Diamond Products CG-2 Mini Groover User Manual

Page 20

when operating the saw, the magnetic sensor

needs to be adjusted or replaced.

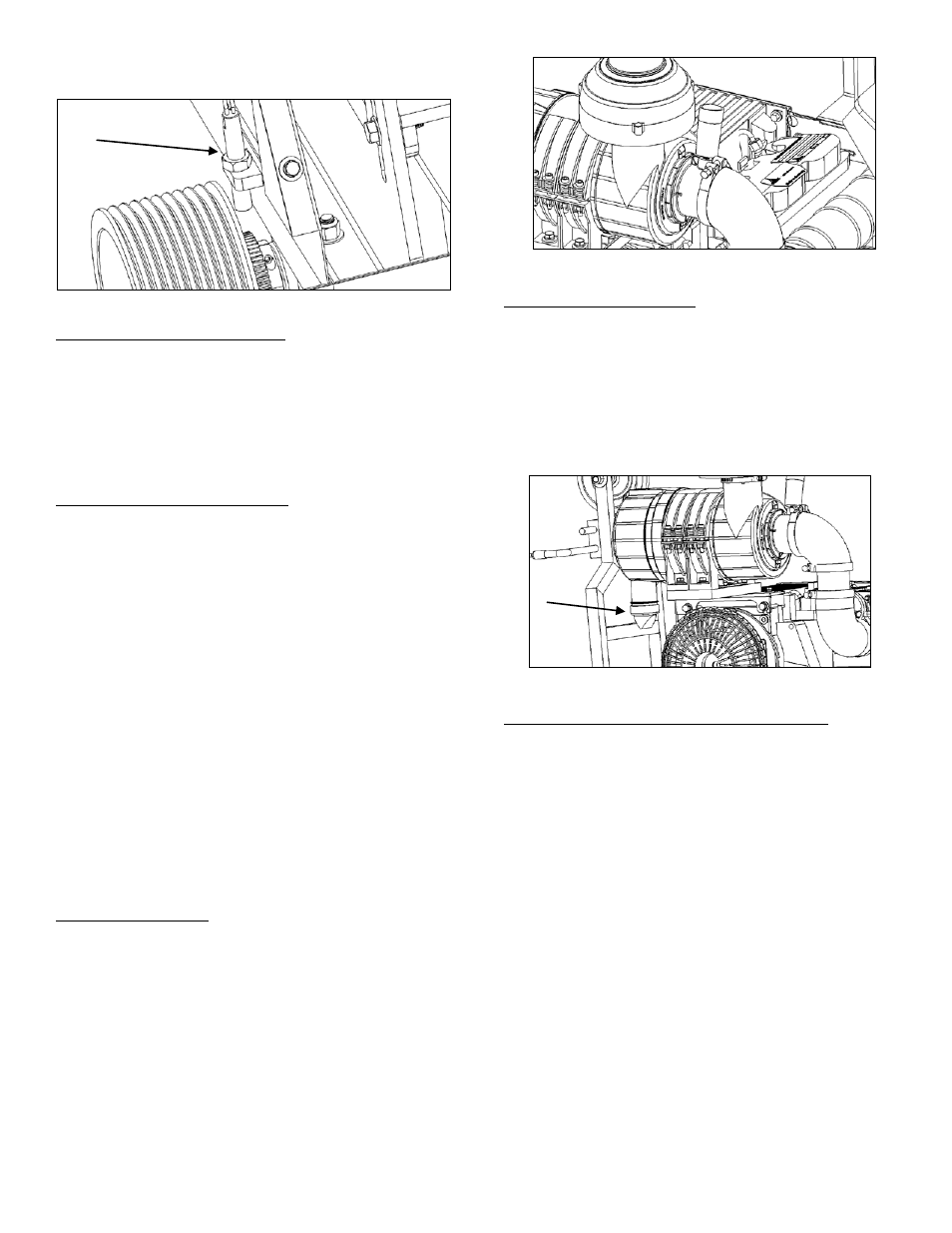

Magnetic Sensor Located Behind Blade Shaft Sheave

Adjusting the Magnetic Sensor

1. Loosen the jam nut on the magnetic sensor.

2. Turn the magnetic sensor clockwise until it

bottoms out (stops).

3. Turn the sensor counterclockwise exactly

one half turn.

4. Retighten the jam nut down the frame base

to secure sensor.

Replacing the Magnetic Sensor

1. Disconnect the battery.

2. Disconnect the magnetic sensors two wire

connector.

3. Loosen the jam nut on the sensor so it sits

near the upper part of the sensor, and turn

the sensor counter clockwise to remove it

from the base frame.

4. Place new sensor into the threaded hole

and tight sensor till it bottoms out (stops).

5. Turn the sensor one half turn

counterclockwise and secure the jam nut on

sensor to frame base.

6. Reconnect the battery.

Air Cleaner

Refer to the Deutz Operation manual as the

primary source for information on the air cleaner.

Restriction Indicator

Service the air cleaner as determined by the

restriction indicator to prevent unnecessary

damage to the engine, which decreases

maintenance cost and prolongs the life the engine.

• The restriction indicator service bar turns

red when the air cleaner requires service.

The chart on the restriction indicator

identifies the current restriction level in the

air cleaner.

• Press the reset button on the restriction

indicator to reset the unit after the air

cleaner has been serviced.

Restriction Indicator

Rubber Dust Ejector Boot

The rubber dust ejector boot valve ejects debris

and water when operating the saw. Occasionally

inspect and clean the ejector boot.

• Press inward on both sides of the ejector

boot near the valve opening to release

debris and water, and clean the valve

opening when necessary.

Rubber Dust Ejector Boot

Cleaning/Replacing the outer Primary Filter

The air filter contains a dry outer primary filter.

Service filter according to the restriction indicator

bar, and replace the filter annually.

DO NOT over-service or under-service the filter.

DO NOT operate saw without filter installed.

1. Pull the tab out on the air cleaners end

cover.

2. Turn the end cap clockwise to unlock the

cover, and pull the end cover away from the

air cleaner.

3. Pull out the primary filter from the air

cleaner and inspect it condition.

4. Move away from the saw and clean the

filter form the inside out using dry

compressed air (no more than 70 PSI) and

wash lightly with water to remove all debris

from filter.

5. Allow filter to completely dry before re-

installation.

18