3 calibration, 4 error and hardware malfunction messages, 5 resetting the instrument – Micromod Micro-DCI: 53ML5100 Manual Loader User Manual

Page 42: Alibration, Rror and, Ardware, Alfunction, Essages, Esetting the, Nstrument

53ML5100B Manual Loader

INSTRUCTION MANUAL

NOTE: When communicating with MicroMod for replacement of the main PCB, reference the

unit’s serial number to ensure the correct replacement assembly is supplied. The necessary ordering

information is provided on the instrument data tag and on the manufacturing specification sheet

supplied with that particular controller.

In the event of a hardware malfunction, a replacement PCB can be quickly substituted for the defective

assembly to minimize downtime. Contact MicroMod for instructions before returning equipment.

The defective PCB should be carefully packaged and returned, shipping charges prepaid, to the Repair Dept.

of MicroMod Automation. Do not wrap PCBs in plastic, as it can cause static damage. It is suggested that

the defective PCB be returned in the special bag in which the replacement module was supplied.

5.3 Calibration

The instrument’s analog inputs (ANI0-3) and output (ANO0) are extremely stable. They normally do not

require recalibration. If it becomes necessary to recalibrate the instrument, due to the inadvertent change of

the stored calibration values, then this can be accomplished by altering their respective datapoints. The

calibration span and

zero datapoint locations are as follows:

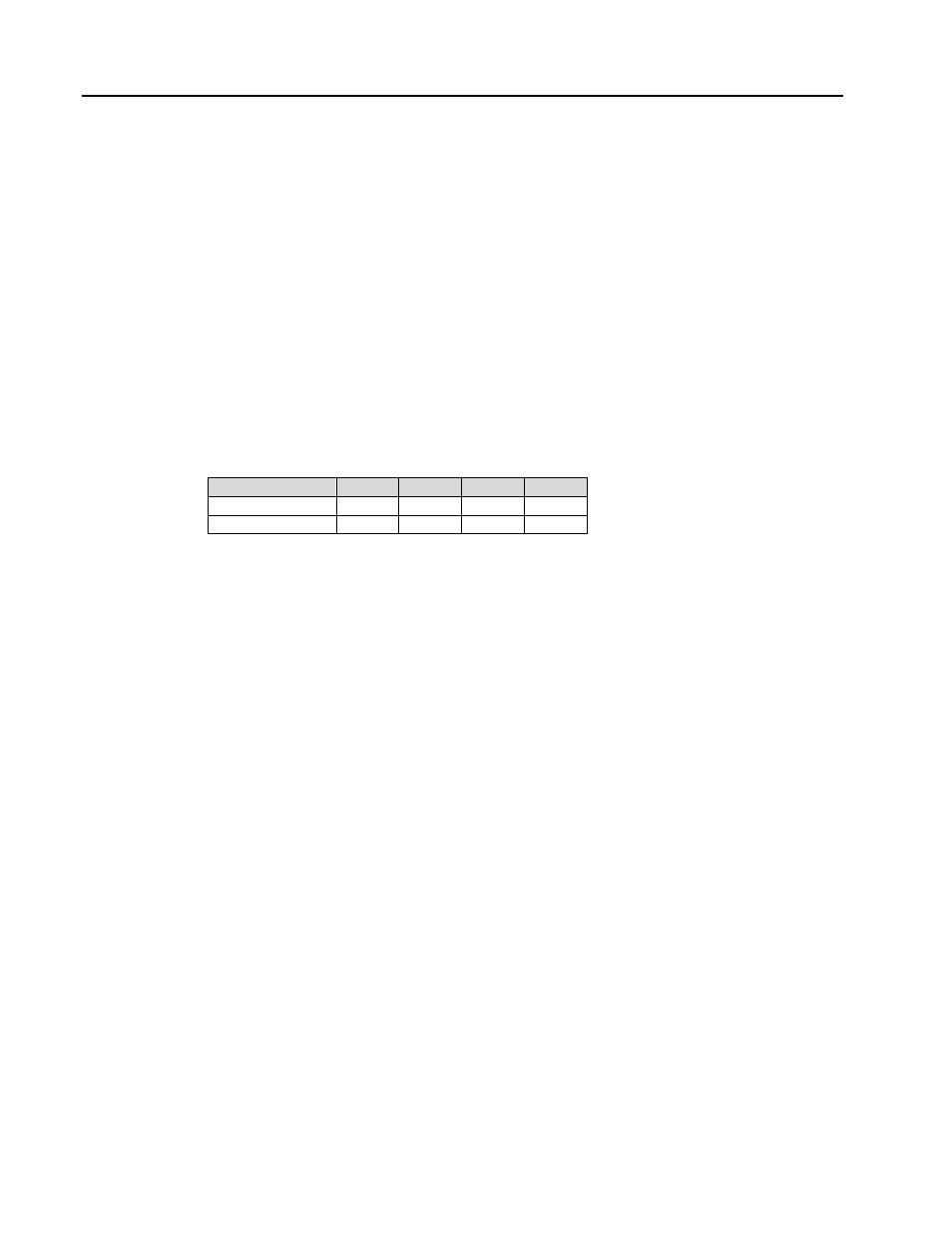

ANI0

ANI1

ANO0 ANO1

Calibrate Zero

B263

B264

B267

B268

Calibrate Span

C296

C297

C300

C301

NOTE: The spans have a nominal value of 1.0 and can

be adjusted up or down within the range of 0.8 to 1.2. The

zeros have a nominal value of 128 and can be adjusted up

or down within the range of 100 to 150.

5.4 Error and Hardware Malfunction Messages

Entire Display Flashes - The watchdog timer has timed out.

CPU RAM FAILURE - IC U1 is bad.

ROM CHKS FAILURE - IC U3 is bad.

5.5 Resetting the Instrument

The instrument can be reset either by cycling the power, or by carefully pressing the reset button by inserting

a thin wire, such as a paper clip, through the small hole in the upper left corner of the front bezel. (See Figure

1-2 for the location of the reset hole.) When the instrument restarts, it immediately checks to determine if any

of the horizontal keypad push buttons are held pressed.

If

the

F1 push button is held pressed during instrument reset, the instrument enters a factory test

mode. The test mode can be exited by resetting the instrument again using the thin wire with no push

buttons pressed.

If

the

F2 push button is held pressed during instrument reset, the instrument database is set to the

defaulted values.

38