Npacking, Perator – Controlled Products Systems Group 107725 User Manual

Page 5

Page 5

June, 2004

750 Operator And

455 D Control Panel Installation Manual

U

NPACKING

THE

O

PERATOR

When you receive your 750 Operator, complete the

following steps:

Inspect the shipping box for physical damage such as

leaking oil or a torn carton. Then inspect the operator

after you remove it from the box. Notify the carrier

immediately if you note any damage because the carrier

must witness the damage before you can file a claim.

As you unpack the boxes, insure that all parts listed

below are included:

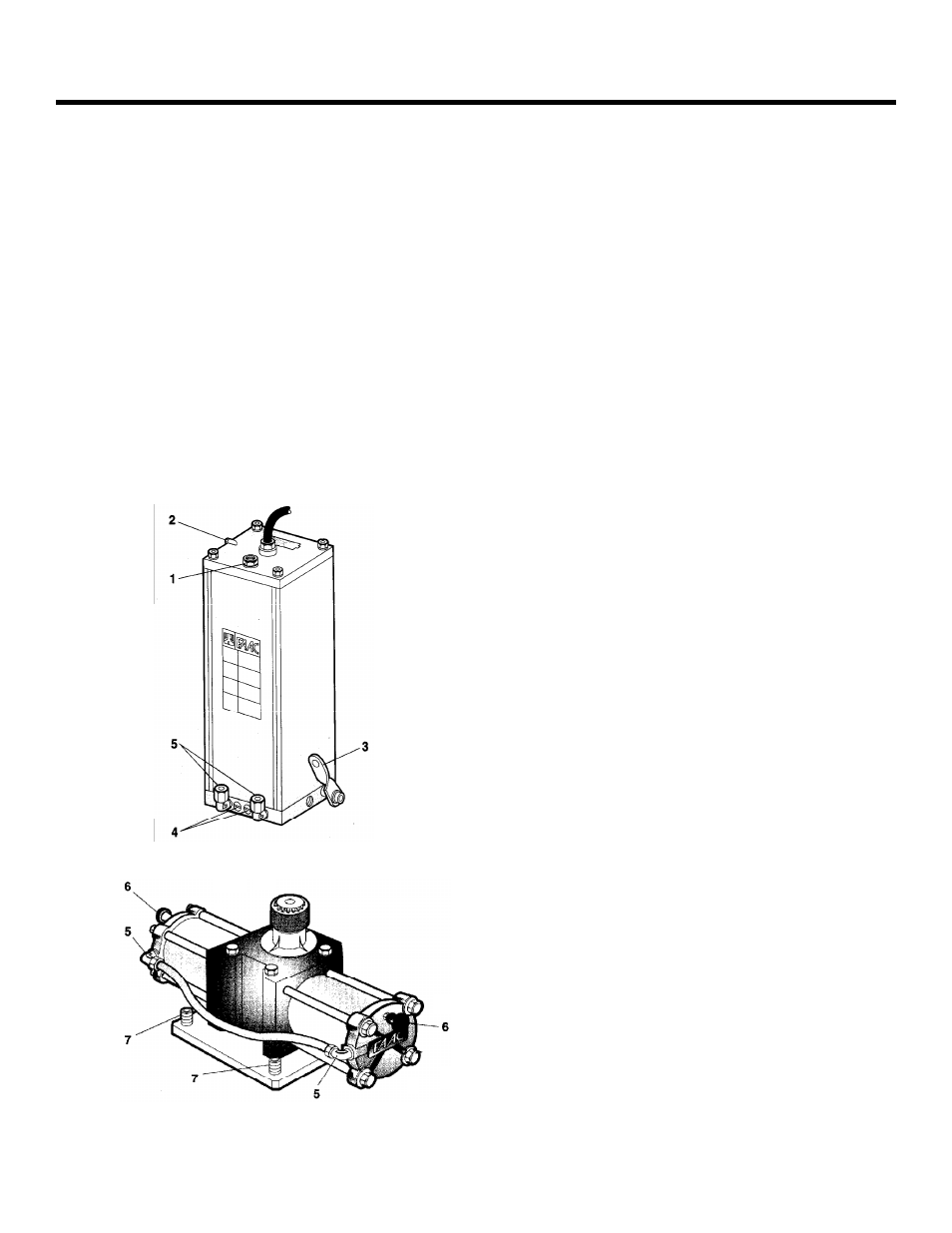

Power Unit (see figure 1a):

(1) vinyl box with key (the power unit is shipped

separately from the box)

Drive Unit (see figure 1b):

(1) Hydraulic drive attached to its base plate with four

(4) leveling bolts installed and with the sleeve fitted

over the splined shaft.

(2) “Box halves” (right-angled and lipped pieces of

galvanized steel that together form the sides of the

box around the drive unit)

(1) Top cover protected by peel-off plastic

(1) Package containing two (2) mounting C-brackets, six

(6) screws to hold cover on the drive unit, four (4)

ring fittings for hydraulic lines, one (1) plastic half-

sleeve to fit around drive shaft and match top cover,

one 0.3-qt (1/4 liter) container of hydraulic fluid

(1) Plastic collar around splined shaft

(a)

(b)

1 Oil Plug/Dip Stick

2 Vent

Screw

3 Manual Release Lever

4 By-Pass Valve Screw

5 Hydraulic 90-deg Elbow Couplings

6 Bleed

Screws

7 Leveling

Bolts

Figure 1. Parts of the 750(a) the Power Unit and (b) the Drive Unit

(sometimes referred as to the Ram Unit)