Reassembling the meter – Liquid Controls M-MA Meters User Manual

Page 19

reasseMblInG the Meter

Rotor Keys

reassembling the Meter

to reassemble the bearing plates and rotors:

continued from following page

4. The rotors should have a small amount of end-play and

be easy to turn. Test each rotor, one at a time. Turn the

rotors to make sure that they revolve freely. Jog the rotors

from end to end to check for end-play. If they do not move

easily in both tests, remove the rotors and check for

burrs and corrosion deposits. Clean them thoroughly and

repeat steps 2, 3 and 4.

5. Each rotor has a notch, or “keyway”, to hold a rotor key.

The rotor key is a small wedge of metal. Press a rotor

key into the keyway of each rotor with your thumb and

forefinger.

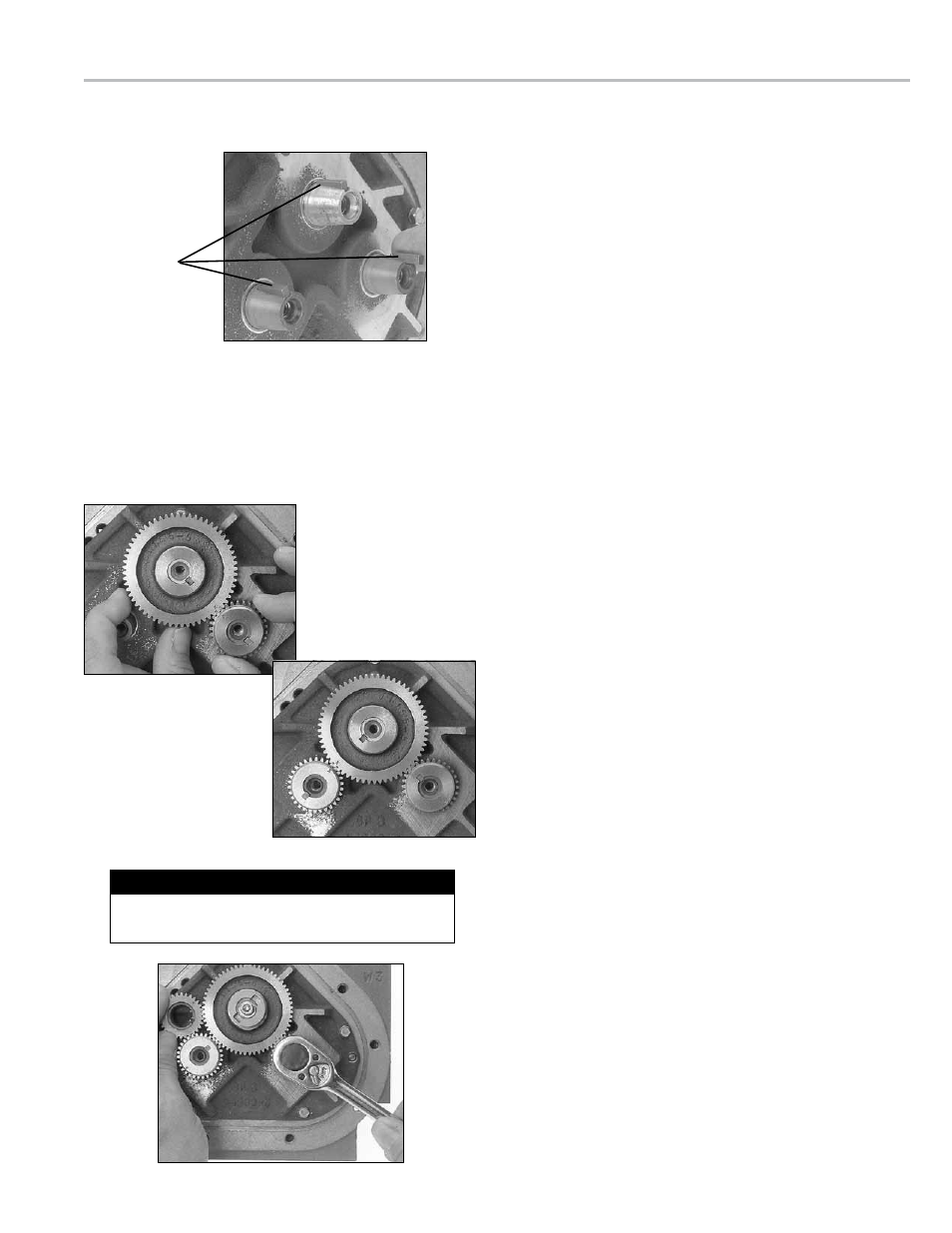

to time the rotor gears:

1. Slide the blocking rotor gear over the tapered blocking

rotor end and turn it until the timing mark is in position

to line up with the timing mark on the right displacement

rotor gear. Slide the right displacement rotor gear over

the tapered end of the rotor so that the timing mark lines

up with the blocking rotor gear timing mark.

2. Turn the blocking rotor gear (turn the right displacement

rotor gear with it) until the timing mark is in position to

line up with the timing mark on the left displacement

rotor gear. Slide the left displacement rotor gear over the

tapered end of the rotor so that the timing mark lines up

with the blocking rotor gear timing mark.

3. Position the spare displacement rotor gear between

the left displacement rotor gear and the blocking rotor

gear to prevent the gears from moving. Attach the right

displacement gear washer and screw using the rotor gear

wrench.

4. Keep the spare displacement rotor gear positioned by the

left displacement rotor gear. Attach the left displacement

gear washer and screw using the rotor gear wrench.

5. Position the spare displacement rotor gear between the

right displacement rotor gear and the blocking rotor gear.

Attach the blocking rotor gear with the packing gland

driver and screw using the rotor gear wrench.

6. Rotate the gears to make sure that the rotors turn freely.

Burrs, foreign material, or marred surfaces can restrict the

rotor movements. If the rotors do not turn freely, remove

the gears and rotors and deburr and clean the surfaces

again.

tIMInG the rotor Gears

Before putting the meter into service, the rotors must be timed. Rotors are timed by lining up timing marks stamped

onto the face of the gears. The timing mark on the blocking rotor gear is stamped on a gear tooth. The timing mark on

the displacement rotor gears is stamped on a space between two gear teeth. You may need to remove the gears and

reposition them several times to line up the timing marks correctly.

Tighten the gear screws to the torque specification

listed in the Torque Chart on page 22.

Torque the Gear Screw

19