Installation, Clearances and serviceability – Fulton Vantage (VTG) Fully Condensing Hydronic Boiler User Manual

Page 10

© The Fulton Companies 2013

INSTALLATION

VTG-IOM-2013-0815

SECTION 2

2-4

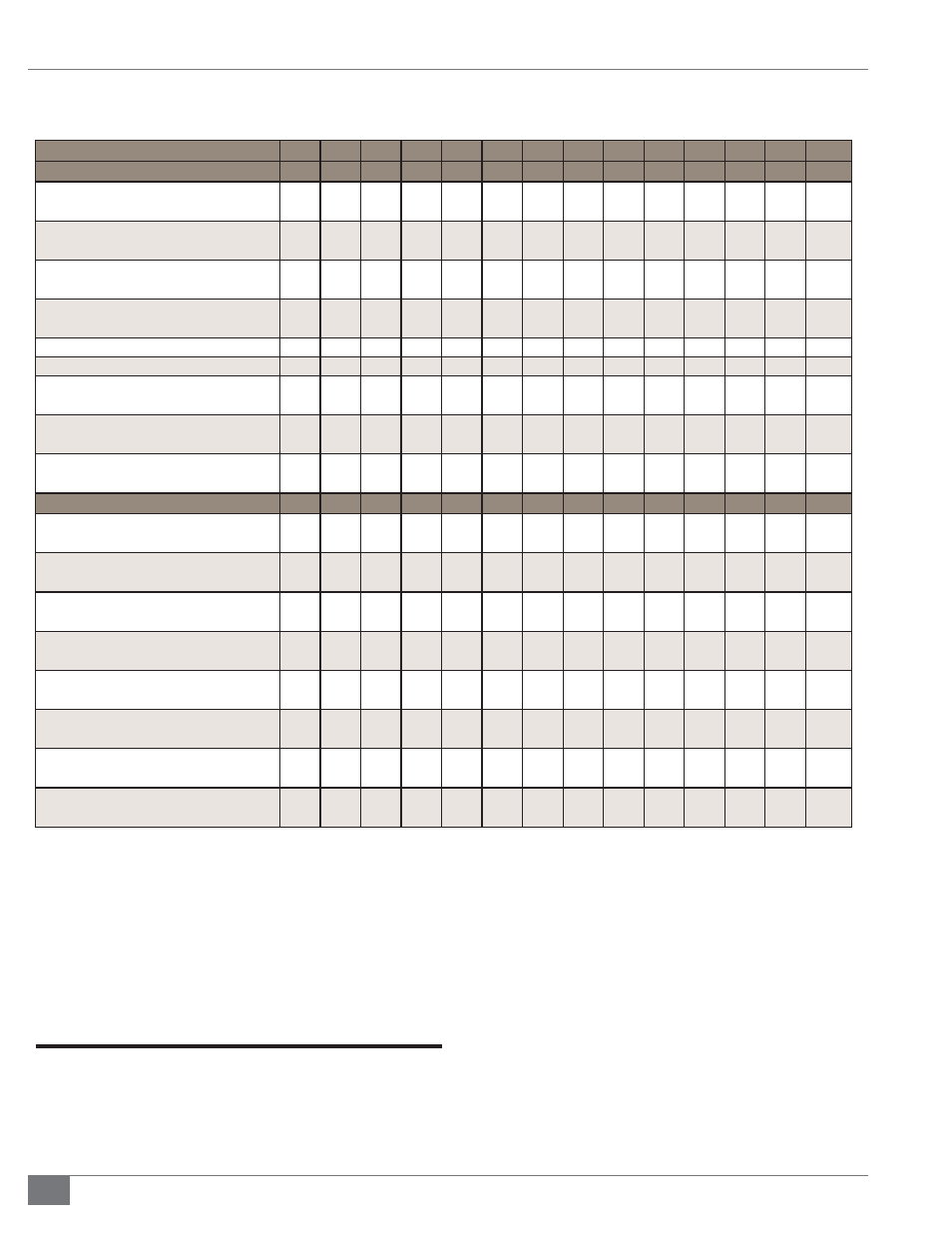

TABLE 1 - BOILER DIMENSIONS AND OPERATING REQUIREMENTS

MODEL VTG

2000

2000DF

2500

2500DF

3000

3000DF

3500

3500DF

4000

4000DF

5000

5000DF

6000

6000DF

Specifi cations

2000LE

3000LE

4000LE

Input Million BTU/Hr.

kW

2

586

2

586

2.5

733

2.5

733

3

879

3

879

3.5

1026

3.5

1026

4

1172

4

1172

5

1465

5

1465

6

1758

6

1758

Fuel Cons. @ rated cap: (Nat. Gas) FT

3

/Hr.

