Diamond Products CG-2 Mini Groover User Manual

Page 12

Inspecting the Blade

Always inspect each blade prior to blade

installation. DO NOT use damaged blades for

cutting in order to avoid injuring yourself, others,

or the machine. Discard all damaged blades and

inspect each replacement blade for deficiencies.

Inspect blades prior to installation for:

• Cracks, Nicks, Or Dents

• A damaged and/or deformed arbor.

• Darkness or discoloration near edges of the

blade.

• A deformed blade circumference.

• Segments missing or cracked.

• Core wear.

• Bending or warpage.

• Uneven side widths.

Blade Speed

Refer to the Diamond Products blade specification

for information on the recommended blade RPM

when cutting. DO NOT use a blade with a lower

maximum operating speed than the blade shafts

speed when cutting.

Blade Shaft Removal

• DO NOT remover or install a

blade shaft with the engine

running.

• Failure to properly secure the

loose flange and blade shaft tie bolts may

cause parts to loosen and fall off.

• The blade shaft assembly weighs up to 500

pounds and must be lifted to a vertical

position to change blades.

• Failure to follow these instructions may

cause serious injury or death.

• Always wear protective gloves

when handling blades.

• Always let blades cool prior to

removing or replacing of

blades.

1. Remove the belt guard. There are 6 bolts

that must be removed using a 9/16”

Wrench or Socket.

2. Remove the blade shaft drive belts (2).Refer

to page __ for removal and installation.

3. Lower the saw until the blades make

contact with the ground using the lowering

button located on the right side of the

control handle.

4. Block the front and rear of the blade shaft

assembly with wooden block or similar to

ensure the blade shaft assembly does not

roll when bearing bolts are loosened.

5. Remover the depth stop wheels off the

front of the machine by removing the hex

nuts with a 1.50” wrench or socket.

6. Loosen and remover the 4 blade shaft

bearing bolts using a 3/4” wrench or socket.

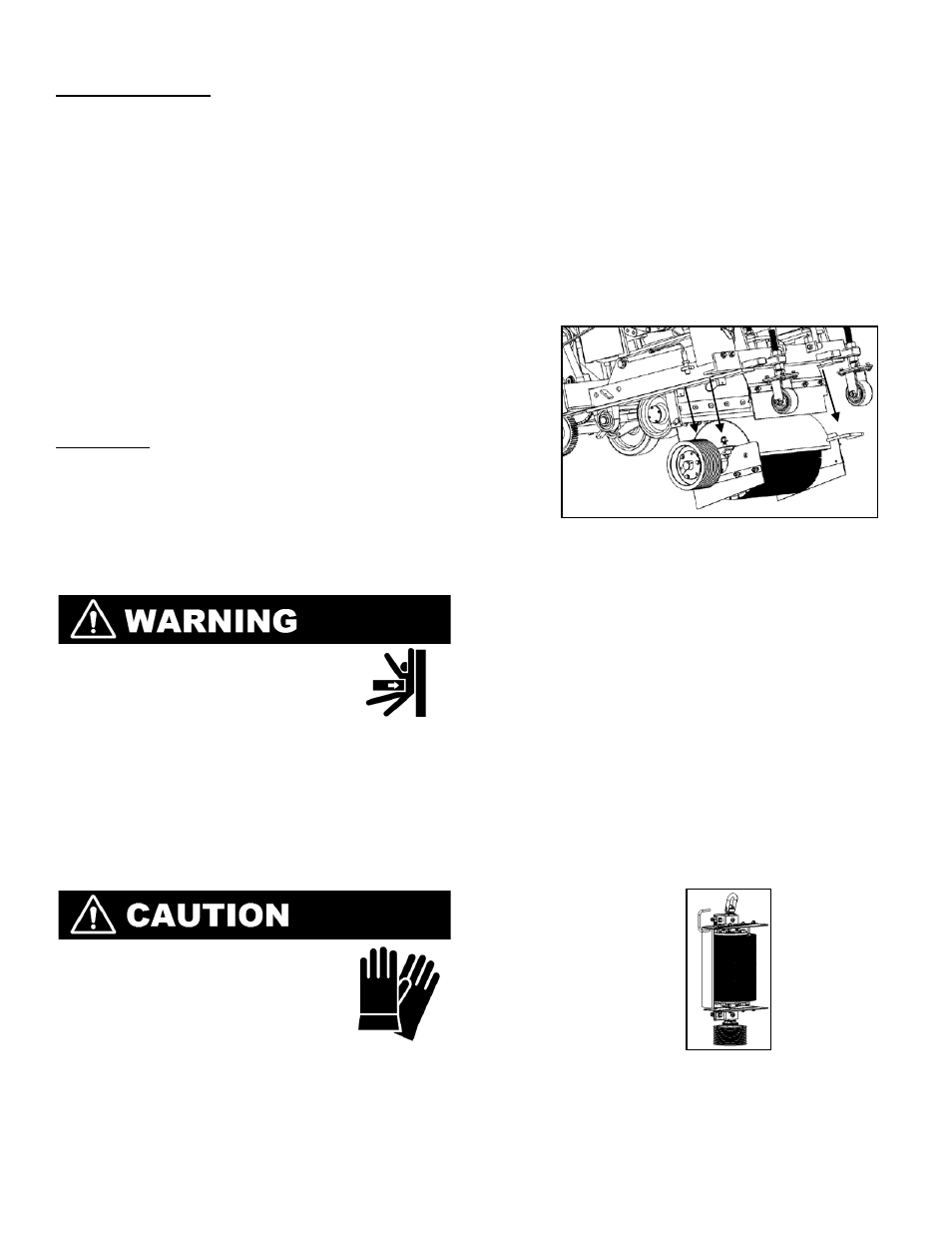

Carefully Lower Blade Shaft Assembly From Machine

7. Slowly raise the saw to the maximum height

using the raise (Left) pushbutton on the

speed lever.

8. Carefully remove chock blocks at the front

of the blade shaft assembly and slowly

remove the assembly, it should clear the

machine.

9. Using supplied hoist ring (2504720)

attached to the non sheave end of the

blade shaft. Make sure the ring is fully

seated in the threads and that threads are

clean and free of debris on the end of the

blade shaft. With a suitable lifting device

and proper capacity chain or cable, lift the

shaft and carefully set down on sheave end.

After securely setting in upright position,

remove hoist ring.

Place Blade Shaft Assembly on End Using Hoist Ring

10. Remove the revolving blade shield by

removing the hex head machine screws

located on the underside of the shield near

the bearings.

10