Diamond Products CG-2 Mini Groover User Manual

Page 22

Hydraulic Pump Breather Cap

Transmission

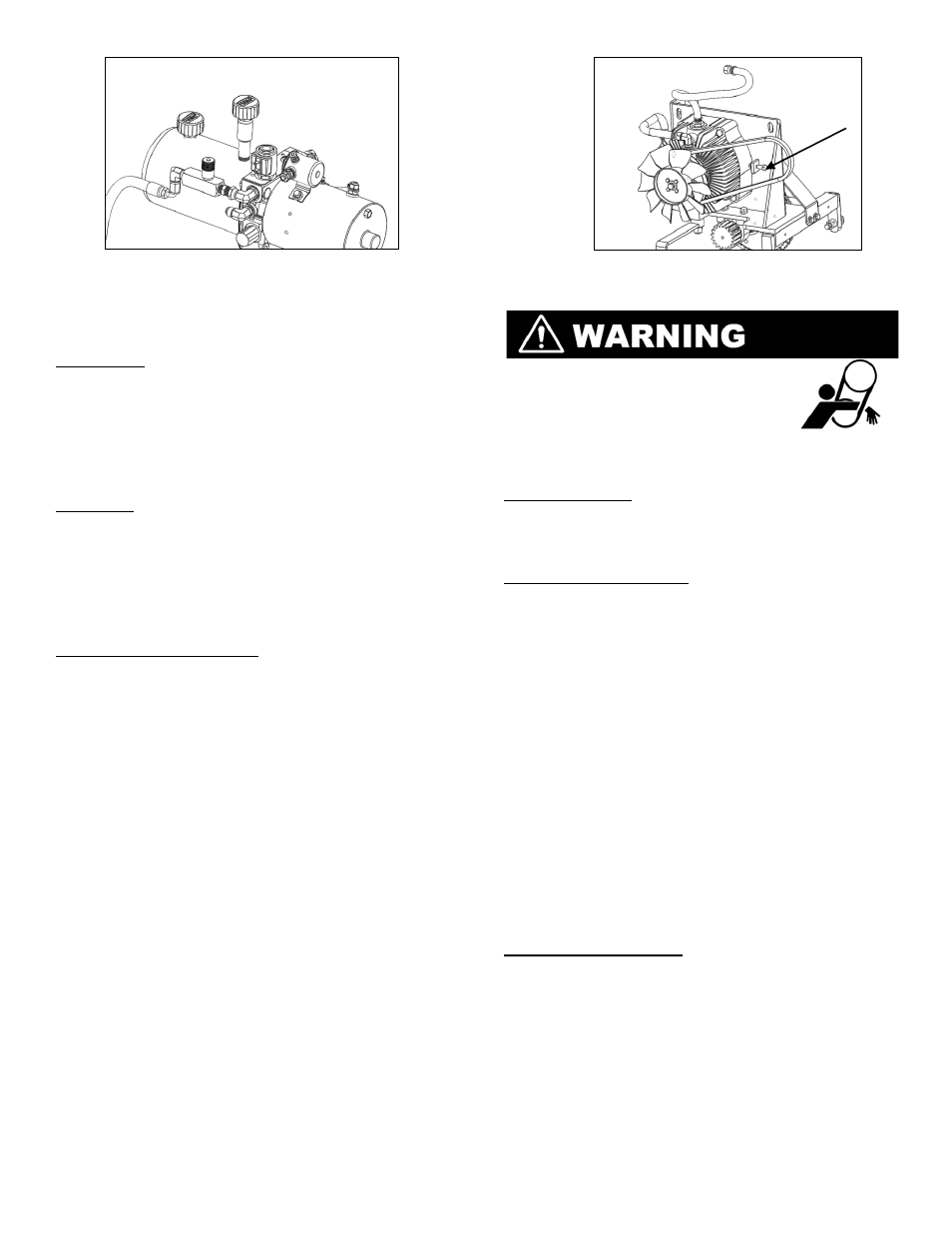

Cooling Fan

• Remove the fan guard and wipe down or

use compressed air to remove debris and

slurry form the transmission cooling fan.

The transmission will not properly cool if the

fan is clogged up with debris.

Adding Oil

• The hydraulic pump supplies oil to the

transmission. Check the oil level daily in the

pump and add DEXTRON II automatic

transmission fluid if necessary. Refer to the

previous section for information on adding

fluid.

Adjusting Rear Drive Chain

• Regularly inspect the rear drive chain and

tighten when necessary. Regularly lubricate

the rear drive chain with oil to increase the

chains life.

1. Remove the rear access panel from

machine.

2. Remover the chain guard.

3. Loosen the four 3/8” hex bolts and nuts

attaching the transmission to transmission

platform, but do not remove.

4. Adjust the set screw (3/8” bolt) that is

located on the front side of the transmission

platform.

5. Turn the set screw clockwise to push

transmission backward in order to tighten

up chain slack. Leave a little slack in the

chain and DO NOT over tighten the chain.

6. Retighten the 4 transmission bolts and hex

nuts.

7. Replace chain guard and rear body access

panel.

Transmission Adjustment Screw

Belt System

• Turn the engine off prior to

performing any belt

maintenance.

• Always let belts cool prior to

performing any belt maintenance.

Blade Drive Belts

There are two five-strand V belts that rotate the

blades shaft via the PTO.

Blade Drive Belt Tension

The manufacturer’s belt tension is set between 68-

70 hertz (Hz). DO NOT exceed the manufactures

tension settings. NOTE: Over-tensioning the belts

may damage the power-take-off (PTO) unit. Under-

tensioning the belts may cause premature wear

and/or poor saw performance. Squealing belts are

an indication that the belts are loose.

Test the belt tension on a daily basis to ensure best

performance and longest life of belts.

• Touch the end of the sonic tension meter

sensor (Available through Diamond

Products) at the midpoint of the longest

section and strum the belt. Adjust the belts

tension if it is lower than the manufacturers

setting.

Adjusting the Belt Drive

1. Remove the belt guard.

2. Inspect belts for and fraying, stress cracks,

and/or breakage and replace immediately if

any damage is found.

3. Test the belt tension, Continue to step 4 if

the belt needs tensioning. Replace belt

guard if no tensioning or replacement is

required.

4. There are two ½-13 retaining bolts on the

front sides of the engine plate. Loosen

20