Troubleshooting – Controlled Products Systems Group HTG 320-2 ST User Manual

Page 54

StrongArm Installation and Reference

44

Troubleshooting

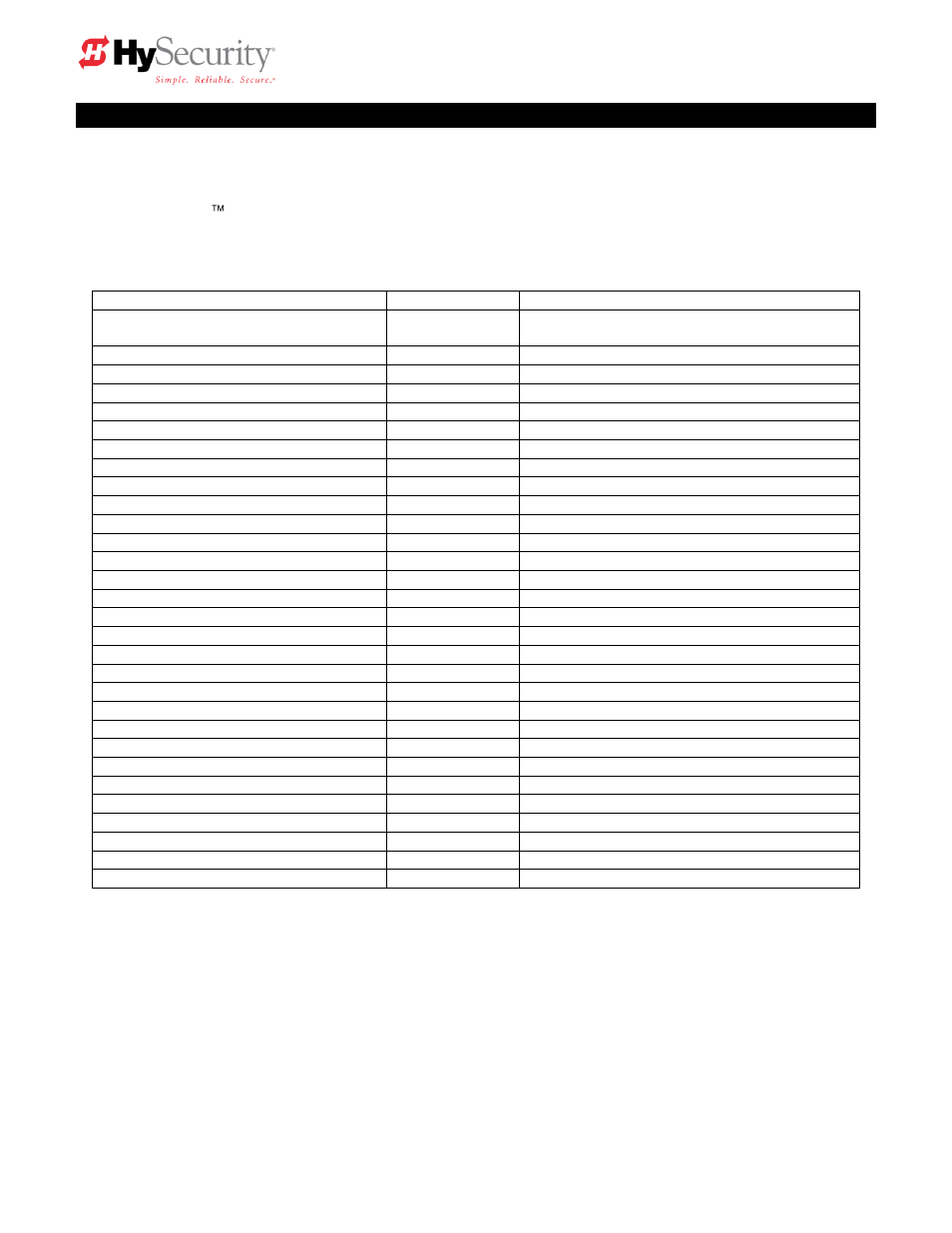

The Smart Touch Controller system includes many self diagnostic capabilities. The LCD will display specific

messages and the Audio Alert buzzer will sound distinctive chirps. Any Alerts, Faults or Errors are also logged into

a memory and stamped with a time and date. For diagnostic purposes, these messages can be retrieved with

optional WinLogger software available from HySecurity Gate.

