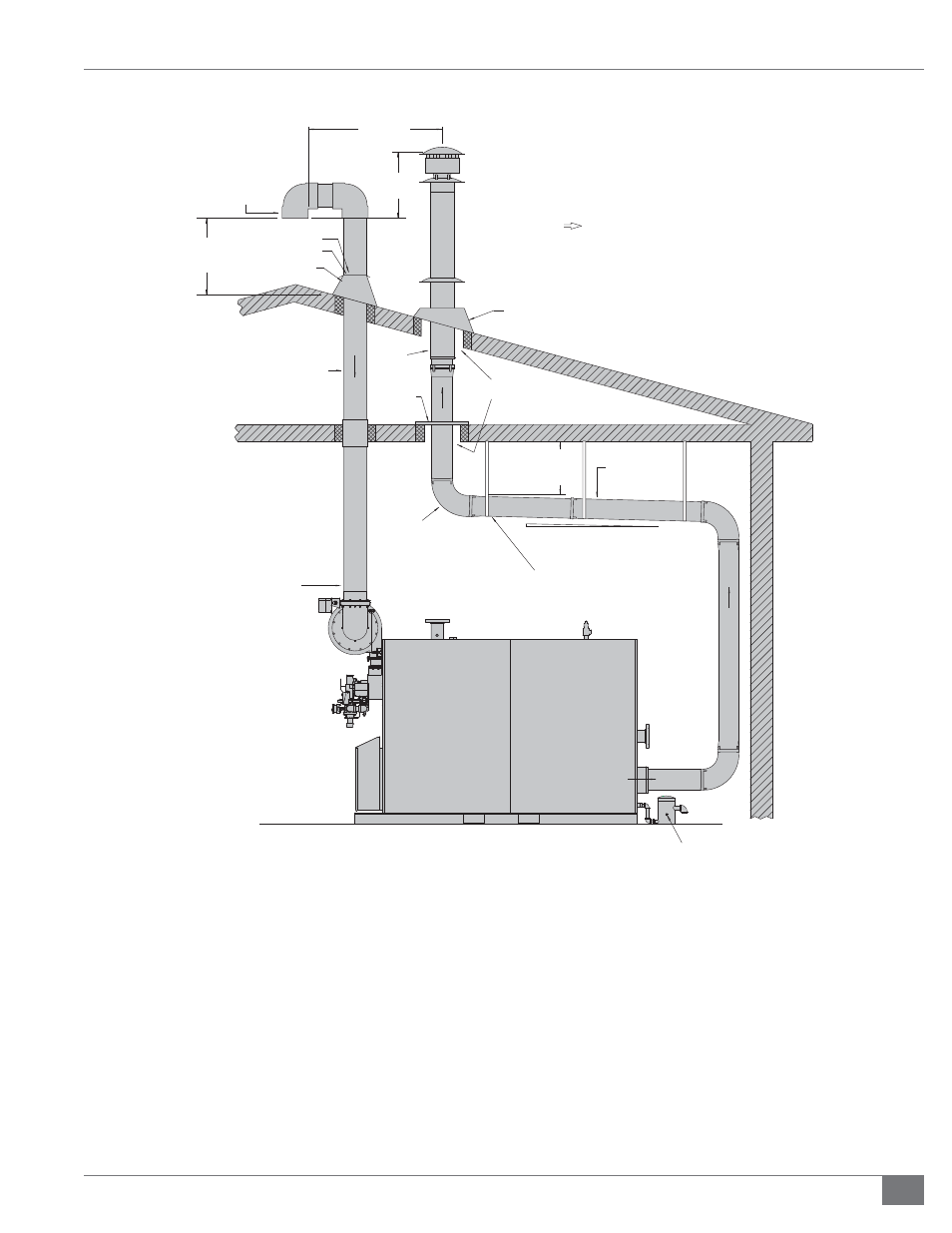

Installation, Typical roof penetrations, Figure 12 - roof penetration details – Fulton Vantage (VTG) Fully Condensing Hydronic Boiler User Manual

Page 29

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 2

VTG-IOM-2013-0815

INSTALLATION

2-23

the following items must be considered and addressed by the

parties responsible for designing and providing that system:

MULTIPLE BOILERS SHARING AN EXHAUST STACK, NEGATIVE

PRESSURE IN THE COMMON HEADER:

1. Precautions must be taken to ensure that the negative

pressure in the common header stays within the stated

ranges (refer to table 4) at all possible conditions. This

includes considering all possible operating conditions

of the stack, including:

All boilers on at their maximum input rating capacity

One boiler in the system on at a low fi re position

No boilers on, light off condition

2. Draft accessories, such as stainless steel dampers, may

be required depending on the variety of conditions

experienced in the draft system.

1/4" TAPPING FOR WATER

100 PSI MAXIMUM (U.S. ONLY)

ROOF

SUPPORT

4FT 3 IN

( 130 CM )

ADJUSTABLE

FLASHING

PVC PIPE

RISE TO RUN: 1/4" PER FOOT (2.12 CM/M)

METAL PLATE

FIRE STOP

MIN 4FT / 122 CM

ABOVE AIR

INTAKE PIPING

ADJUSTABLE

FLASHING

ADHESIVE SEAL

STORM COLLAR

SCREENED INLET

IF SNOW ACCUMULATION

IS APPLICABLE, OPENING TO BE

1 FT. / 30 CM ( MIN. ) ABOVE

THIS NORMALLY EXPECTED LEVEL.

TYPICAL ROOF PENETRATIONS

( SUGGESTED TERMINATION CONFIGURATIONS )

INSTALL SUPPORT STRAPS AT

5FT / 152CM HORIZONTAL

INTERVALS AND AT ELBOWS

EXHAUST

EXHAUST STACK IS DOWNWIND

OF AIR INTAKE OPENING

DO NOT PLACE INSULATION IN

REQUIRED AIR SPACE CLEARANCE

STAINLESS STEEL

HIGH TEMPERATURE

EXHAUST PIPE & FITTINGS

VANTAGE

HYDRONIC

BOILER

( SIDE VIEW )

NOTE:

AIR INTAKE AND EXHAUST TERMINATION SHOULD BE

SEPARATED AS FAR AS POSSIBLE TO PREVENT FLUE GAS

RECIRCULATION DURING DIFFERENT WIND CONDITIONS.

AIR INLET

MAINTAIN MIN 9" / 22.86 CM

AIR SPACE CLEARANCES

TO COMBUSTABLES,

WIRES AND INSULATION

PVC

90° ELBOW

FIGURE 12 - ROOF PENETRATION DETAILS