Controlled Products Systems Group 107725 User Manual

Page 9

Page 9

June, 2004

750 Operator And

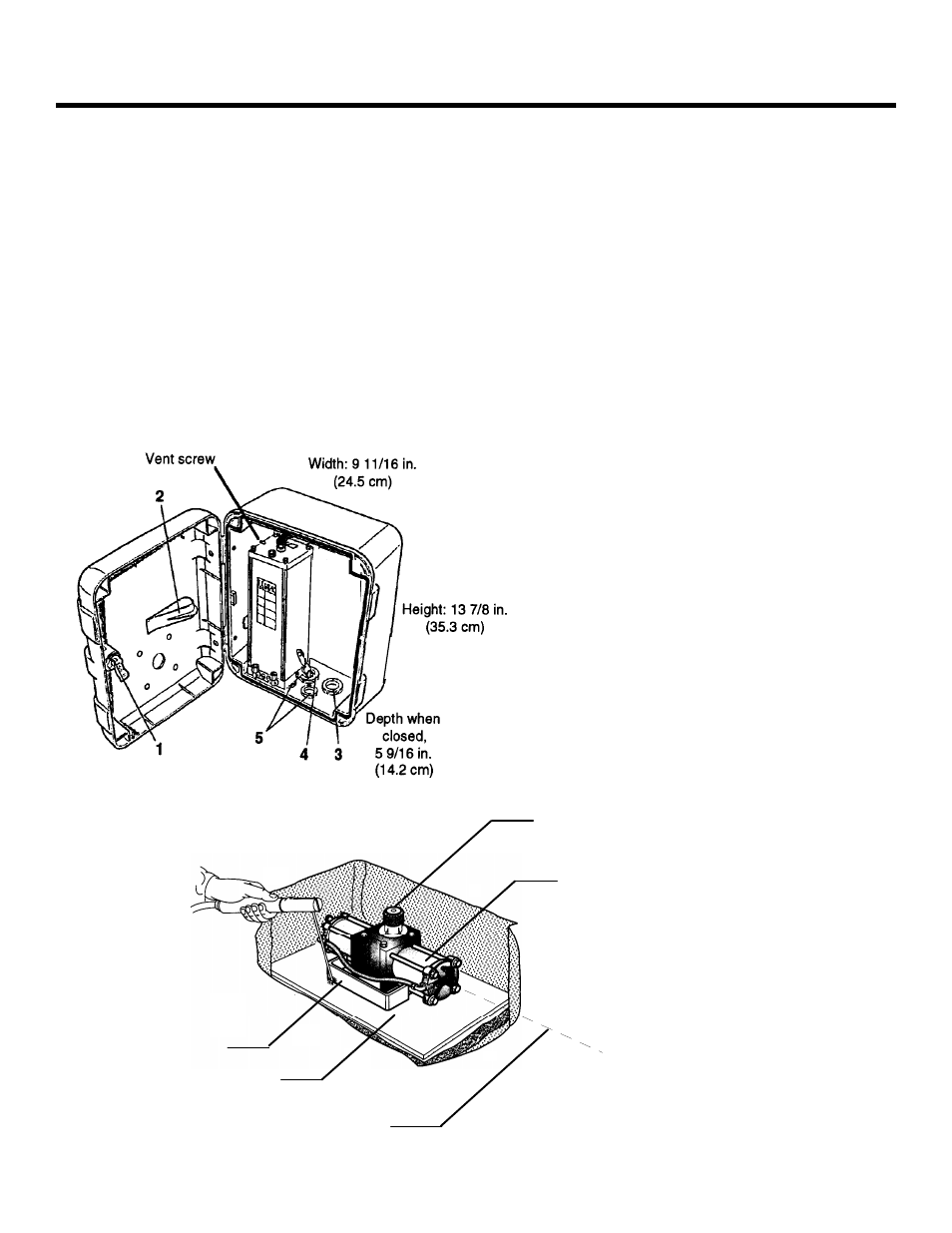

455 D Control Panel Installation Manual

Figure 5. Parts of the Power Unit in the vinyl box

Caution: NEVER weld the base plate of the drive unit

to the foundation plate. Weld only the mounting C

brackets to the foundation plate.

When the position of the drive unit meets these

conditions, weld the C-shaped mounting brackets to the

foundation plate to hold the drive unit in position (see

Figure 6).

Next you need to prepare the two L-shaped "box halves"

for installation. Note that the lip on each piece should

be on top so as to support the top cover. Make the

necessary holes for the two hydraulic lines that run

from the drive unit to the power unit.

Once you have made your access holes, you can weld

the box halves to the foundation plate and to one

another so as to enclose the drive unit on four sides. Be

sure to protect the drive unit during welding.

I

NSTALL

THE

D

RIVE

U

NIT

To install the drive unit, first make sure the four

leveling bolts on the base of the unit do not protrude

from the bottom of the unit. Then place the unit on the

foundation plate (see Figure 6).

Position the drive unit according to the following:

The side of the drive unit with the splined shaft should

be the side nearest the gate post.

The longitudinal axis of the drive unit is perpendicular

to (at right angles to) the fully closed gate leaf.

The center of the splined shaft is vertically aligned with

the center of the gate hinge axis (use a plumb line).

6

1 Lock for triangular key

2 Clip to hold instruction manual

3 1 1/16 in. (3 cm) holes for hydraulic lines

4 1 1/16. in (3 cm) knock-outs

5 Three knock-outs, each measuring

3/4 in. (2 cm)

Splined shaft: This side

of the drive unit should be

nearest the gate post.

Drive unit

Foundation

plate

Mounting

C bracket

Longitudinal axis

of the drive unit

Figure 6. Welding the mounting C-bracket

to the foundation plate