Controlled Products Systems Group RANGER User Manual

Page 9

7

Ranger actuator support bracket and actuator

bracket are standard and require welding to install

Figure 2A

4”

7”

Direction of gate

movement when opening

Shown in Closed position

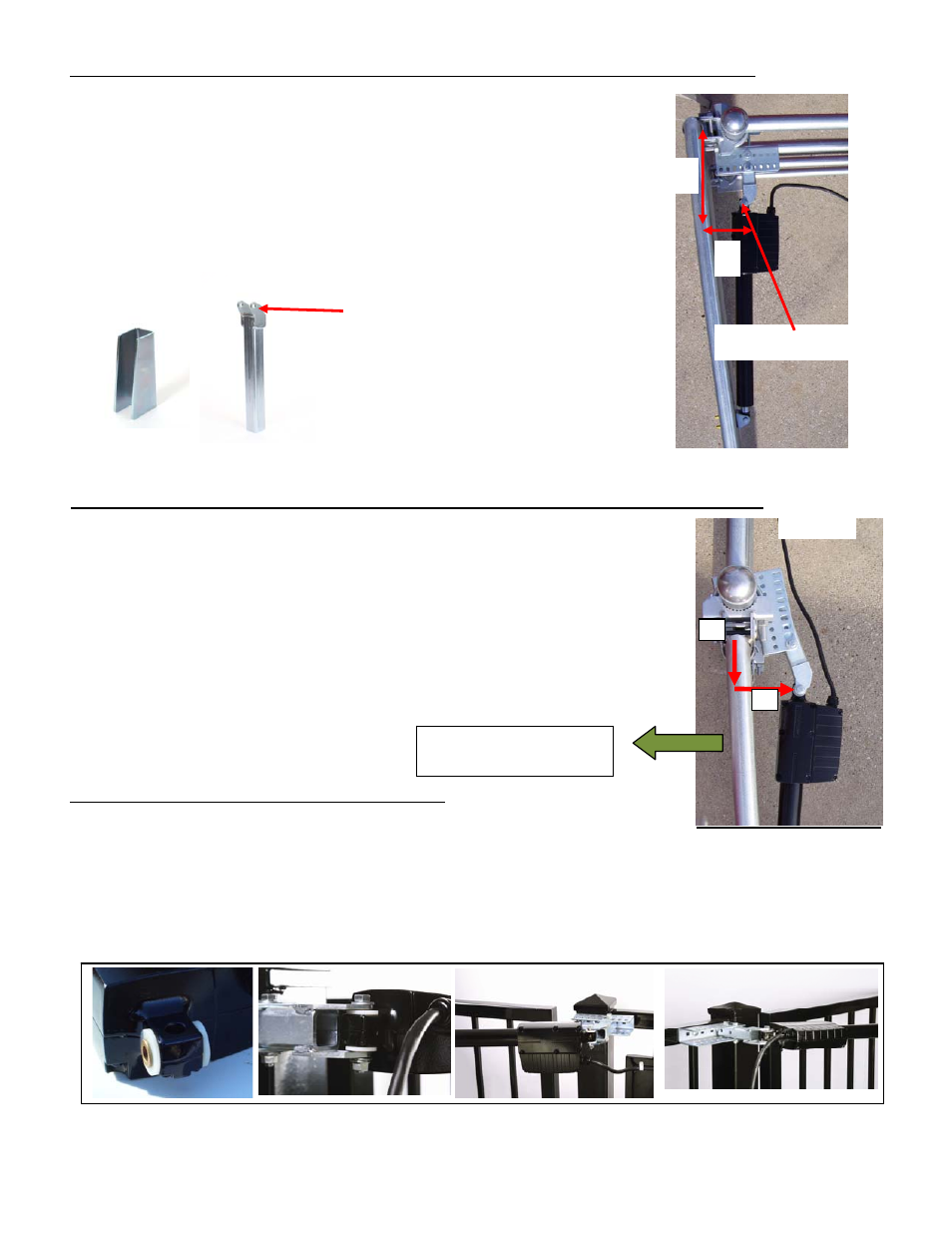

Installing Actuator Support Bracket & Actuator Bracket (Pull To Open)

* B o l t o n b r a c k e t s s h o w n o p t i o n a l

The picture in figure 2 is a Pull to Open installation. When

determining the location of the actuator pivot point all

measurements should be made from the center of the hinge.

The dimensions for a typical 90 degree opening are 5” behind the

hinge center and 7” toward the inside of the property.

Measurements are from hinge center, there are many types of hinges available.

Make measurements from the hinge center.

Installing Actuator Support Bracket & Actuator Bracket (Push To Open)

* B o l t o n b r a c k e t s s h o w n o p t i o n a l

The picture in figure 2A is a Push to Open installation. When determining

the location of the actuator pivot point all measurements should

be made from the center of the hinge.

The dimensions for a typical 90 degree opening are 4” behind the

hinge center and 7” toward the driveway from hinge center. This

type of installation places the bracket out slightly toward the

drive.

Installing Linear Actuator to Actuator Bracket

See figure 3 (Bolt on brackets shown are optional)

1. Install nylon washers and bronze bushings into rear of linear actuator.

2. Install into actuator bracket

3. Secure in place using 3/8 x 2 ½” shoulder bolt and two 3/8 SAE washers.

4. Use 3/8 serrated hex nut to secure, tighten firmly. Do not over tighten.

Important: Actuator should swing freely, Do not over tighten.

Figure 3

Actuator pivot point

5

”

7

”

Actuator pivot point

Gate shown in the full open position

Figure 2