The following chart is a listing of codes that would appear on the LCD display if problems are detected by

the Smart Touch Controller.

Error, Fault, or Alert Status

LCD Display

Buzzer Chirp Sequence

Cannot respond due to tripped sensor

or in Entrapment mode

Entr

2 chirps/sec every 2 seconds while control

input is active

Safety Mode Alert

SAFE

2 chirps once when in Safety Mode

Low 24V Control Voltage Alert

Lo24 (ac or dc)

N/A (display flashes 1 sec every 5 seconds)

Critical Low 24V supply power

BadP (ac or dc)

N/A Display steady

– controls disabled

Dead 24V Battery Alert

–DC only

bat - dEAd

3 chirps upon any operating command

Gate forced open Alert

ALE1

2 pulses/sec for 30 seconds

Gate drift closed Alert

ALE2

2 pulses/sec for 10 seconds

Motor thermal overload Alert

ALE4

2 chirps/sec every 15 seconds

Limit not released in 10 seconds

ALE6

2 chirps/sec every 15 seconds

Loop abnormal freq change alert

ALE7

2 chirps/sec every 15 seconds

Loop shorted to ground alert

ALE8

2 chirps/sec every 15 seconds

Loop disconnected alert

ALE9

2 chirps/sec every 15 seconds

Loop detector comm. alert

AL10

2 chirps/sec every 15 seconds

Loop detector function alert

AL11

2 chirps/sec every 15 seconds

Loop detector active >5 minutes

AL12

2 chirps/sec every 15 seconds

General I2C comm. buss failure

AL16

2 chirps/sec every 15 seconds

Bad 3V coin battery

AL17

2 chirps/sec every 15 seconds

Lock Interlock (Input #22) Blocks Open

AL17

2 chirps/sec every 15 seconds

Maximum run Fault

FAL1

1 chirp once every 15 seconds

Photo eye Fault (supervised)

FAL2

2 chirps/sec once per minute

Critical AC sag

– bad supply wire

FAL3

2 chirps/sec once per minute

Directional motion Error

Err1

3 chirps/sec once per minute

Disconnected IES Error

Err2

3 chirps/sec once per minute

Loop detector failed

Err3

3 chirps/sec once per minute

Master/slave RS485 comm. Error

Err4

3 chirps/sec once per minute

EEPROM Data Error (factory)

Err7

3 chirps/sec once per minute

EEPROM Data Error (installer)

Err8

3 chirps/sec once per minute

EEPROM Data Error (user menu)

Err9

3 chirps/sec once per minute

Program Data Error

FAiL

3 chirps/sec once per minute

The green LED (near terminal #24 on Classic Controllers or near the “coin” battery on New Generation

Controllers) is the heartbeat of the processor. This LED should always blink brightly to indicate normal

operation.

GATE SPEED: The speed in which a hydraulic operator moves a gate is determined by the size of the pump and

the size of the actuator components. Just like a gear box, this speed is not adjustable. Attempting to slow a gate by

changing any valve setting will cause a great deal of inefficiency and heat. If the speed of a gate must be changed,

contact your HySecurity distributor. Extremely cold weather is unlikely to seriously affect the speed of the gate,

because HySecurity employs a special grade of hydraulic oil that we call UNIFLOW oil, which maintains a very

linear viscosity over a broad range of temperatures. Because of this high quality oil and other design

considerations, we rate our operators for service in ambient temperatures of

–40F degrees to 130F degrees. If the

speed of your operator has been affected by cold weather, verify that the gate

hardware s not impaired by ice and

verify that the reservoir it is filled with UNIFLOW oil. In severe conditions, consider adding a heater.