Diamond Products CG-2 Mini Groover User Manual

Page 21

6. Inspect the inside of the air cleaner

assembly. Clean away and loose debris

being careful not to get any debris inside

the intake tube.

7. Place filter back into air cleaner over safety

filter, and gently push into place till it feels

secure.

8. Place the end cap cover tightly back against

the end of the air cleaner housing and twist

clockwise and lock into place using tab.

Replacing the inner safety filter

The inner safety filter is not to be cleaned, replace

after five service cleanings of the primarily filter, or

every year. DO NOT operate saw without the

without this filter installed.

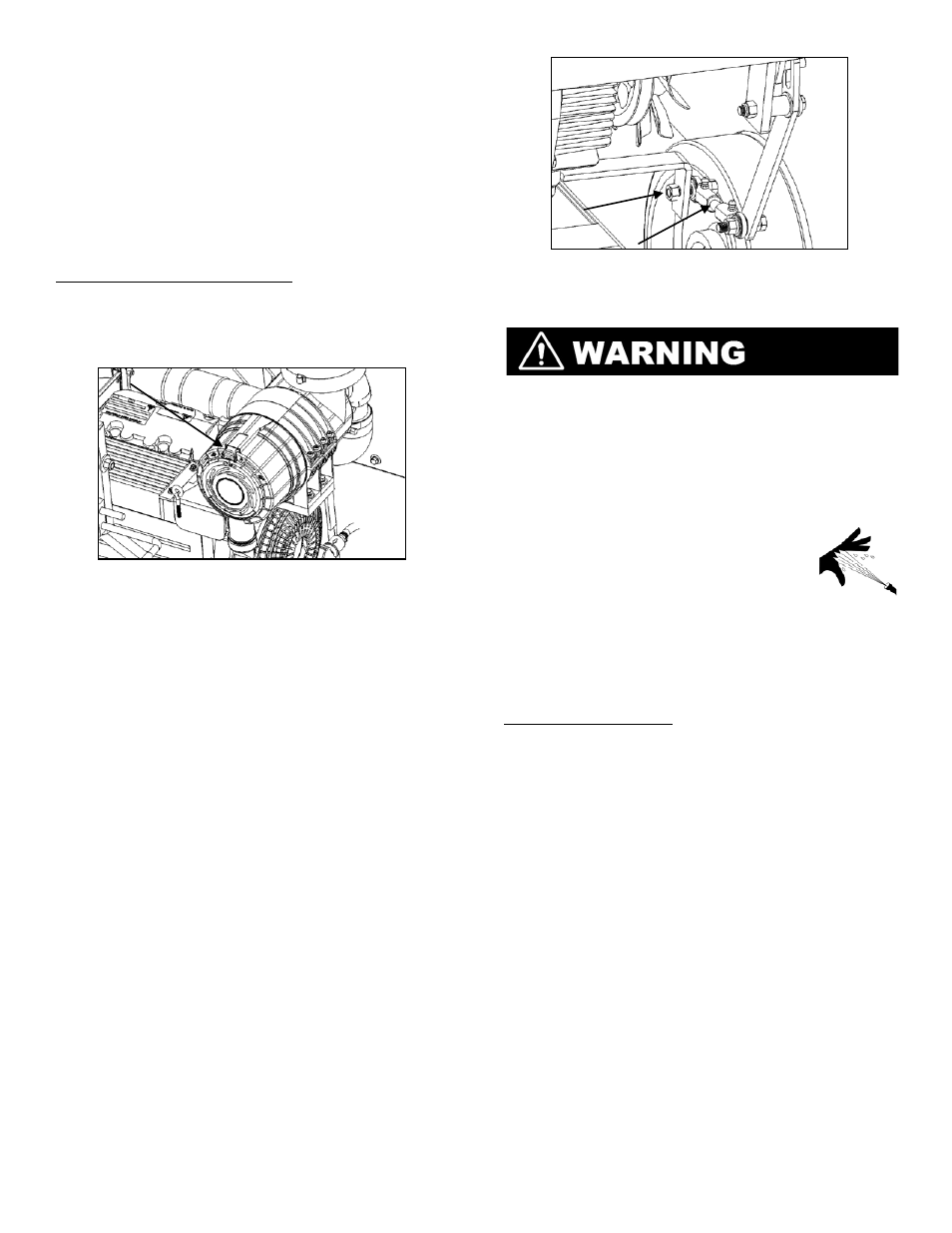

Air Cleaner End Cover Tab

Speed Control Lever

The speed control level generally requires little

maintenance. If the speed control lever is out of

sync with the saws movement, for example, if the

saw moves forward when in neutral, adjustment is

needed.

Adjusting the Speed Control Lever

1. Remove the rear cover panel from saw and

identify the linkage assembly connected to

the speed control lever.

2. Adjust the threaded link between the ball

joint connectors.

3. Remove any tools from area and start

engine to check for accuracy.

4. Turn engine off and readjust if necessary,

then replace rear body panel.

5. If desired, loosen or tight the lock nuts on

the ball joints pivot point to adjust the

friction felt when moving the control lever.

Linkage Assembly

Hydraulic System

• Turn off the engine prior to performing and

maintenance on the hydraulic system.

• Lower the saw to the floor so it is level to

release the pressurized hydraulic fluid in the

hydraulic system prior to performing and

maintenance or repairs.

• Visually inspect for, or use a piece of

cardboard under machine, for

any hydraulic fluid leaks. Keep

all body parts away from areas

that may eject hydraulic fluid.

Pressurized hydraulic fluid can penetrate

skin causing serious injury. IF skin is

punctured by hydraulic fluid, seek medical

attention immediately.

Adding Hydraulic Fluid

Check the hydraulic fluid level regularly and add

when necessary.

1. Open the access panel on top of the dash of

the saw.

2. Lower the saw to the ground so it is level

(this provides and accurate fluid level

reading).

3. Remove the breather cap on the top of the

hydraulic pump.

4. Add DEXTRON II automatic transmission

fluid when necessary.

NOTE: Filling the oil

to the top of the opening will cause fluid to

leak for the cap when the saw is lowered.

Fill oil to just below where the pipe begins

to extend out from the pump body to

prevent overfilling.

19