M

3

/Hr

2,000

56.6

2,000

56.6

2,500

70.8

2,500

70.8

3,000

84.9

3,000

84.9

3,500

99.1

3,500

99.1

4,000

113.2

4,000

113.2

5,000

141.5

4750

134.5

6,000

169.9

6,000

169.9

Fuel Cons. @ rated cap.: (#2 Oil) GPH

LPH

NA

NA

14.3

54.1

NA

NA

14.3

54.1

NA

NA

21.4

81.0

NA

NA

21.4

81.0

NA

NA

28.6

108.2

NA

NA

27.17

102.8

NA

NA

42.8

162.0

Output at AHRI Test Condition BHP

KCal/h

57

4.8

57

4.8

69

5.8

69

5.8

86

7.25

86

7.25

96

8.0

96

8.0

116

9.7

116

9.7

138

11.6

138

11.6

168

14.1

168

14.1

Electrical Req. (Amps) 230V, 60Hz, 3 Phase

6.8

13.4

12.9

16.1

12.9

16.1

18.5

16.1

18.5

16.1

23

29.2

23

29.2

460V, 60Hz, 3 Phase

3.4

6.7

6.5

8.1

6.5

8.1

9.3

8.1

9.3

8.1

11

16.6

11

16.6

Water Content Gal

Liters

147

556.4

147

556.4

147

556.4

147

556.4

215

813.8

215

813.8

215

813.8

215

813.8

275

1041

275

1041

275

1041

275

1041

480

1817

480

1817

Dry Weight LB

KG

3,800

1724

3,800

1724

3,800

1724

3,800

1724

5,200

2359

5,200

2359

5,200

2359

5,200

2359

5,800

2631

5,800

2631

5,800

2631

5,800

2631

9,950

4513

10,800

4899

Operating Weight LB

KG

5,100

2314

5,100

2314

5,100

2314

5,100

2314

7,000

3175

7,000

3175

7,000

3175

7,000

3175

8,100

3674

8,100

3674

8,100

3674

8,100

3674

13,950

6327

14,800

6713

Dimensions

A. Boiler Width IN

CM

30.5

77.5

30.5

77.5

30.5

77.5

33.6

85.3

34.65

88.0

34.5

87.6

34.6

87.8

34.5

87.6

40.5

102.8

40.5

102.8

40.5

102.8

40.5

102.8

50.5

128.2

50.5

128.2

B. Overall Boiler Height IN

CM

64

162.5

64

162.5

76

193

72.8

184.9

87

220.9

70.5

179.0

83.9

213.1

76.1

193.2

87.6

222.5

78

198.1

87.6

222.5

79.5

201.9

90

228.6

90

228.6

C. Overall Boiler Depth IN

CM

108

274.3

122

309.8

108

274.3

120

304.8

120

304.8

132

335.2

120

304.8

132

335.2

124

314.9

136

345.4

136

345.4

136

345.4

155

393.7

155

393.7

D. Flue Outlet Diameter IN

CM

10

25.4

10

25.4

10

25.4

10

25.4

12

30.4

12

30.4

12

30.4

12

30.4

14

35.5

14

35.5

14

35.5

14

35.5

14

35.5

14

35.5

E. Air Inlet Diameter IN

CM

8

20.3

10

25.4

10

25.4

10

25.4

10

25.4

10

25.4

10

25.4

10

25.4

12

30.4

12

30.4

12

30.4

12

30.4

12

30.4

12

30.4

F. Water Inlet/Outlet Diameter IN

CM

4

10.1

4

10.1

4

10.1

4

10.1

4

10.1

4

10.1

4

10.1

4

10.1

6

15.2

6

15.2

6

15.2

6

15.2

6

15.2

6

15.2

G. Min. Clearance to Ceiling IN

CM

24

60.9

24

60.9

24

60.9

24

60.9

24

60.9

24

60.9

24

60.9

24

60.9

24

60.9

24

60.9

24

60.9

24

60.9

24

60.9

24

60.9

H. Overall Height (w/o blower) IN

CM

68.1

172.9

64

162.5

64

162.5

68.1

172.9

76.2

193.5

70.5

179.0

76.2

193.5

76.2

193.5

78.5

199.3

78.0

198.1

79.5

201.9

79.5

201.9

90

228.6

90

228.6

Clearances and Serviceability

Adhere to the following for clearances and serviceability:

1. All local and national codes (NFPA, ANSI, UL, CSA,

ASME) must be followed for proper clearances and

serviceability for your boiler or heater. Authorities

having jurisdiction should be consulted before

installations are made.

2. Appropriate front, back, side and top clearances must

be maintained (Figure 1). This will allow access around

the equipment to facilitate maintenance and a safe

* Alternate gas pressure arrangements may apply. Please verify gas pressure ratings for your boiler by viewing the boiler name plate.

** Typical 120 VAC controls allow for a +10% and a -15% voltage fl uctuation.

***Standard confi gurations. Alternate voltages available as an option; please consult factory.

Note: All dimensions are approximate and are subject to change without notice.

The use of propane may be allowable with concentrations up to 5% propylene, also referred to as HD5. Off -standard grades of propane are not permitted. Contact

factory for more information.