Maintenance – Fulton Vantage (VTG) Fully Condensing Hydronic Boiler User Manual

Page 62

© The Fulton Companies 2013

MAINTENANCE

VTG-IOM-2013-0815

SECTION 4

4-10

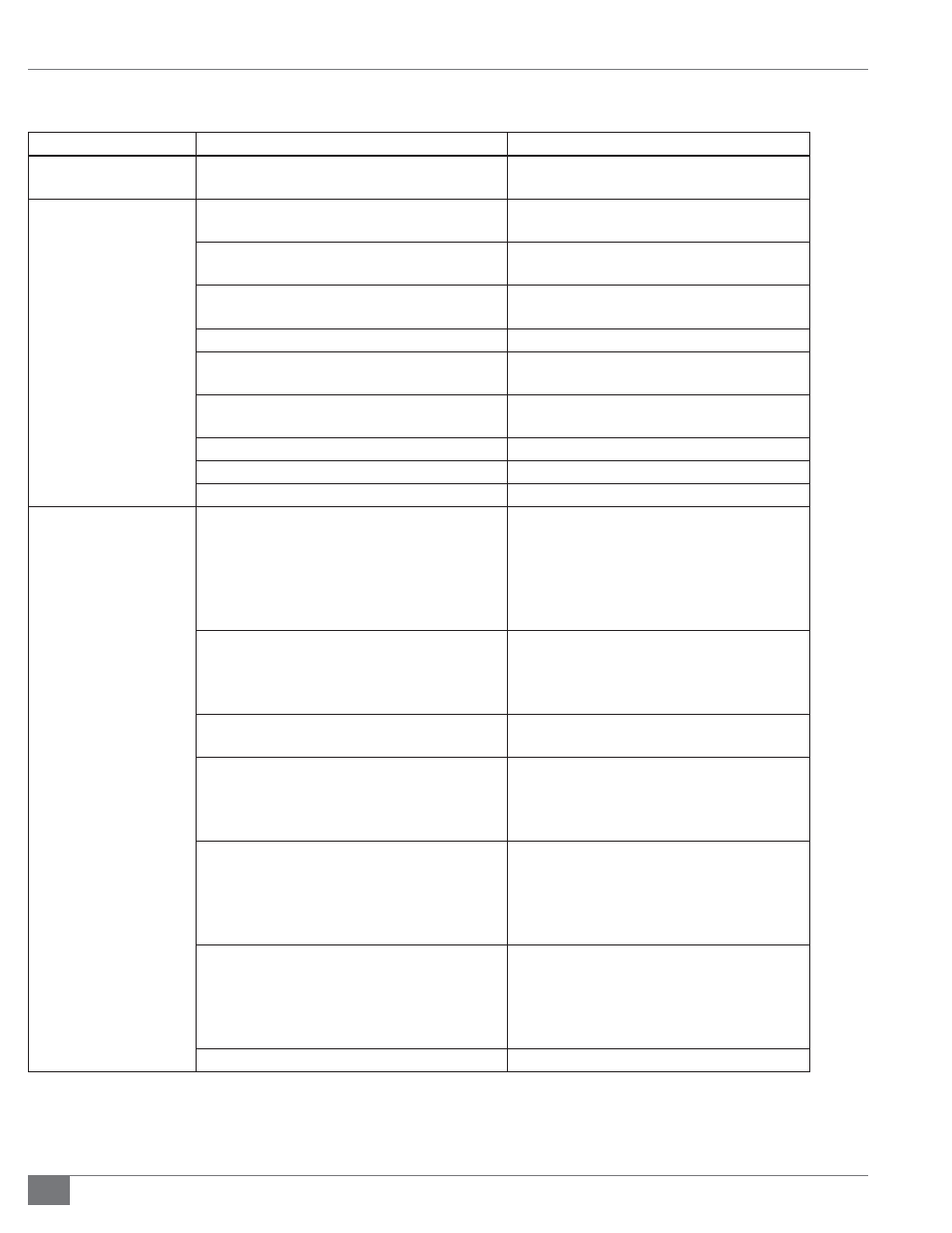

TROUBLESHOOTING

PROBLEM

CAUSE

CHECK

Control does not illuminate

Power supply

Check fuse or circuit breaker. Reset or replace as

necessary.

Fan will not start

High temperature is tripped

1. Reset switch

2. Replace switch

Low gas is tripped

1. Reset switch

2. Replace switch

High gas is tripped

1. Reset switch

2. Replace switch

UT32A incorrectly set/no heat

Adjust UT32A

Flame detector has detected light/scanner

1. Identify light source, remove

2. Replace fl ame detector

Air switch is made when fan is not on

1. Reset switch

2. Replace switch

Blower contactor made when fan not on

Replace motor contactor

Gas valve proof of closure defective

Replace valve

Loose wire connection

Check wiring

Pilot Fails

Insuffi

cient gas supply

1. Verify the manuals shut off valves are open

allowing gas fl ow to the pilot tube.

2. Adjust incoming gas pressure to match the start

up report.

3. Adjust pilot gas pressure regulator to match the

start up report.

Pilot valve fails to open

1. Check pilot gas pressure at the burner.

2. Verify operation of the valve. If pressure does

not increase when the valve is supposed to open,

replace valve.

Air in pilot gas line

Have the boiler attempt to light up to three times. If

the boiler fails to light, call Fulton.

Ignitor failure

1. Check the gap between the top of the electrode

and the pilot tube wall. The gap should be 1/16”

(1.59 mm). Adjust the gap.

1. Check for cracked porcelain. Replace electrode.

Combustion air not suffi

cient

1. Verify the over burner pressure matches the start

up report. Adjust the servo setting.

2. Verify there is enough make up air in the room.

3. (For direct vent only) Verify venting is not

obstructed.

Flame Detector Defective

1. Visually verify the fl ame through the site glass.

2. Remove fl ame detector and visually verify fl ame

through the scanner tube.

3. Verify the fl ame detector eye is not dirty.

4. Replace fl ame detector.

Gas fi lter blocked

Replace gas fi lter.