PASCO ME-9833 Physical Pendulum Set User Manual

Page 9

Physical Pendulum Set

Model No. ME-9833

9

®

2. Use calipers to carefully measure the

distance, L

cg

, from the center of gravity to

one of the other pivot points on the irregular

shape. Record the measurement as L

cg

, the

distance from the center of gravity to the

pivot point.

3. Replace the irregular shape on the Rotary

Motion Sensor by attaching it with one of the

mounting screws through the pivot point that

you used for the measurement.

Data Recording: Parallel Axis

1. Wind the string about the step pulley so that the

mass hanger is just below the Super Pulley. Hold

the irregular shape in place.

2. Start recording data and then release the irregular shape so that it rotates freely.

3. Stop recording data when the mass hanger reaches its lowest point.

4. Repeat the process a total of three times.

Analysis: Parallel Axis

Find the moment of inertia about the parallel axis.

1. Use the same setup in the software to find the average angular acceleration.

2. Calculate the net torque (

τ = rm(g - rα)). Calculate the moment of inertia about the

parallel axis by dividing the net torque by the average angular acceleration

pivot

. Record

the results as the moment of inertia about the parallel axis, I

pivot

.

3. Calculate ML

2

cg

, the moment of inertia about the parallel axis of the irregular shape as if

all its mass is concentrated at its center of gravity. Use the distance from the pivot point to

the center of gravity as L

cg

.

4. Calculate the sum of I

cg

and ML

2

cg

. Compare the sum to the moment of inertia about the

parallel axis, I

pivot

.

5. Find the percent difference between I

pivot

and the sum of I

cg

and ML

2

cg

and record the

percent difference. Set up a graph display in the software of angular velocity versus time.

Extensions

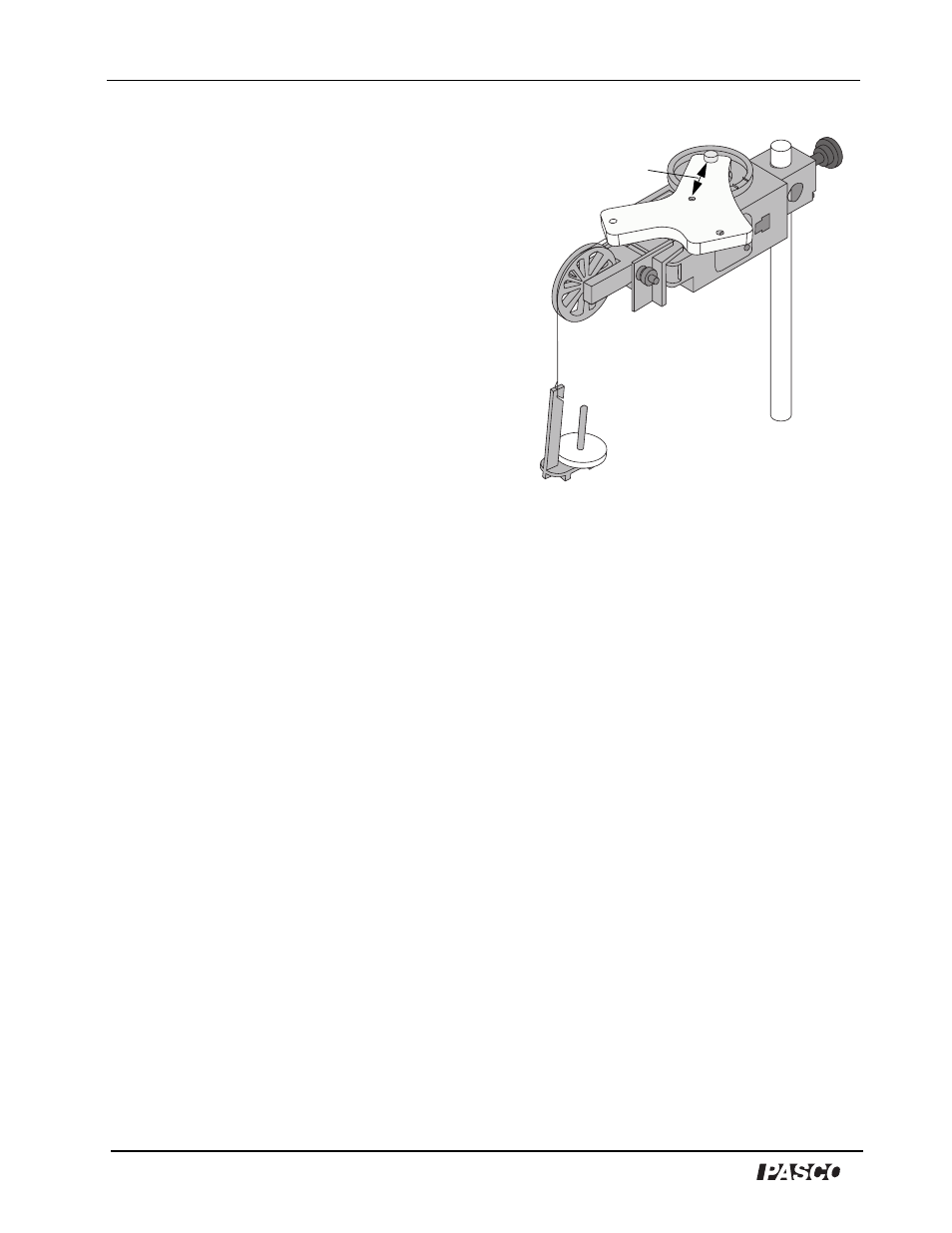

Figure 1-2: Irregular

shape mounted

through a parallel axis

Measure L

cg