Troubleshooting – Liquid Controls M-MA Meters User Manual

Page 22

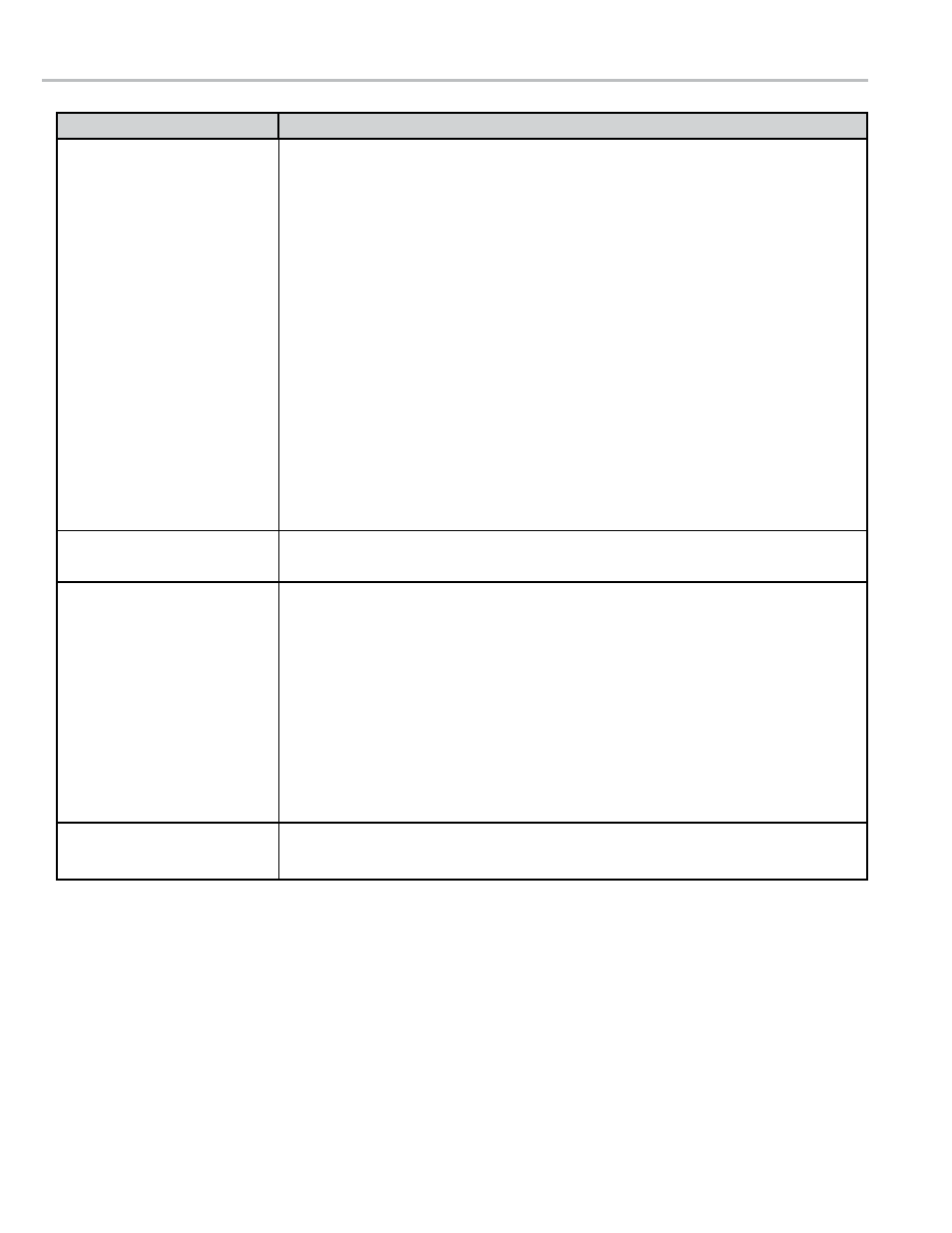

troubleshootInG

probleM

probable cause & solutIon

Leakage past packing gland

drive shaft housing from

internal metering chamber

Internal seal of packing gland assembly is worn. Replace packing gland and

O-ring seal.

OPERATING NOTE

Two common causes of packing gland leakage are thermal expansion and hydraulic shock.

Thermal expansion can occur when two valves in a piping system, on either side of the meter,

are closed at the same time and the temperature in the system rises. As little as a 1°F increase

in temperature can drive the system pressure to a point that exceeds the maxiumum working

pressure rating of the meter. To avoid any damage caused by thermal expansion, a pressure-

relief valve of some kind must be installed in the system.

Hydraulic shock occurs when a large volume (mass) of liquid is flowing through the system

and a valve suddenly closes. When the flow is stopped, the entire mass of the liquid in the

piping system rams into the components within the meter. The greater the length of line (more

line length equals more liquid mass) and the greater the velocity of the liquid, the greater the

hydraulic shock. Since the valve is usually located at the meter outlet, the meter housing,

packing gland and the meter internal are subject to the full impact of such hydraulic shock. To

prevent hydraulic shock, a slow closing two-stage valve should be used with the meter. On

systems where mass length of line and velocity are of a magnitude that preclude the elimination

of hydraulic shock with the use of a two-stage slow closing valve, an impact-absorbing air

cushioning device can be added to further dampen hydraulic shock.

Leakage from the cover

gasket

Gasket has been damaged due to shock pressure or cover bolts have not been

tightened sufficiently. Replace gasket and tighten cover bolts correctly.

Product flows through

meter but the register does

not operate

A. Check packing gland, and gear train.

B. If all meter parts are moving then problem is in register. Faulty register should

be checked and repaired by trained mechanic.

C. Remove register from meter. If all meter parts are moving but output shaft of

adjuster assembly is not, adjuster is worn and must be replaced.

D. If totalizer numerals (small numbers) on register are recording, but the big

numerals are not moving, register needs repair.

E.

Packing gland gear not turning. Replace the packing gland. This may be

caused by starting the flow too rapidly.

For M-60 and M-80 meters, the drive blade may be sheared.

Breaking teeth on timing

gears

A. Starting or stopping flow in meter too rapidly.

B. Pump bypass not adjusted properly.

22